- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramic Manufacturers, Suppliers, Factory

- View as

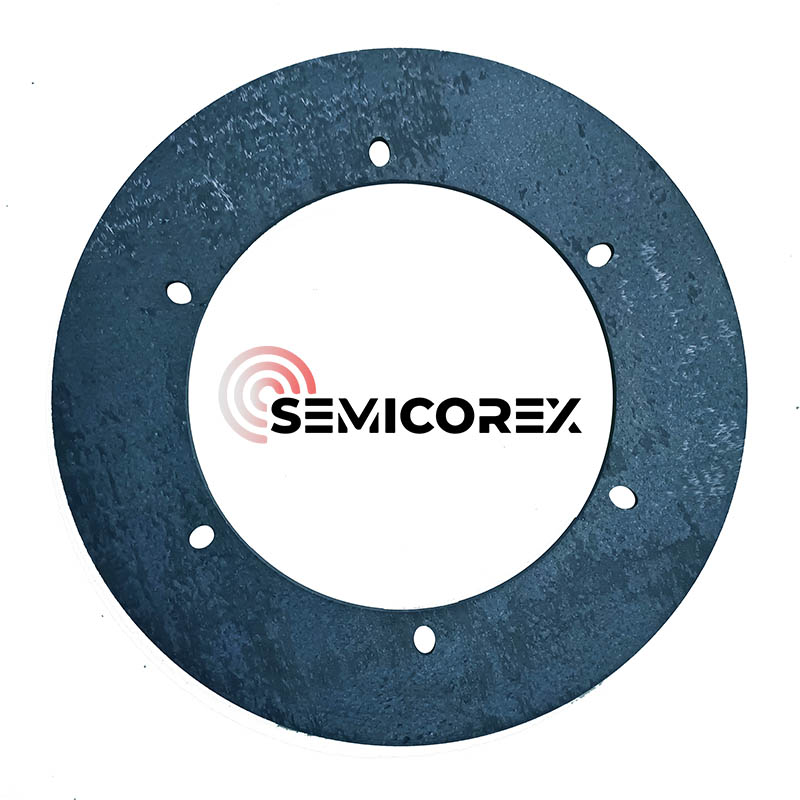

SSIC Sealing Rings

With superb hardness, excellent wear resistance, remarkable high-temperature resistance and strong chemical stability, SSIC sealing rings have become an irreplaceable sealing solution in modern machining processes. It can be fully compatible with challenging complex working conditions such as high temperature, high pressure and strong corrosion.

Read MoreSend InquiryCarbon Ceramic Discs

Semicorex Carbon Ceramic Discs are made of an advanced material, and are applied in braking systems in motorbikes, vehicles, and aircraft. Due to the material properties, carbon ceramic discs can significantly increase the lifespan and stability when rapidly running, and relatively strengthen the safety in driving. Semicorex delivers high-quality customized carbon ceramic discs based on customers’ needs.*

Read MoreSend InquiryPolycrystalline Alumina Fiberboard

Polycrystalline alumina fiberboard is a high-performance refractory plate material with excellent thermal shock resistance, strong corrosion resistance and superior oxidation resistance. This refractory performance makes it widely used in challenging high-temperature environments, including high-temperature furnaces, high-temperature kilns, high-temperature reactors, high-temperature pipelines, high-temperature furnace doors, high-temperature furnace walls. Choosing Semicorex, you will benefit from highly cost-effective prices, personalized one-on-one customization services, and exceptional product quality.

Read MoreSend InquiryZirconia Fiberboard

Semicorex zirconia fiberboard is an optimal lightweight refractory fiber material with capable of withstanding high-temperature oxidative environments above 1500℃ for extended periods. Relying on its exceptional high-temperature resistance, low thermal conductivity, and enhanced chemical stability, it serves as an impeccable thermal insulation solution to support manufacturing processes in high-temperature industrial sectors.

Read MoreSend InquiryCustomizable Ceramic Nozzles

Manufactured with punctilious attention to detail, customizable ceramic nozzles from Semicorex is the genius solution for controlling the flow rate of both gases and liquids with unparalleled uniformity and precision. Semicorex are looking forward to your further consultation.

Read MoreSend InquirySilicon Nitride Tube

Semicorex Silicon Nitride Tube is made by high performance Si3N4 material, the performance of strength, hardness, thermal conductivity is credible. Semicorex is committed to deliver qualified products worldwide.*

Read MoreSend Inquiry