- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China C/C Composite Manufacturers, Suppliers, Factory

C/C composites possess high mechanical strength and excellent wear resistance. Their tensile strength ranges from 100 to 300 MPa. While lower than the 400 to 800 MPa of carbon steel, it surpasses most plastics and graphite by tens of MPa. Their flexural strength is approximately 150 MPa, three to four times that of common graphite. Their high surface hardness also provides excellent wear and impact resistance. Furthermore, they possess high toughness, resist cracking, and possess excellent chemical resistance, resisting corrosion from acids, alkalis, and organic solvents.

C/C composites are particularly renowned for their excellent physical properties and dimensional stability at high temperatures, making them a heat-resistant material. Even at temperatures exceeding 1000°C (and up to 2000°C in an inert gas atmosphere), their tensile strength and elongation remain stable, with virtually no deformation. Comparing the tensile strength of C/C composites with that of heat-resistant steel expected to be used above 400°C, while the heat-resistant steel's value is over five times that of the C/C composite at room temperature, the strength of the heat-resistant steel drops sharply above 800°C, falling below that of the C/C composite. A characteristic of C/C composites is their ability to maintain dimensional and physical properties from room temperature to high temperatures.

C/C composites are primarily used in the crystal growth process in semiconductors.

- View as

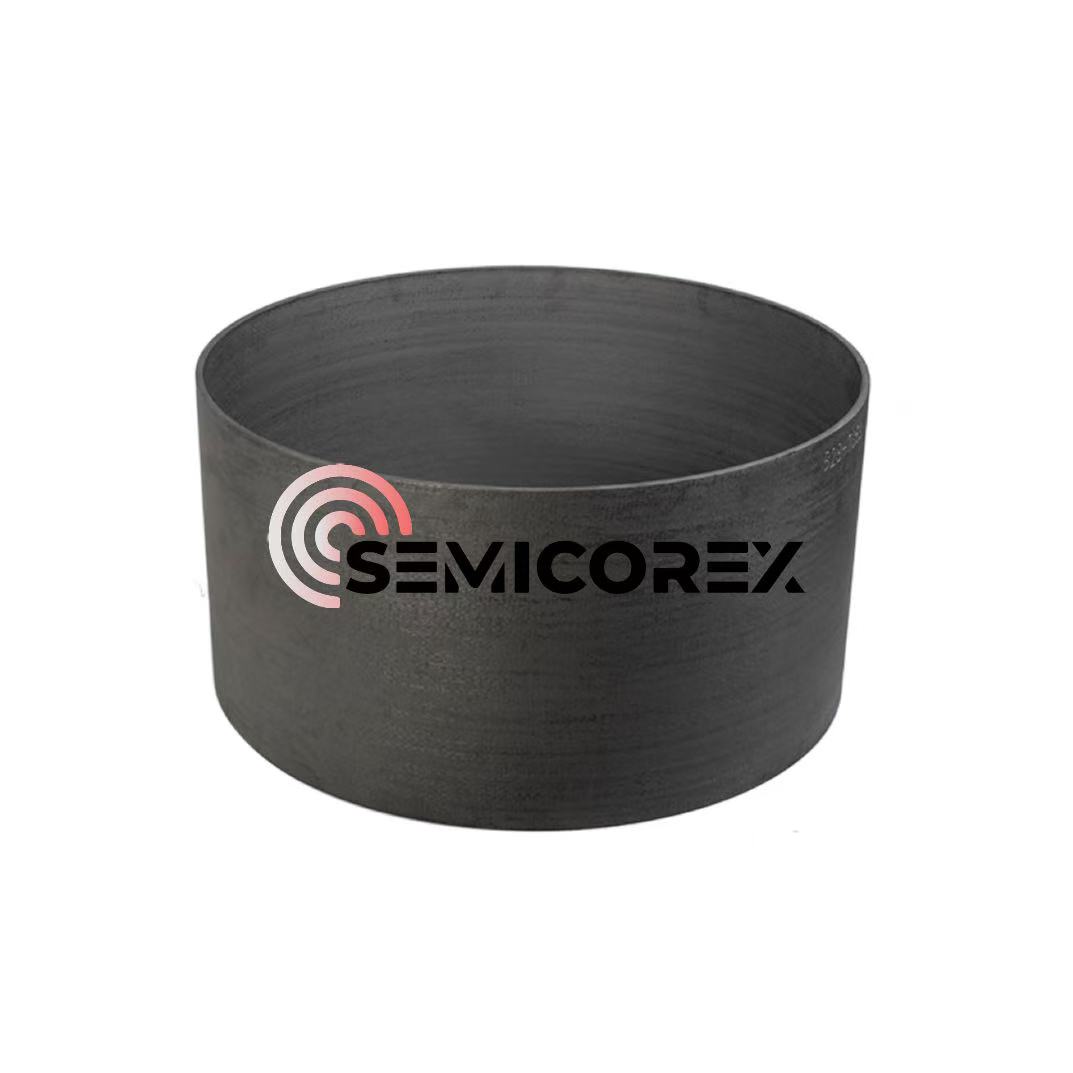

C/C Thermal Insulation Cylinders

C/C thermal insulation cylinders are the high-performing thermal insulation components used in the thermal field system for single-crystal silicon growth, serving both thermal insulation and support functions. With exceptional thermal insulation performance, excellent structural strength, and competitive price, Semicorex C/C thermal insulation cylinders stand as the ideal option for your high-quality crystal growth processes.

Read MoreSend InquiryC/C composite Heaters

C/C composite heaters are advanced heating components made from high-performance carbon-carbon composites, specifically designed for use in the high temperature furnaces. Serving as the crucial parts in the semiconductor industry, C/C composite heaters can offer precise, uniform heating necessary for optimal crystal growth conditions.

Read MoreSend InquiryC/C Composite Crucible Holders

Semicorex C/C composite crucible holders are the precision-manufactured carbon-carbon composite components, which are specifically tailored to meet the rigorous demands of high-temperature conditions. They are typically positioned at the bottom of the crucible, and are dependable support solutions for stabilizing crucible in the high-temperature crystal growth furnaces.

Read MoreSend InquiryCarbon-carbon Composite Flow Guides

Carbon-carbon composite flow guides are the advanced cylindrical semiconductor components, serving as the brilliant solutions to guarantee the successful fabrication of single-crystal silicon in high-temperature pulling systems. They can serve both as gas flow directors and thermal insulators during high temperature single-crystal silicon production.

Read MoreSend InquiryAircraft Brakes disc

Semicorex Aircraft Brakes Disc is made of carbon-carbon composites, can withstand high temperature when heavy braking of aircraft, also with good performance of wear level. Semicorex is committed to deliver the high-quality products to worldwide.*

Read MoreSend InquiryC/C Composite Fasteners

Semicorex's C/C composite fasteners made from high-performance carbon-carbon composite materials, which undergo precision machining to meet strict standards, all designed specifically for extreme high-temperature conditions. What makes these C/C composite fasteners stand out is their combination of low density, outstanding high-temperature resistance, superior thermal stability, and exceptional chemical resistance. These qualities together deliver a fastening solution that’s safe, dependable, and long-lasting, perfectly suited for high-end equipment.

Read MoreSend Inquiry