- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Microporous SiC Chucks

Semicorex Microporous SiC Chucks are high-precision vacuum chucking solutions, they are engineered from high-purity silicon carbide to deliver uniform adsorption, exceptional stability, and contamination-free wafer handling for advanced semiconductor processes. Semicorex is dedicated to material excellence, precision manufacturing, and reliable performance according to customers’ needs.*

Send Inquiry

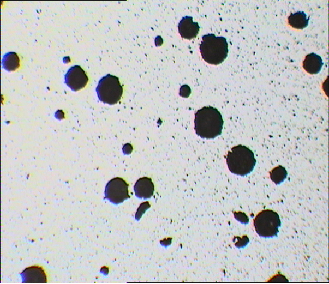

To provide superior precision and stability as well as cleanliness for advanced wafer processing, Microporous SiC Chucks are built from very high-purity silicon carbide and have a uniformly distributed microporous (or “micro-pore”) structure, resulting in a highly uniform distribution of vacuum adsorption across a fully usable chuck surface. These chucks are specifically designed to meet the rigorous demands of semiconductor manufacturing, compound semiconductor processing, microelectromechanical systems (MEMS), and other industries that require control of precision.

Excellent performance of Microporous SiC Chucks

The primary benefit of Microporous SiC Chucks is their complete integration of vacuum distribution enabled by controlling the microporous matrix within the chuck itself, as opposed to using grooves and drilled holes like traditional vacuum chucks. By using a microporous structure, the vacuum pressure is transmitted uniformly across the entire surface of the chuck, providing the needed stability and uniformity of holding force to minimize deflection, edge damage, and local stress concentration, thus helping to avoid the risks associated with thinner wafers and advanced process nodes.

The selection of SiC as a material for Microporous SiC Chucks is made because of its exceptional mechanical, thermal, and chemical characteristics. Microporous SiC Chucks are also designed to be exceptionally stiff and wear-resistant so that they will retain their dime

nsional stability even under continuous use. They have a very low coefficient of thermal expansion and very high thermal conductivity; thus, they can support tasks involving rapid changes in temperature and localized heating or plasma exposure while maintaining the flatness and positional accuracy of the wafer throughout the process cycle.

Chemical stability is an additional advantage of Semicorex Microporous SiC Chucks. One of the key advantages of silicon carbide is its ability to withstand exposure to harmful gases (including corrosive gases, acids, and alkalis) that typically exist in aggressive plasma systems used for semiconductor fabrication. The high level of chemical inertness provided by the Semicorex Microporous SiC Chucks allows for minimal surface degradation and particle generation when in contact with various processes, which enables cleanroom processing to be conducted under very tight limits of cleanliness and increases yield and process consistency.

Semicorex's design and manufacturing processes are focused on achieving the highest possible degree of precision and quality when creating any microporous SiC Chuck. Complete surface flatness, parallelism, and roughness are achievable with the Microporous SiC Chuck, and the grooves that typically exist on many other standard types of chucks are absent from the surface of the Microporous SiC Chuck, resulting in significantly less build-up of particles and much easier cleaning and maintenance than the majority of standard chucks. This enhances the reliability of Microporous SiC Chucks for all contamination-sensitive applications.

Wide Applications

Semicorex Microporous SiC Chucks are produced in many customizable configurations to accommodate the wide variety of process tools and applications utilized within semiconductor manufacturing. Several available configurations include various types of diameters, thicknesses, levels of porosity, vacuum interfaces, and mounting types. The Semicorex Microporous SiC Chuck is also designed to work with virtually all substrate materials, including silicon, silicon carbide, sapphire, gallium nitride (GaN), and glass. Thus, the Semicorex Microporous SiC Chuck can be readily integrated into various OEM equipment and process platforms already in use by customers.

Semicorex Microporous SiC Chucks offer significantly improved stability and predictability within your manufacturing process as well as increased equipment uptime. Consistent vacuum adsorption across the workpiece guarantees the proper alignment of the wafer throughout all critical operations including lithography, etching, deposition, polishing, and inspection. The superior durability and resistance to wear associated with microporous SiC lead to lower replacement rates and thus a reduction in preventative maintenance expenses and overall lifetime costs associated with these devices.

Semicorex Microporous SiC Chucks present a dependable, high-performance method for handling next-generation wafers. The combination of uniform vacuum distribution with superior thermal and chemical stability, excellent mechanical integrity, and superior cleanability results in Semicorex vacuum chucking solutions that form an integral part of the advanced semiconductor manufacturing process with consistency, confidence, and reliability.