- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramic Manufacturers, Suppliers, Factory

Semicorex is your partner for improving in semiconductor processing. Our silicon carbide coatings are dense, high temperature and chemical resistant, which are often used in the whole cycle of semiconductor manufacturing, including semiconductor wafer & wafer processing and semiconductor fabrication.

High-purity SiC ceramic components are crucial to processes in the semiconductor. Our offering ranges from consumables parts for wafer processing equipment, such as Silicon Carbide wafer boat, cantilever paddles, tubes, etc for Epitaxy or MOCVD.

![]()

Advantages for semiconductor processes

The thin film deposition phases such as epitaxy or MOCVD, or wafer handling processing such as etching or ion implant must endure high temperatures and harsh chemical cleaning. Semicorex supplies high-purity silicon carbide (SiC) construction provides superior heat resistance and durable chemical resistance, even thermal uniformity for consistent epi layer thickness and resistance.

Chamber Lids →

Chamber Lids used in crystal growth and wafer handling processing must endure high temperatures and harsh chemical cleaning.

Cantilever Paddle →

Cantilever Paddle is a crucial component used in semiconductor manufacturing processes, particularly in diffusion or LPCVD furnaces during processes like diffusion and RTP.

Process Tube →

Process Tube is a crucial component, specifically designed in various semiconductor processing applications such as RTP, diffusion.

Wafer Boats →

Wafer Boat is used in semiconductor processing, it has been meticulously designed to ensure the delicate wafers are kept safe during the critical stages of production.

Inlet Rings →

SiC coated gas inlet ring by MOCVD equipment Compound growth has high heat and corrosion resistance, which has great stability in extreme environment.

Focus Ring →

Semicorex supplies Silicon Carbide Coated focus ring is really stable for RTA, RTP or harsh chemical cleaning.

Wafer Chuck →

Semicorex ultra-flat ceramic vacuum wafer chucks is high purity SiC coated using in the wafer handling process.

Semicorex also have ceramic products in Alumina (Al2O3), Silicon Nitride (Si3N4), Aluminum Nitride (AIN), Zirconia (ZrO2), Composite Ceramic, etc.

- View as

SSIC Bushings

Semicorex SSIC bushings are the precision manufactured ceramic sleeve, which are specially engineered for demanding industrial systems. With excellent manufacturing technology, precise engineering design, and thoughtfully customized services, Semicorex, backed by deep expertise in the advanced SiC manufacturing industry, looks forward to becoming your long-term trusted supplier of ceramic components.

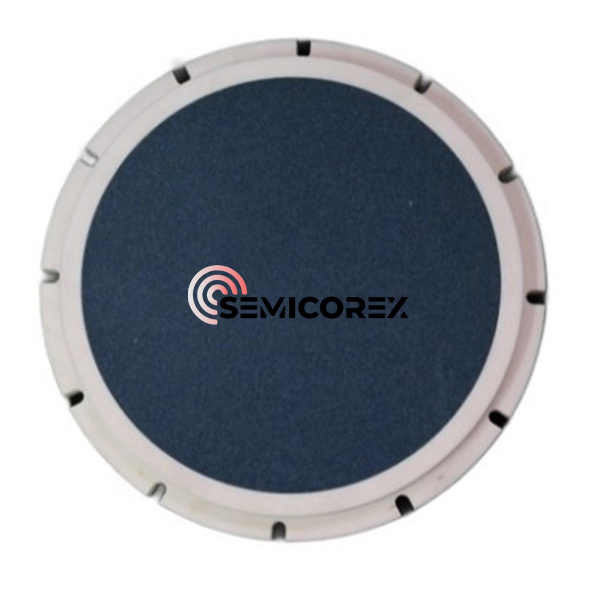

Read MoreSend InquiryMicroporous SiC Chucks

Semicorex Microporous SiC Chucks are high-precision vacuum chucking solutions, they are engineered from high-purity silicon carbide to deliver uniform adsorption, exceptional stability, and contamination-free wafer handling for advanced semiconductor processes. Semicorex is dedicated to material excellence, precision manufacturing, and reliable performance according to customers’ needs.*

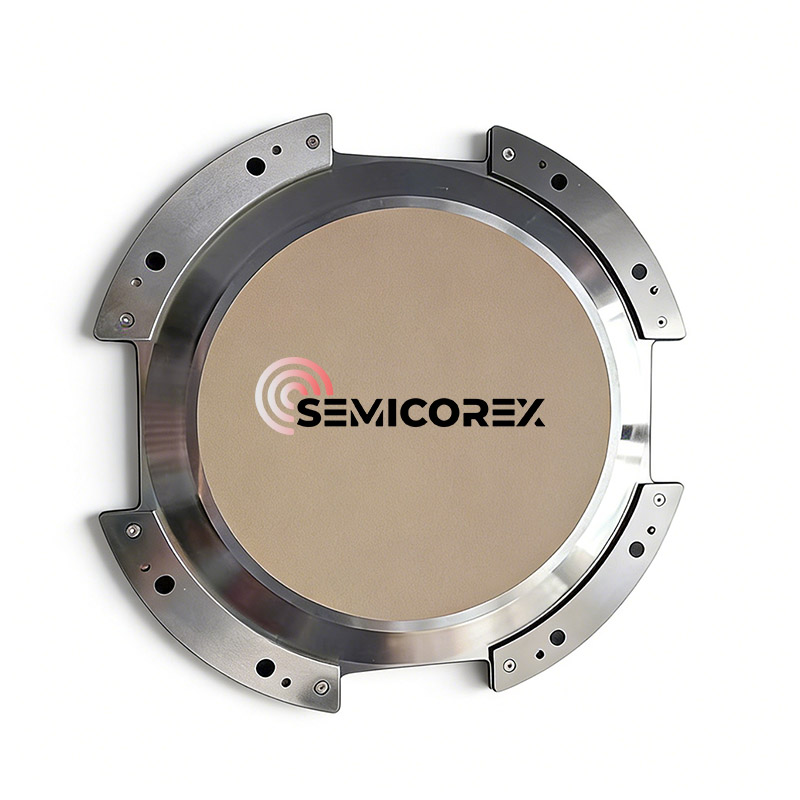

Read MoreSend InquiryMicroporous Ceramic Chuck

Semicorex microporous ceramic chuck is engineered to provide uniform, stable vacuum holding for precision manufacturing processes where flatness, cleanliness, and repeatability are critical. Designed for OEM integration, Semicorex leverages advanced ceramic materials and controlled microporous structures to deliver reliable chucking performance across demanding industrial applications.*

Read MoreSend InquiryPorous Alumina Vacuum Chuck

Semicorex Porous Alumina Vacuum Chuck leverages advanced material science to ensure uniform suction and zero-damage handling across the most demanding semiconductor fabrication processes. As a leading provider of high-performance ceramic solutions, Semicorex specializes in engineering premium Porous Alumina Vacuum Chucks that set the industry standard for wafer stability and precision.*

Read MoreSend InquiryCeramic Seals

Semicorex ceramic seals are engineered for OEM manufacturers seeking reliable sealing performance in high-wear, high-temperature, and chemically demanding industrial environments. Leveraging advanced ceramic materials and precision manufacturing, Semicorex delivers consistent, application-ready sealing solutions designed for long-term integration into industrial equipment platforms.*

Read MoreSend InquirySilicon Carbide Ceramic Sleeve

Semicorex Silicon Carbide Ceramic Sleeve is a high-performance mechanical sealing component designed to serve as the hard ring in demanding seal systems, offering exceptional wear resistance, thermal stability, and corrosion protection under extreme operating conditions. Choosing Semicorex means relying on high-purity SiC materials, advanced ceramic manufacturing and finishing capabilities, and proven expertise in delivering reliable sealing components for harsh industrial environments.*

Read MoreSend Inquiry