- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

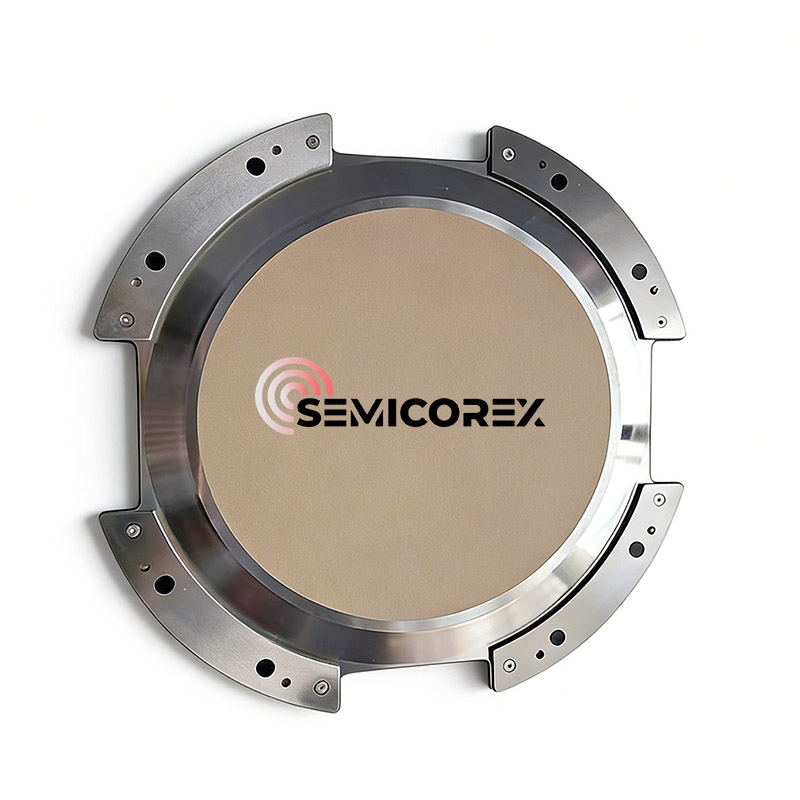

Microporous Ceramic Chuck

Semicorex microporous ceramic chuck is engineered to provide uniform, stable vacuum holding for precision manufacturing processes where flatness, cleanliness, and repeatability are critical. Designed for OEM integration, Semicorex leverages advanced ceramic materials and controlled microporous structures to deliver reliable chucking performance across demanding industrial applications.*

Send Inquiry

Semicorex microporous ceramic chuck as the key component in wafer handling in the semiconductor. As the core part of the microporous ceramic chuck, the holes of microporous ceramic usually are extremely small , the porosity is required to be about 30%~50%. The diameter of the hole is required to be micro-level, even nano-level. It can guarantee the workpiece to be firmly attached on the vacuum chuck, prevent the bad factors with the surface scratches, dent, and etc, due to the negative pressures. At the meantime, when use Alumina vacuum chuck during the photolithography process of electronic components, it usually requires the porous Alumina ceramic chuck to be black, to avoid interference caused by stray light reflected from the chuck.

Because the structure of alumina vacuum chucks is relatively simple, the manufacturing and maintenance costs are low, and the adsorption force is also relatively easy to adjust, the wafer can be absolutely stable and fixed during the processing by adjusting the working state of the vacuum pump or the spacing between the chucks. However, when the wafer is processed in the vacuum or low pressure environment like chemical vapor deposition, the vacuum chuck rely on the pressure difference cannot work, which limit its applications. Additional, when the wafer is absorbed on the surface of the microporous ceramic chuck, it will be deformed due to the air pressure, then the wafer may bounce back after processing, resulting in a wavy surface on the cut surface, reduced surface flatness, and impact on processing accuracy. So, the microporous ceramic chuck is typically employed in fix or carry some flat and well sealed components, such as metal plate. And in the semiconductor processing, it normally applied in the low-end process.

Semicorex microporous ceramic chucks are high-precision vacuum holding components designed for applications requiring uniform clamping force, excellent flatness, and contamination-free operation. Developed for OEM equipment manufacturers and advanced production environments, Semicorex ceramic chucks provide stable and repeatable workpiece fixation where mechanical clamping or conventional vacuum chuck designs are insufficient.

Key Performance Features

Uniform Vacuum Distribution Across the Entire Surface

Unlike conventional vacuum chucks that rely on discrete vacuum holes, Semicorex microporous ceramic chucks utilize a fully interconnected microporous structure to distribute vacuum evenly across the chuck surface.

This design provides:

Uniform holding force over the full contact area

Reduced localized stress and workpiece deformation

Improved stability for thin, brittle, or flexible substrates

As a result, these chucks are especially suitable for silicon wafers, glass panels, sapphire substrates, ceramics, and composite materials.

High Flatness and Dimensional Stability

Semicorex microporous ceramic chucks are manufactured using precision sintering and surface finishing processes to achieve high flatness and long-term dimensional stability.

Typical flatness can be controlled within micron-level tolerances, depending on size and application

Low thermal expansion minimizes deformation under temperature fluctuations

This ensures consistent positioning accuracy in grinding, polishing, inspection, and lithography-related processes.

Clean, Particle-Free Operation

Advanced ceramic materials are inherently non-metallic, non-magnetic, and corrosion-resistant, making Semicorex microporous ceramic chucks suitable for clean and sensitive manufacturing environments.

Key advantages include:

No metal contamination

Low particle generation

Compatibility with cleanroom applications

These properties make them ideal for semiconductor manufacturing, optical component production, and precision electronics processing.

Material & Structural Advantages

Controlled Microporous Ceramic Structure

The pore size and porosity of Semicorex microporous ceramic chucks are carefully engineered to balance vacuum flow rate, holding force, and mechanical strength.

Uniform pore distribution supports stable vacuum performance

Microporous structure reduces sudden pressure loss during operation

Improved holding reliability compared to drilled-hole vacuum chucks

This structure ensures consistent chucking performance during continuous operation.

Typical Applications

Semicorex microporous ceramic chucks are widely used in:

Semiconductor wafer grinding and polishing

Glass, sapphire, and ceramic substrate processing

Optical component manufacturing

Precision machining and metrology systems

Their stable and repeatable performance makes them well suited for automated, high-precision production lines.

FAQ – Semicorex Microporous Ceramic Chuck

What is the main advantage of a microporous ceramic chuck?

It provides uniform vacuum holding force across the entire surface, minimizing deformation and improving process stability.

Are Semicorex ceramic chucks suitable for thin wafers?

Yes. They are especially effective for thin, brittle, or flexible workpieces that require even pressure distribution.

Can Semicorex microporous ceramic chucks be customized for OEM equipment?

Yes. Dimensions, porosity, and surface specifications can be tailored for OEM-specific applications.

How are microporous ceramic chucks maintained?

Routine cleaning is typically sufficient. The ceramic structure resists wear, corrosion, and chemical degradation.