- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China sic boat;wafer diffusion;RBSiC;SSiC;diffusion furnace semiconductor;wafer boat;wafer carrier;annealing in semiconductor fabrication;photovoltaic;CVD SiC Manufacturers, Suppliers, Factory

With superior technologies and facilities, strict quality command, reasonable cost, exceptional provider and close co-operation with customers, we've been devoted to delivering the best benefit for our buyers for sic boat;wafer diffusion;RBSiC;SSiC;diffusion furnace semiconductor;wafer boat;wafer carrier;annealing in semiconductor fabrication;photovoltaic;CVD SiC, We sincerely welcome friends to barter business enterprise and start cooperation with us. We hope to hitch hands with close friends in different industries to produce a brilliant long run.

sic boat;wafer diffusion;RBSiC;SSiC;diffusion furnace semiconductor;wafer boat;wafer carrier;annealing in semiconductor fabrication;photovoltaic;CVD SiC, With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Hot Products

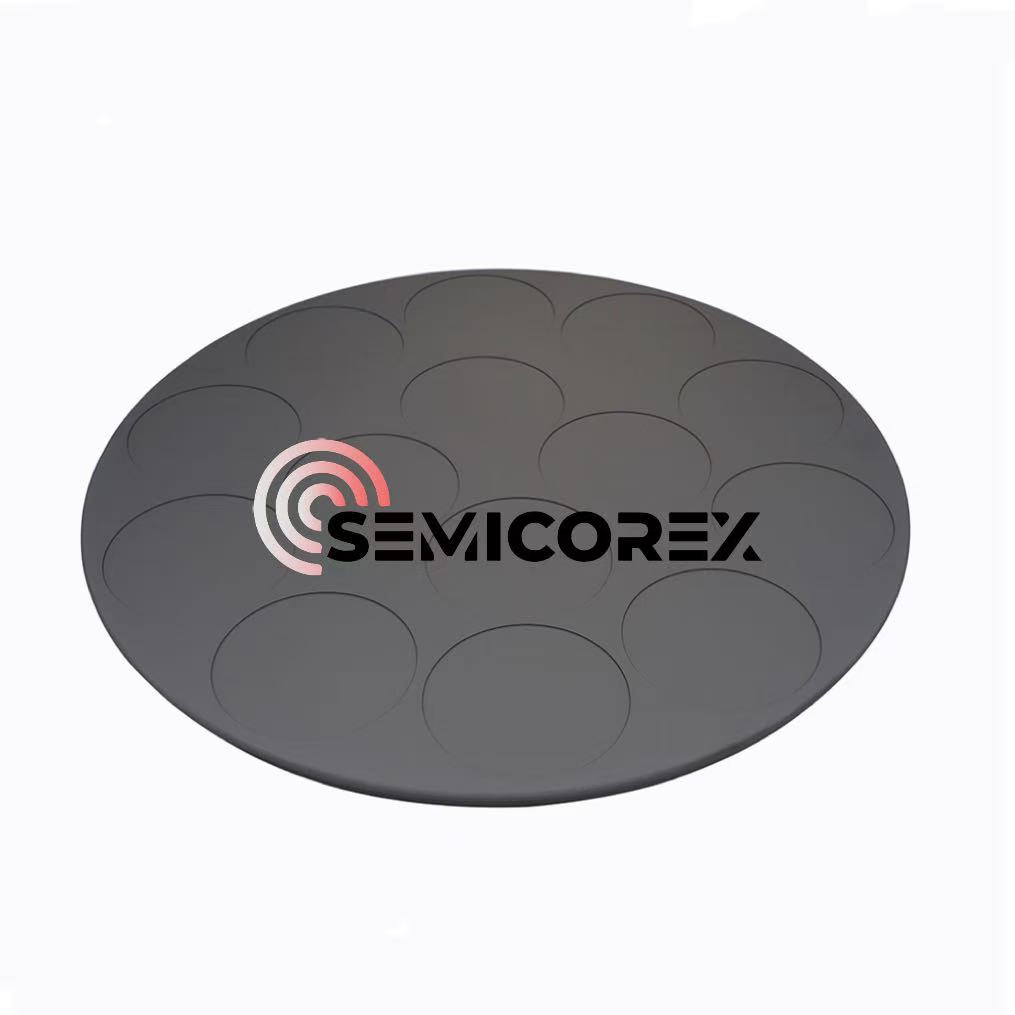

Barrel Susceptor with SiC Coating in Semiconductor

If you're looking for a high-quality graphite susceptor coated with high-purity SiC, the Semicorex Barrel Susceptor with SiC Coating in Semiconductor is the perfect choice. Its exceptional thermal conductivity and heat distribution properties make it ideal for use in semiconductor manufacturing applications.Silicon Carbide Graphite Substrate MOCVD Susceptor

Semicorex Silicon Carbide Graphite Substrate MOCVD Susceptor is the ultimate choice for semiconductor manufacturers looking for a high-quality carrier that can deliver superior performance and durability. Its advanced material ensures even thermal profile and laminar gas flow pattern, delivering high-quality wafers.TaC Coated Graphite Susceptor

Semicorex cutting-edge TaC Coated Graphite Susceptor, a revolutionary component designed to elevate your wafer epitaxial process to new heights of efficiency and precision. Crafted with unparalleled expertise and utilizing state-of-the-art technology, Semicorex TaC Coated Graphite Susceptor is engineered to meet the exacting demands of semiconductor manufacturing.Ring Set

Unlock the full potential of your semiconductor epitaxial processes with Semicorex Ring Set – a crucial component crafted from SiC-coated graphite. Designed to elevate the efficiency and reliability of your epitaxial growth, this small yet powerful accessory plays a key role in ensuring optimal performance within semiconductor manufacturing environments.Single-crystal Silicon Epi Susceptor

The Single-crystal Silicon Epi Susceptor is an essential component designed for Si-GaN epitaxy processes, which can be tailored to individualized specifications and preferences, providing a bespoke solution that aligns perfectly with specific requirements. Whether it entails modifications in dimensions or adjustments in coating thickness, we possess the capability to design and deliver a product that accommodates diverse process parameters, thereby optimizing performance for targeted applications. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.