- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China wafer boat Manufacturers, Suppliers, Factory

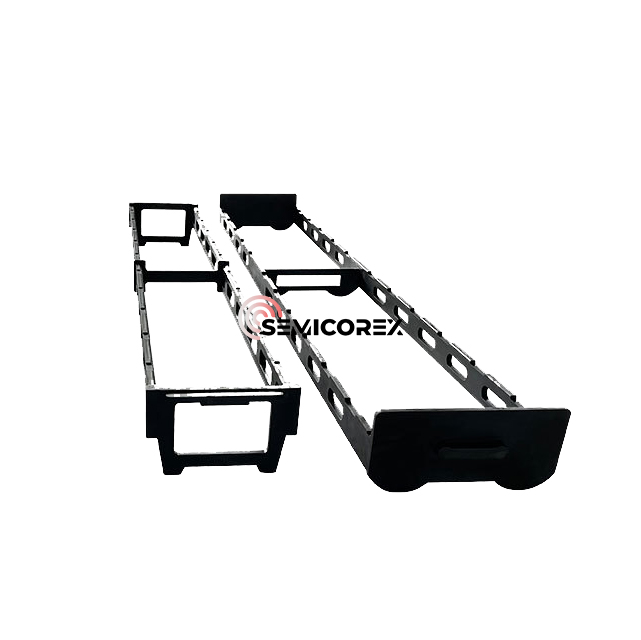

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for wafer boat,silicon carbide,Wafer carrier,Silicon Carbide Boat,sintered silicon carbide, We adhere towards the tenet of "Services of Standardization, to fulfill Customers' Demands".

wafer boat, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to give our best service to satisfy all your needs! Remember to contact us right away!

Hot Products

ICP Silicon Carbon Coated Graphite

Semicorex's ICP Silicon Carbon Coated Graphite is the ideal choice for demanding wafer handling and thin film deposition processes. Our product boasts superior heat and corrosion resistance, even thermal uniformity, and optimal laminar gas flow patterns.SiC Coated MOCVD Susceptor

Semicorex is a leading manufacturer and supplier of SiC Coated MOCVD Susceptor. Our product is specially designed for semiconductor industries to grow the epitaxial layer on the wafer chip. The high purity Silicon Carbide coated graphite carrier is used as the center plate in MOCVD, with a gear or ring-shaped design. Our susceptor is widely used in MOCVD equipment, ensuring high heat and corrosion resistance, and great stability in extreme environments.SiC Coating Graphite Substrate Wafer Carriers for MOCVD

You can rest assured to buy SiC Coating Graphite Substrate Wafer Carriers for MOCVD from our factory. At Semicorex, we are a large-scale manufacturer and supplier of SiC Coated Graphite Susceptor in China. Our product has a good price advantage and covers many of the European and American markets. We strive to provide our customers with high-quality products that meet their specific requirements. Our SiC Coating Graphite Substrate Wafer Carrier for MOCVD is an excellent choice for those looking for a high-performance carrier for their semiconductor manufacturing process.Spare Parts in Epitaxial Growth

Semicorex Spare Parts in Epitaxial Growth are crucial components utilized within epitaxial growth systems, particularly in processes involving quartz tube setups. These parts play a vital role in facilitating gas flow to drive tray base rotation and ensure precise temperature control throughout the epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.TaC Coating Half-moon

Semicorex TaC Coating Half-moon is a specialized component crafted from tantalum carbide (TaC) coated graphite, designed for use in epitaxial processes. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.TaC Coated Ring

Semicorex TaC Coated Ring stands as a critical component that meets these demanding requirements. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China*.

Related Search

Aluminum Oxide Wafer BoatCVD Sic Wafer BoatsGraphite Wafer BoatHigh-Temperature Wafer BoatHorizontal quartz wafer boats manufacturerQuartz Wafer BoatQuartz wafer boatssemiconductor wafer boatSemiconductor Wafer Boat HolderSemiconductor Wafer Boatssic boat;wafer diffusion;RBSiC;SSiC;diffusion furnace semiconductor;wafer boat;wafer carrier;annealing in semiconductor fabrication;photovoltaic;CVD SiCSic Coated Wafer BoatsSiC;wafer boatSilicon Carbide Coated Ceramic Wafer Boatssilicon horizontal wafer boatsWafer Boat HolderWafer Boat RackWafer Boat Storagewafer boat towwafer boat;wafer diffusion;horizontal diffusion furnace;;RBSiC;SSiC;sic ceramic;silicon carbide company;cvd sic process;wafer carrier;wafer boats