- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Graphite Carrier for Epitaxial Reactors

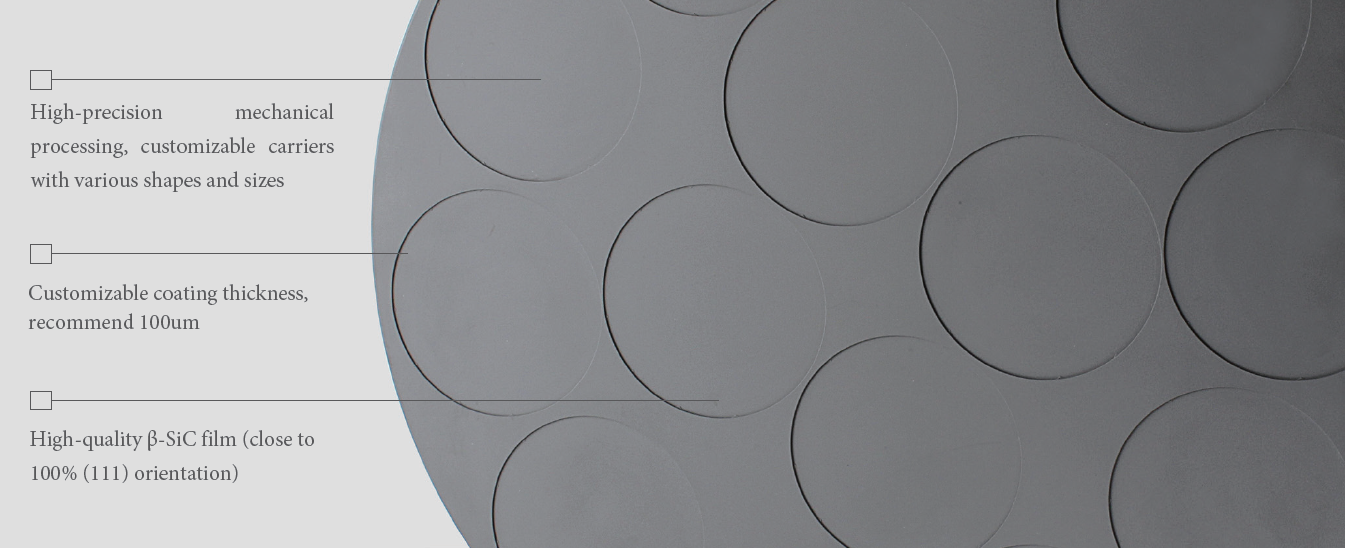

Semicorex Graphite Carrier for Epitaxial Reactors is a SiC coated graphite component with precision micro-holes for gas flow, optimized for high-performance epitaxial deposition. Choose Semicorex for superior coating technology, customization flexibility, and industry-trusted quality.*

Send Inquiry

Semicorex Graphite Carrier for Epitaxial Reactors is an engineered component for epitaxial deposition for semiconductor manufacturing. This graphite carrier is made of high purity graphite and coated uniformly with SiC. This carrier comes with several advantages reducing responsibility, wear & tear, and providing better chemical stability when in corrosive environments and also in high temperatures. The bottomıyla dense micro porosity on the bottom surface provides uniform gas distributions across the wafer surface during growth that must be exact enough to produce defect free crystals layers.

The SiC coated carrier is focussed on horizontal or vertical epitaxial reactors, whether batch or single wafer. The silicon carbide coating protects the graphite, names ed improves etching resistance, is oxidation resistant, and also the thermal shock compared to uncoated graphite revolutionising the approach operators have to/invested using monumental time wasted making extensive maintenance/replacing with carrier with less intervening service life on every phase of thermal cycle; hastening the maintenanceinfo from the bucket or downed rk reputable polymers able with the carrier with maybe be replaced once as everything else ; to maximize operational efficacies instead prenatal or per scheduled maintenance.

The base graphite substrate is fabricated from ultra-fine grain, high-density material, providing built-in mechanical stability and dimensional stability under extreme thermal loading. A fixed, precise SiC coating can be added to the carbon layer utilizing chemical vapor deposition (CVD), which together provides a high density, smooth, sharp, and pinhole free layer with a strong surface bond. This can mean good compatibility with process gases and reactor condition, as well as reduced contamination and fewer particles that can effect wafer yield.

The micro-hole location, spacing, and structure on the bottom of the carrier is planned to promote the most efficient and uniform gas flow from the base of the reactor through the perforations of the graphite carrier to the wafers above it. A uniform gas flow from the base of the reactor can significantly change process control of layer thickness and doping profiles in graphite carriers for epitaxial growth processes, especially in gaseous compound semiconductors like SiC or GaN where precision and repeatability is crucial. Furthermore, the specification of perforation density and pattern is highly customizable, defined by the reactor design of each corporation, and perforation structure is based on the process specifications.

Semicorex graphite carriers are designed and manufactured with the rigors of the epitaxial process environment in mind. Semicorex offers customization for all sizes, hole patterns, and coated thicknesses to integrate seamlessly into your existing equipment. Our in-house ability to manufacture carriers, and exacting quality control ensure accurate, repeatable performance, high purity solutions, and reliability that is demanded by today's leading semiconductor manufacturers.