- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Silicon Carbide Coated Manufacturers, Suppliers, Factory

SiC coating is a thin layer onto the susceptor through the chemical vapor deposition(CVD) process. Silicon carbide material provides a number of advantages over silicon, including 10x the breakdown electric field strength, 3x the band gap, which provides the material with high temperature and chemical resistance, excellent wear resistance as well as thermal conductivity.

Semicorex provides customized service, help you innovate with components that last longer, reduce cycle times, and improve yields.

SiC coating possesses several unique advantages

High Temperature Resistance: CVD SiC coated susceptor can withstand high temperatures up to 1600°C without undergoing significant thermal degradation.

Chemical Resistance: The silicon carbide coating provides excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents.

Wear Resistance: The SiC coating provides the material with excellent wear resistance, making it suitable for applications that involve high wear and tear.

Thermal Conductivity: The CVD SiC coating provides the material with high thermal conductivity, making it suitable for use in high-temperature applications that require efficient heat transfer.

High Strength and Stiffness: The silicon carbide coated susceptor provides the material with high strength and stiffness, making it suitable for applications that require high mechanical strength.

SiC coating is used in various applications

LED Manufacturing: CVD SiC coated susceptor is used in manufacturing processed of various LED types, including blue and green LED, UV LED and deep-UV LED, due to its high thermal conductivity and chemical resistance.

Mobile communication: CVD SiC coated susceptor is a crucial part of the HEMT to complete the GaN-on-SiC epitaxial process.

Semiconductor Processing: CVD SiC coated susceptor is used in the semiconductor industry for various applications, including wafer processing and epitaxial growth.

SiC coated graphite components

Made by Silicon Carbide Coating (SiC) graphite, the coating is applied by a CVD method to specific grades of high density graphite, so it can operate in the high temperature furnace with over 3000 °C in an inert atmosphere, 2200°C in vacuum.

The special properties and low mass of the material allow fast heating rates, uniform temperature distribution and outstanding precision in control.

Material data of Semicorex SiC Coating

|

Typical properties |

Units |

Values |

|

Structure |

|

FCC β phase |

|

Orientation |

Fraction (%) |

111 preferred |

|

Bulk density |

g/cm³ |

3.21 |

|

Hardness |

Vickers hardness |

2500 |

|

Heat Capacity |

J·kg-1 ·K-1 |

640 |

|

Thermal expansion 100–600 °C (212–1112 °F) |

10-6K-1 |

4.5 |

|

Young’ s Modulus |

Gpa (4pt bend, 1300℃) |

430 |

|

Grain Size |

μm |

2~10 |

|

Sublimation Temperature |

℃ |

2700 |

|

Felexural Strength |

MPa (RT 4-point) |

415 |

|

Thermal conductivity |

(W/mK) |

300 |

Conclusion CVD SiC coated susceptor is a composite material that combines the properties of a susceptor and silicon carbide. This material possesses unique properties, including high temperature and chemical resistance, excellent wear resistance, high thermal conductivity, and high strength and stiffness. These properties make it an attractive material for various high-temperature applications, including semiconductor processing, chemical processing, heat treatment, solar cell manufacturing, and LED manufacturing.

- View as

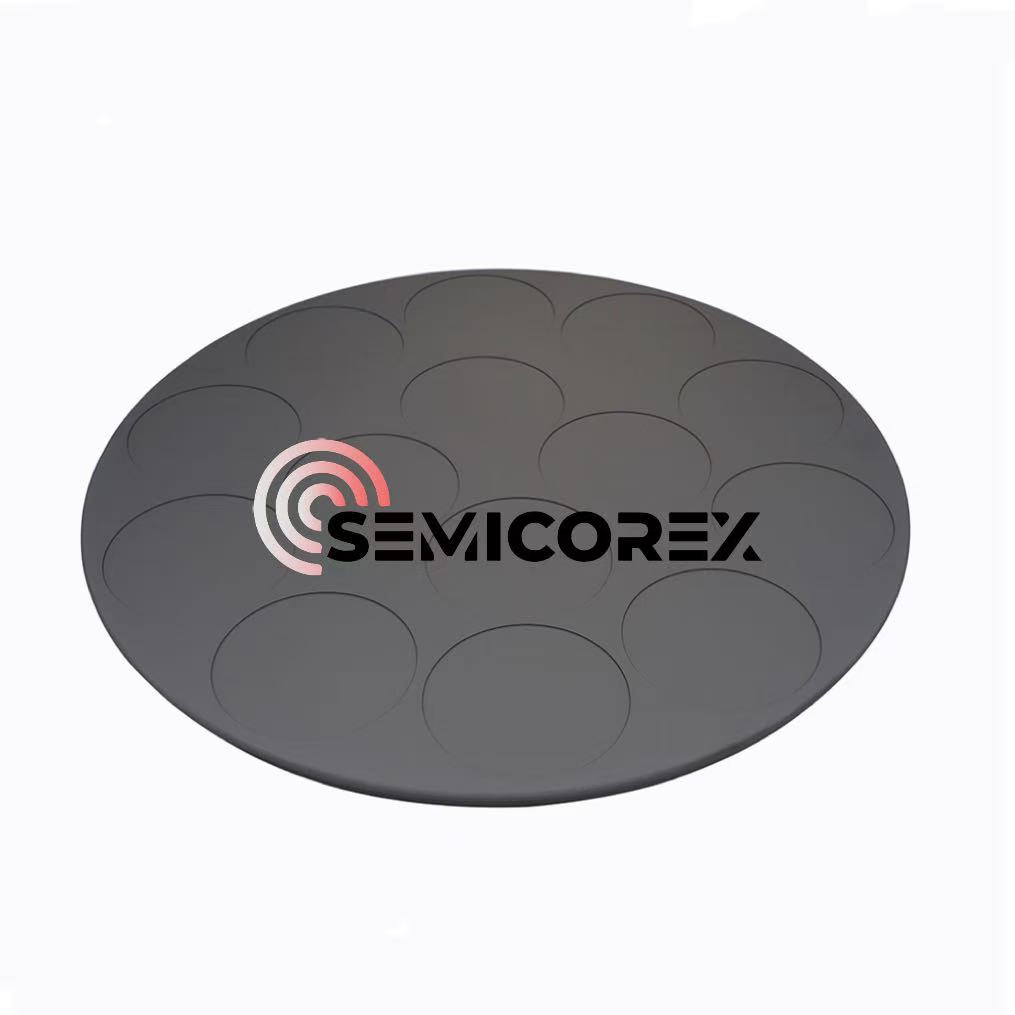

SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold ......

Read MoreSend InquirySiC Coated Graphite Tray

SiC coated graphite tray is a cutting-edge semiconductor part that gives Si substrates precise temperature control and stable support during the silicon epitaxial growth process. Semicorex always give top priority to customer demand, providing customers with core component solutions required for the production of high-quality semiconductors.

Read MoreSend Inquiry8 inch EPI Top Ring

Semicorex 8 inch EPI Top Ring is a SiC coated graphite component designed for use as the upper cover ring in epitaxial growth systems. Choose Semicorex for its industry-leading material purity, precise machining, and consistent coating quality that ensure stable performance and extended component life in high-temperature semiconductor processes.*

Read MoreSend Inquiry8 inch EPI Bottom Ring

Semicorex 8 inch EPI Bottom Ring is a robust SiC coated graphite component essential for epitaxial wafer processing. Choose Semicorex for unmatched material purity, coating precision, and reliable performance in every production cycle.*

Read MoreSend Inquiry8 inch EPI Susceptor

Semicorex 8 Inch EPI Susceptor is a high-performance SiC-coated graphite wafer carrier designed for use in epitaxial deposition equipment. Choosing Semicorex ensures superior material purity, precision manufacturing, and consistent product reliability tailored to meet the demanding standards of the semiconductor industry.*

Read MoreSend InquirySiC Carrier for ICP

Semicorex SiC Carrier for ICP is a high-performance wafer holder made of SiC-coated graphite, designed specifically for use in inductively coupled plasma (ICP) etching and deposition systems. Choose Semicorex for our world-leading anisotropic graphite quality, precision small-batch manufacturing, and uncompromising commitment to purity, consistency, and process performance.*

Read MoreSend Inquiry