- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

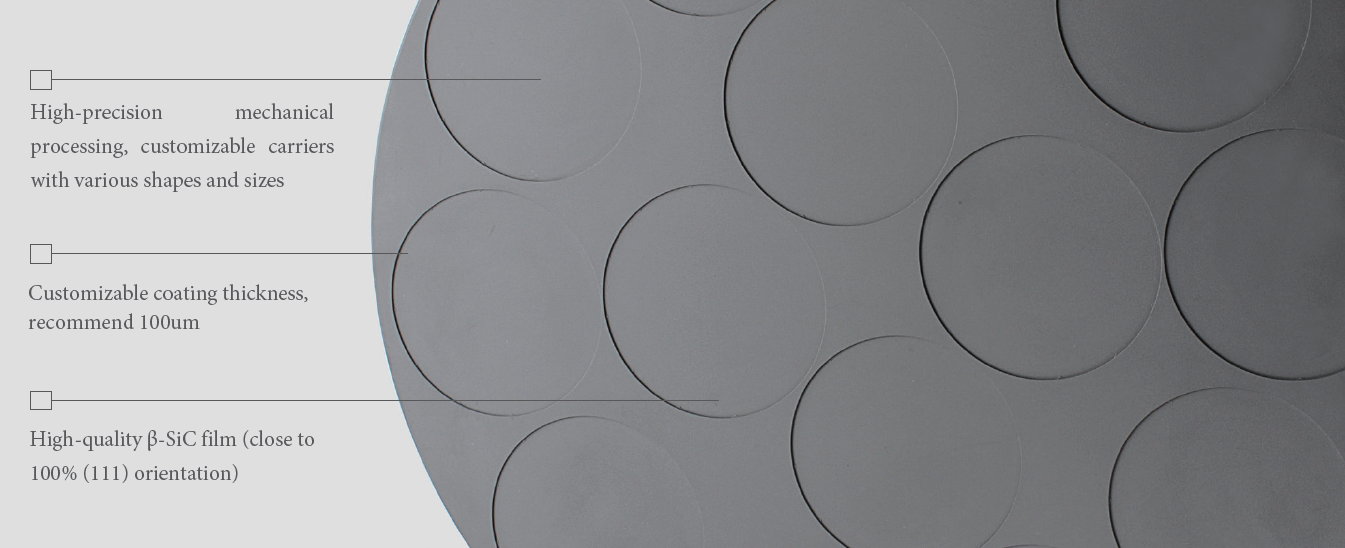

SiC Carrier for ICP

Semicorex SiC Carrier for ICP is a high-performance wafer holder made of SiC-coated graphite, designed specifically for use in inductively coupled plasma (ICP) etching and deposition systems. Choose Semicorex for our world-leading anisotropic graphite quality, precision small-batch manufacturing, and uncompromising commitment to purity, consistency, and process performance.*

Send Inquiry

Engineered to meet the uncompromising demands of modern Inductively Coupled Plasma (ICP) etch and deposition tools, Semicorex SiC‑Coated Graphite Carrier for ICP delivers a rare balance of plasma resilience, thermal precision and mechanical stability. At its core lies a proprietary, small‑batch graphite substrate whose crystal orientation is tightly controlled to produce extraordinary anisotropic behavior: in‑plane thermal conductivity far surpasses conventional isostatic grades, while the through‑plane path remains deliberately moderated to suppress wafer‑side hot spots. This directional heat‑flow management ensures that every die across a 150 mm to 300 mm wafer experiences uniform temperature ramping and steady‑state equilibrium, directly translating into narrower critical‑dimension (CD) distributions and higher device yields.

Wrapped around this ultra‑pure graphite is a conformal silicon‑carbide layer co‑deposited in a high‑temperature CVD furnace. The SiC coating—chemically inert up to 2,000 °C and boasting a micro‑porosity of less than 0.1 %—forms an impermeable shield against fluorine, chlorine and bromine radicals common in high‑density ICP chemistries. Long‑duration endurance testing in CF₄/O₂, Cl₂/BCl₃ and HBr/He plasmas has demonstrated erosion rates below 0.3 µm per 100 hours, extending carrier service life well beyond industry norms and drastically reducing preventative‑maintenance downtime.

Dimensional precision is equally uncompromised: surface flatness is controlled within ±5 µm across the entire pocketed area, while edge exclusion features are laser‑machined to protect the wafer perimeter from micro‑arcing. Tight tolerance, coupled with the SiC coating’s near‑diamond hardness, resists particle generation under mechanical clamping and electrostatic‑chuck cycling, safeguarding sub‑10 nm node processes from killer defect contamination. For high‑power ICP reactors, the carrier’s low electrical resistivity (<40 µΩ·m) promotes rapid RF ground‑plane stabilization, minimizing sheath‑voltage fluctuations that can otherwise erode photoresist profiles or induce micro‑masking.

Every batch of Semicorex carriers undergoes comprehensive metrology—Raman mapping to verify graphite crystallographic alignment, SEM cross‑sectioning to confirm SiC layer integrity, and residual‑gas analysis to certify ppm‑level impurity thresholds. Because we insist on micro‑lot production (fewer than 20 pieces per run), statistical process control charts remain exceptionally tight, allowing us to guarantee wafer‑to‑wafer reproducibility that mass‑market suppliers simply cannot match. Custom geometries, pocket depths and backside cooling channels are available with lead times as short as three weeks, empowering equipment OEMs and high‑mix fabs to optimize chamber recipes without redesigning entire hardware stacks.

By uniting world‑class anisotropic graphite with a hermetic SiC armor, the Semicorex SiC Carrier for ICP provides fabs with a long‑lived, contamination‑averse and thermally uniform platform—one that not only withstands the harshest plasma environments, but actively enhances process window latitude and die‑level performance. For device manufacturers striving toward ever‑tighter linewidths, steeper profiles and lower cost of ownership, it is the carrier of choice where every micron, every wafer and every hour of uptime counts.