- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramic Manufacturers, Suppliers, Factory

- View as

Hot-pressed Boron Nitride Crucibles

Specially designed for extreme temperature applications, Hot-pressed Boron Nitride Crucibles are indispensable ceramic containers serving as the brilliant solutions both for metal melting and evaporation processes and semiconductor crystal growth processes.

Read MoreSend InquirySiC Thermocouple Protection Tubes

Manufactured by high-quality silicon carbide materials, SIC thermocouple protection tubes are advanced ceramic solutions used to protect thermocouples from operating normally in demanding high-temperature environments.Choose Semicorex for precision-engineered SIC thermocouple protection tubes that ensure consistent quality, cost-effective price, and maximized cooling efficiency.

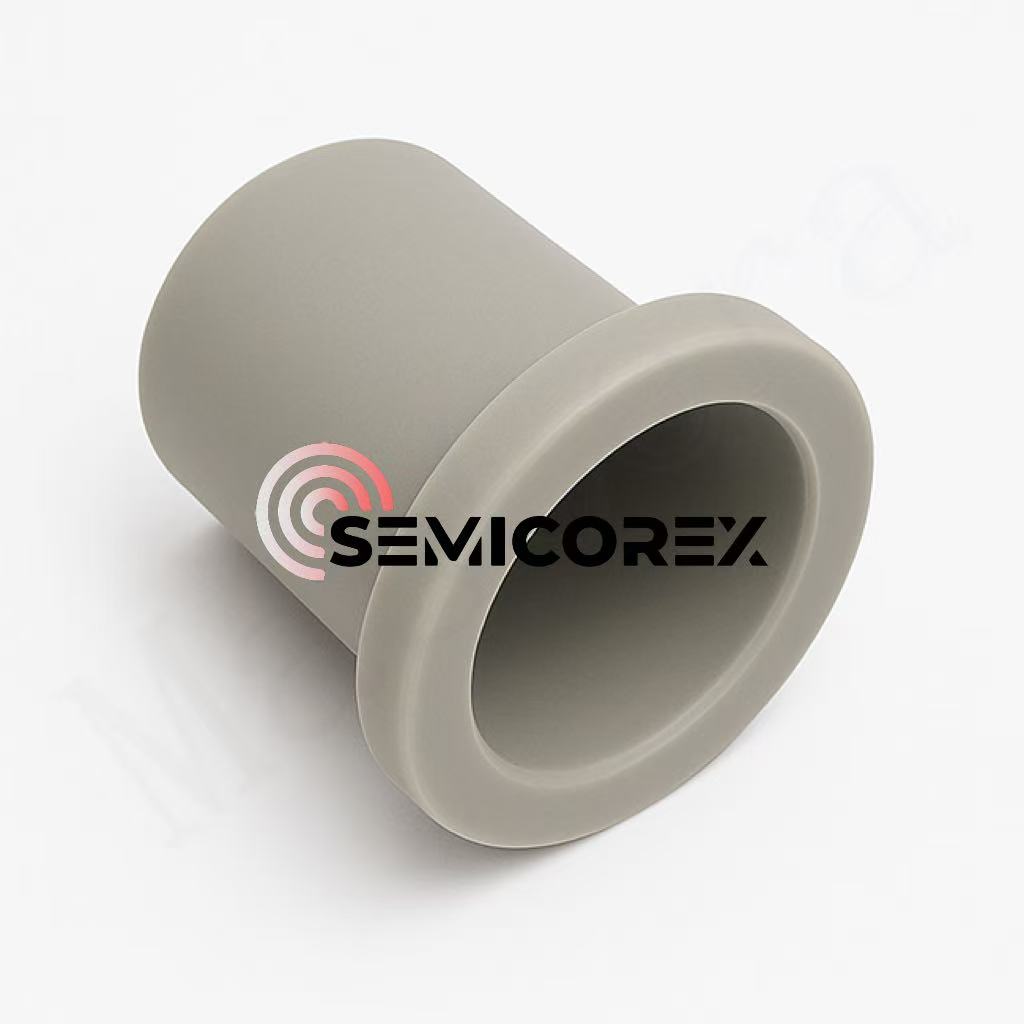

Read MoreSend InquirySilicon Carbide Cooling Ducts

Made of the high performing silicon carbide ceramic, silicon carbide cooling ducts are performant pipe components used in cooling processes of high-temperature industrial kilns. Choose Semicorex for precision-engineered Silicon carbide cooling ducts that ensure consistent quality, cost-effective price, and maximized cooling efficiency.

Read MoreSend InquiryCarbon Ceramic Brake

Semicorex Carbon Ceramic Brake is made of advanced carbon ceramic composites, which are an advanced material that is highly suitable for the high-temperature working environment. Semicorex delivers customized products according to the applications and customers’ requirements.*

Read MoreSend InquirySilicon Carbide ICP Etching Plate

Silicon Carbide ICP Etching Plate is indispensable wafer holder manufactured by high-purity sintered silicon carbide ceramic. Specially designed by Semicorex, it serves as the crucial enablers for inductively coupled plasma (ICP) etching and deposition systems in the cutting-edge semiconductor industry.

Read MoreSend InquiryAluminum Nitride Crucibles

Aluminum nitride crucibles from Semicorex are manufactured by the semiconductor-grade AlN ceramics, which are the high-performance reaction vessels applied in the challenging high-temperature environments. Semicorex offers customized production as per customer requirements, handling both large-scale orders and small-batch prototype needs.

Read MoreSend Inquiry