- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

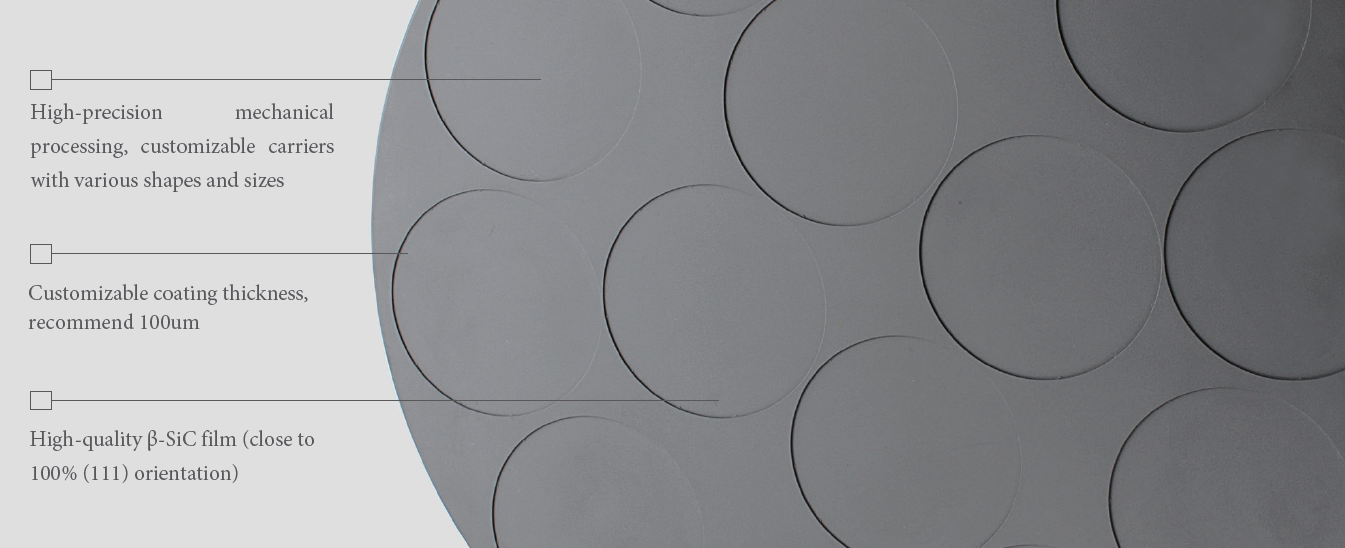

SiC Coated Plate

Semicorex SiC Coated Plate is a precision-engineered component made from graphite with a high-purity silicon carbide coating, designed for demanding epitaxial applications. Choose Semicorex for its industry-leading CVD coating technology, strict quality control, and proven reliability in semiconductor manufacturing environments.*

Send Inquiry

Semicorex SiC Coated Plate is an engineered high-performance component specifically designed for epitaxial (epi) growth equipment, requiring stable, high-purity substrates to create high-quality films. It is a high-strength graphite core, uniformly and densely coated with silicon carbide (SiC), achieving the unparalleled thermal and mechanical resistivity of high-strength graphite combined with the chemical stability and surface durability of SiC. The Semicorex SiC Coated Plate is built to sustain the extreme rigors of the epitaxial processes for compound semiconductors including SiC and GaN.

The graphite core of the SiC Coated Plate possesses outstanding thermal conductivity, low density, and superior thermal shock resistance. The moderately low thermal mass of the graphite core balanced with excellent thermal conductivity allow for a rapid distribution of heat evenly in a process where temperature cycles take place at high speeds. The outer layer of SiC deposited by chemical vapor deposition (CVD), offers a protective barrier that increases hardness, corrosion resistance, and chemical inertness, offering immediate value in limiting or preventing particle generation. This solid elemental surface combined with the physical characteristics of the graphite base, assure a very high purity process environment with very little or no risk of defect generation on the epitaxial layers.

Dimensional precision and surface flatness are also essential attributes of the SiC Coated Plate. Each plate is machined and coated with tight tolerances in order to ensure uniformity and repeatability in process performance. The smooth and inert surface reduces nucleation sites for unwanted film deposition and improves wafer uniformity across the plate surface.

In epitaxial reactors, the SiC Coated Plate is typically implemented as a susceptor, liner, or a thermal shield to give structure and perform as a heat transfer medium to the wafer being processed. Stable performance will directly affect crystal quality, yield, and productivity.