- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

TaC Coated Components in Epitaxial Growth

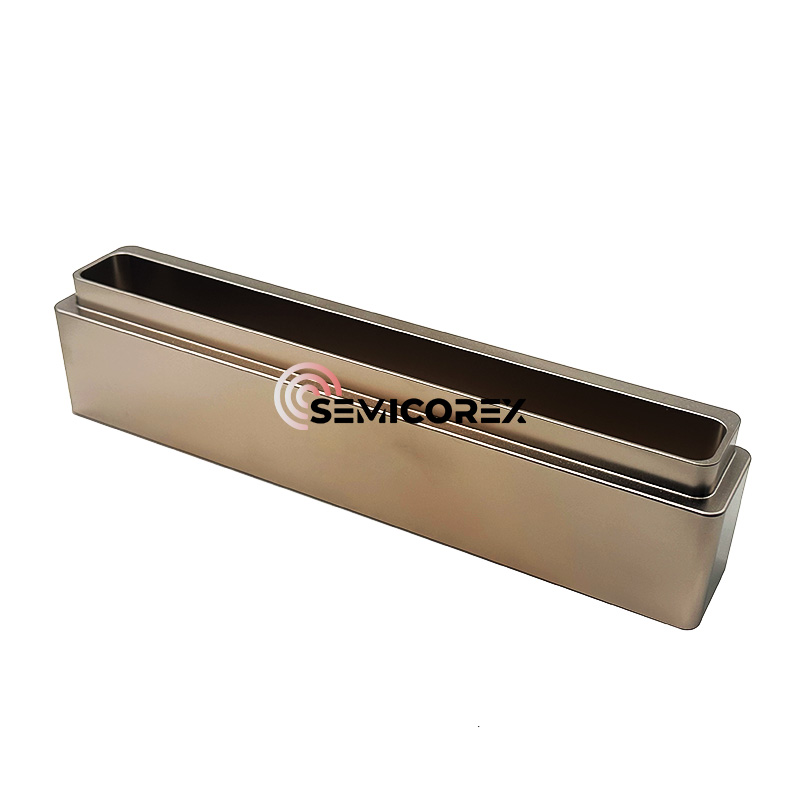

Semicorex TaC Coated Components in Epitaxial Growth is a precious machined part located in the air intake in the epitaxial process in semiconductor. Semicorex is a top-notch company that specializes in CVD TaC coating technology in China, and exports products worldwide.*

Send Inquiry

Semicorex TaC coated components in epitaxial growth is a rectangular tube-shaped part, the part is mainly responsible in air intake progress in the CVD furnace. So it is an essential component, and facing a strict environment, the temperature is high also there are corrosive gases. It brings out the reason we select the TaC coated graphite.

The Advantages of Tantalum Carbide (TaC) Coating

Tantalum Carbide (TaC) coatings are required for some of the most critical parts of the air intake systems designed for use in harsh conditions like those found inside a Chemical Vapour Deposition (CVD) furnace. The high temperature and exposure to corrosive gases found in a CVD furnace creates a very challenging working environment. With its potential to provide excellent chemical inertness and to resist corrosion and degradation, the use of TaC coatings on air intake TaC coated components in epitaxial growth will greatly reduce the potential for creating defective particles, therefore, extending the life of the component and providing the highest yield and quality of gathered epithelium films.

Coating Technology Excellence

Semicorex uses advanced CVD technology to manufacture TaC coated components in epitaxial growth to meet today's most demanding industry standards for both performance and quality. The precision with which Semicorex manufactures TaC coatings is evident through the high quality of the coatings manufactured.

|

Feature |

Semicorex Advantage |

Impact on Customer |

|

Excellent Adhesion |

Optimized deposition process creates a strong, uniform chemical bond between the TaC layer and the graphite substrate. |

No delamination or peeling under thermal cycling, ensuring long-term reliability. |

|

Surface Uniformity |

Precise control over coating thickness and homogeneity across all internal and external surfaces of the rectangular tube. |

Consistent flow dynamics and thermal performance, vital for repeatable air intake. |

|

High Coating Purity |

We use high-purity precursors and a meticulous process to achieve an exceptionally clean TaC layer. |

Minimized trace metal and impurity contamination that can affect the quality of the grown epitaxial film. |

Optimized Substrate Selection

The performance of a coated part is fundamentally tied to the quality of its substrate. The choice of the most suitable graphite base material for Semicorex's TaC-coated rectangular tubes is carefully made by our engineering team by following a number of important criteria, which are as follows:

We select a grade of graphite based on its physical properties to achieve the strongest bond between the TaC coating and the graphite substrate. This ensures that there is maximum adhesion of the TaC coating to the graphite substrate.

The graphite used to make our TaC-coated rectangular tubes must be of extremely high purity to minimize the possibility of outgassing and contamination during our high-temperature CVD process.

Our strict sourcing and quality control processes ensure that every batch of graphite substrate we use has the same material characteristics. This allows us to produce a TaC-coated rectangular tube every time, with the same performance characteristics.

Proven Reliability and Partnership

Our TaC coated components in epitaxial growth have been extensively tested and approved by many of the largest and most well-respected manufacturers in the semiconductor industry. These manufacturers have established Semicorex products as reliable standards for use in the critical applications of epitaxial growth.

We recognize that the supply of components is a significant component of your production process. That is why Semicorex has made the commitment to be a long term partner by delivering a high-quality and reliable product supply and by excelling in providing logistics and after-sales support to keep your business flowing smoothly and uninterrupted.