- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramic Manufacturers, Suppliers, Factory

- View as

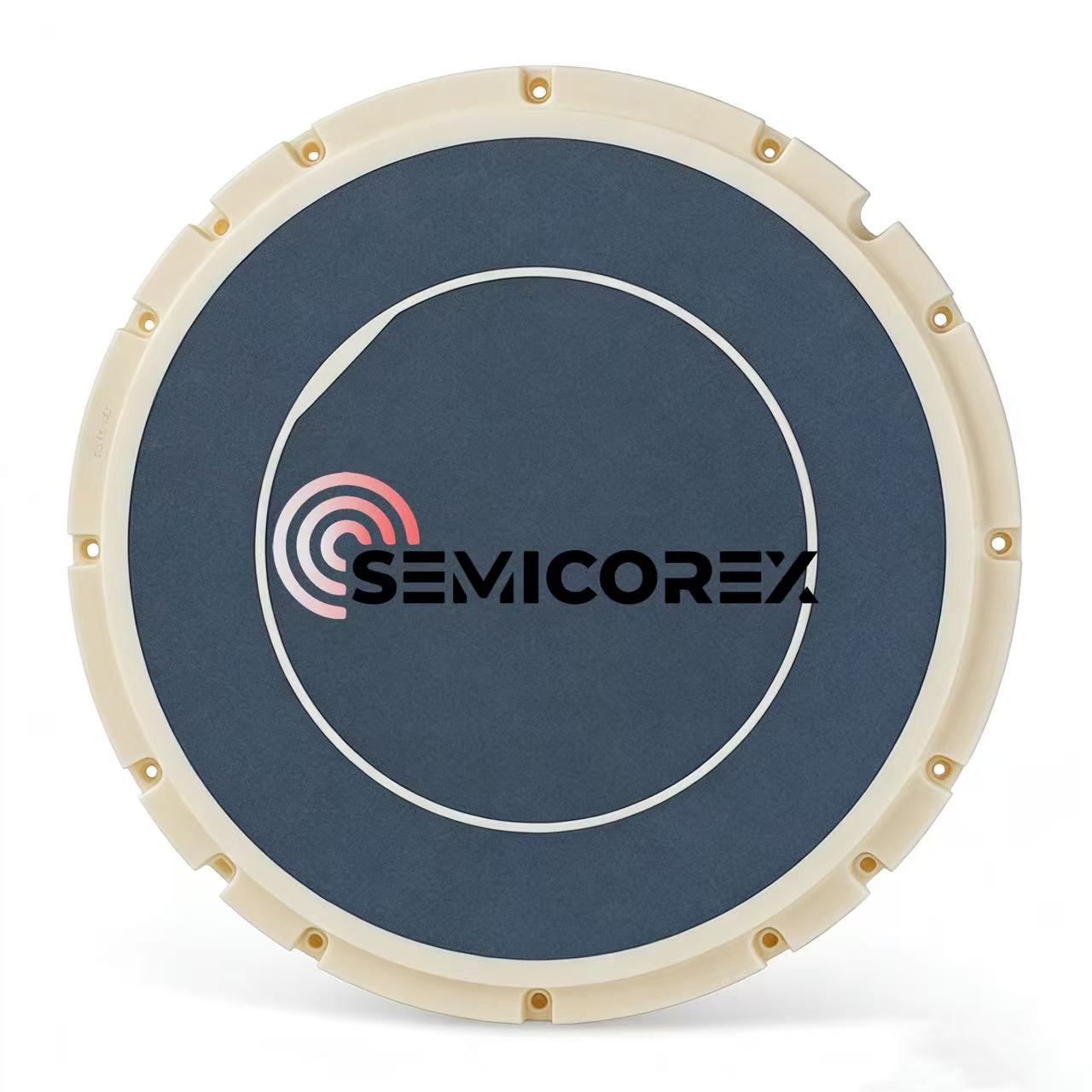

Alumina Ceramic Vacuum Chucks

Alumina ceramic vacuum chucks are the functional adsorption components, which are specially designed to clamp and fix the semiconductor wafers. Made from high-performing alumina ceramics, they deliver several excellent characteristics, such as remarkable mechanical strength, exceptional electrical insulation, and superior surface flatness.

Read MoreSend InquirySIC Horizontal Furnace Tubes

SIC horizontal furnace tubes are the horizontally placed tubular reaction and heating containers that provides the stable high-temperature processing environments for semiconductor materials. With their unparalleled material properties, precision design, and enduring service life, Semicorex's SIC horizontal furnace tubes are the optimal solutions for improving yield and product quality.

Read MoreSend InquirySiC Ceramic Robotic Arm

SiC ceramic robotic arm is the vital important silicon carbide ceramic part, which is specially designed for precisely handling and positioning semiconductor wafers. With its remarkable performance, long-lasting service life, SiC ceramic robotic arm are able to ensure the stable and effective operation in the advanced semiconductor manufacturing process.

Read MoreSend InquirySilicon Carbide Grinding Barrels

Silicon carbide grinding barrels are the advanced ceramic containers responsible for containing materials and grinding media (such as grinding beads), while achieving the refined processing of materials. Made primarily of high-performing silicon carbide, silicon carbide grinding barrels possess excellent hardness, superior wear resistance, and exceptional thermal conductivity.

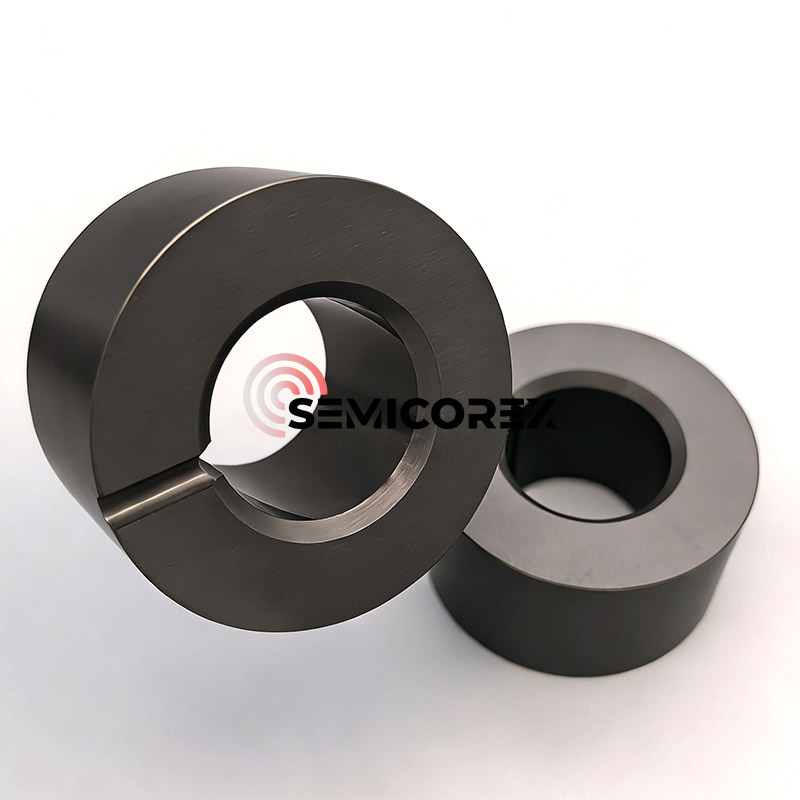

Read MoreSend InquirySiC Wear-resistant Bushing

Semicorex SiC Wear-resistant Bushing is a high-strength silicon carbide ceramic sleeve engineered for extreme durability, high-temperature stability, and long-term wear resistance in demanding industrial systems. Choosing Semicorex ensures superior material purity, precise custom machining, and consistently reliable ceramic components backed by deep expertise in advanced SiC engineering.*

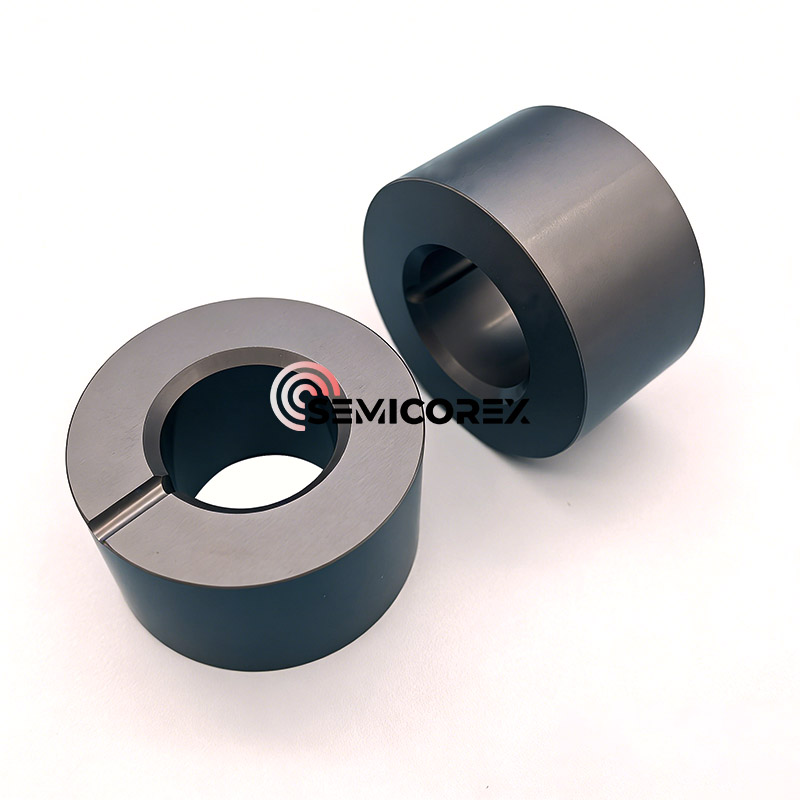

Read MoreSend InquirySiC Seal Rings

Semicorex SiC Seal Rings are made by high-quality Silicon Carbide ceramic, are suitable for wide applications in industry. Semicorex provides high precious machining ceramic products, and is looking for a long-term relationship with the customers.*

Read MoreSend Inquiry