- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

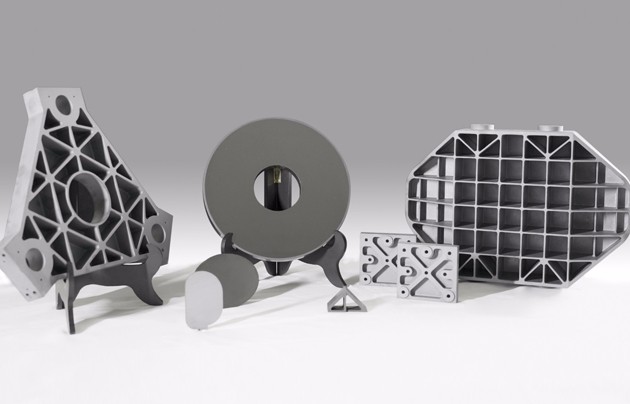

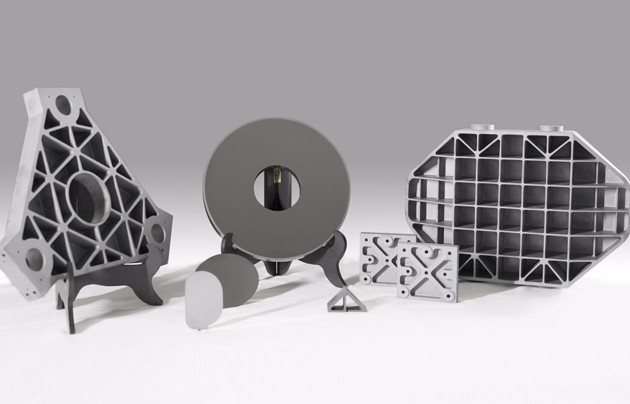

SiC Mirrors

Semicorex SiC Mirrors are high-performance silicon carbide optical components engineered for extreme precision in applications such as optic scan systems, lithography, and space-based telescopes. Choose Semicorex for our advanced manufacturing expertise, customizable designs, and exceptional surface finishing that ensure unmatched stability, reflectivity, and reliability in the most demanding environments.*

Send Inquiry

Semicorex SiC Mirrors are top-tier optical components for demanding situations that benefit from great mechanical stability, high thermal conductivity, and high surface quality. The mirrors are manufactured from high purity silicon carbide, which combines advantages of low density, high stiffness, and advantageous superior thermal stability, which makes it the right choice for cutting-edge optical systems when a reliable platform is a necessity in rugged applications. SiC Mirrors achieve optical performance during extreme thermal and mechanical stress which is important in precision optics or scanning applications to provide consistent and accurate imaging or scanning results.

One of the more common applications of SiC Mirrors is in optical scan systems where the fast movement and accurate beam positioning require mirrors designed with low deformation and good dimensional stability. The structure of SiC Mirrors achieves low mass with high rigidity and allows for rapid scanning with no loss of image quality or alignment accuracy. SiC Mirrors are forecasted to be equally important in lithography systems with nanometer accuracies in the semiconductor manufacturing process. The SiC material’s low coefficient of thermal expansion contributes to constancy in the mirror's surface figure, with temperature fluctuations in the environment impacting the stability of their shape. Thus allowing for a superior pattern fidelity in ultraviolet exposure of a wafer.

Silicon carbide (SiC) mirrors have become the material of choice for space-based telescopes and astronomical instruments for large aperture optical systems. The lightweight characteristics of SiC allow for lighter weight optical systems and, consequently, lower launch costs and a lower structural load on the spacecraft. In addition, silicon carbide has inherent thermal conductivity that minimizes thermal gradients across its surface, which helps retain diffraction limited performance amid extreme temperature variations and a vacuum in the condition of space. The mechanical durability of SiC mirrors ensures that the mirror will maintain structural integrity under large launch loads and significant time period missions, regardless of the mission's duration.

However, in order to promote even further optical performance, the SiC mirrors can have surface coatings altered by the using of several different coating methodologies, depending on the intended optical application or environment. Both CVD SiC coatings can provide an ultra-smooth, high purity surface ideal for polishing into the high-reflectivity optical finish, and polished silicon coatings can achieve extremely low surface roughness for use in the visible or near-infrared. All coatings enhance the reflectivity and surface quality of the SiC mirrors substrate and act as an environmental barrier to improve durability against environmental degradation and contribute to stability of optical performance.

The manufacturing process for SiC Mirrors allows for a high degree of flexibility in both shape and structural features to meet precise optical design needs. We deliver flat mirrors for highly accurate beam steering, spherical mirrors for imaging and focusing reflectors, and aspherical mirrors for an optical system that may need to address spherical aberrations and accurate images. Additionally, we can include complex lightweighting designs in the mirror substrate itself, which adds further mass reduction without impacting stiffness - very advantageous features for space systems and scanning systems.

Every SiC Mirror is fabricated and polished to the required optical figure, which included, as a quality control step, measurement of surface roughness. Metrology and measurement processes are used throughout the work to verify compliance with optical tolerances, while quality control processes ensure the mirror has the necessary mechanical and thermal and optical performance for the application. We will engineer and build to your custom unique designs and standards in all applications (cleanroom semiconductors to outer space).

With their unique properties of low weight, high stiffness, substantial thermal conductivity and the ability of respond to custom designs, SiC Mirrors are a platform ideally suited for future optical systems. Whether used in high-speed scanning, nanometer-precision lithography, or large-aperture space telescopes, these mirrors deliver unmatched performance and durability, enabling optical engineers to push the boundaries of imaging and beam control technology.