- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

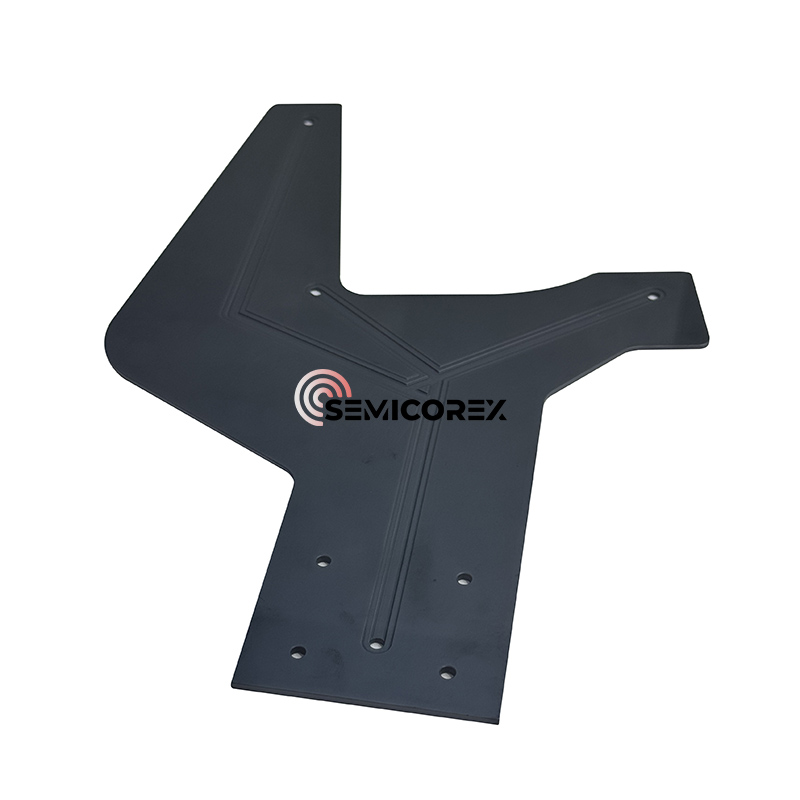

SiC Robot hands

Semicorex SiC Robot Hands are high-precision, ultra-clean end-effectors designed for safe and reliable wafer transfer in semiconductor manufacturing.Choose Semicorex for industry-leading expertise in advanced ceramics, delivering superior performance, purity, and customization trusted by top semiconductor fabs worldwide.*

Send Inquiry

Semicorex SiC Robot Hands are the latest in end-effectors designed for robotics wafer transfer applications in the field of semiconductor manufacturing. Made with high performance materials, we engineered these robotic hands with silicon carbide (SiC) ceramics to provide maximum thermal tabulation, chemical stability, and mechanical strength for an increasingly harsh environment of wafer fabrication or handling.

Central to our SiC Robot Hands is our proprietary advanced silicon carbide known for its high hardness (Mohs 9), high thermal conductivity, and corrosion resistance. Unlike traditional materials such as aluminum or stainless steel, SiC is compatible with the harsh processing environment of semiconductor cleanrooms including processed high temperatures and reactive gases. We offer long-term durability and minimize contamination, consistent with the strict purity required for wafer manufacturing.

![]()

Semiconductor equipment with SiC Robot Hands use negative pressure suction to obtain the wafer i.e., the semiconductor wafer is adsorbed on the quartz or ceramic finger using the suction cup principle followed by transportation using a mechanical action arm extending, rotating and lifting motions respectively.

"High speed" and "cleanliness" are the core characteristics of semiconductor wafer handling equipment. To meet these characteristics, the equipment has extremely stringent requirements on the performance of the components used. Since most processes are carried out in a vacuum, high temperature and corrosive gas environment, the handling arm used in the equipment must have excellent physical properties, such as: high mechanical strength, corrosion resistance, high temperature resistance, wear resistance, high hardness, insulation, etc., and advanced ceramic materials can just meet these conditions.

Silicon carbide ceramics have the physical properties of dense texture, high hardness, high wear resistance, as well as good heat resistance, excellent mechanical strength, good insulation in high temperature environment, good corrosion resistance and other physical properties. It is an excellent material for making semiconductor equipment handling arms.

Recognizing that robotic platforms vary across fabs and tool manufacturers, our SiC Robot Hands are available in a range of standardized sizes and can be customized for unique tool configurations. Mounting interfaces, finger geometries, and wafer support features can be tailored to meet specific equipment and process needs. Whether you are transferring wafers within cluster tools, vacuum chambers, or FOUP systems, our robot hands integrate seamlessly with leading robotics brands.

Every SiC Robot Hand undergoes rigorous cleaning, inspection, and packaging procedures to ensure compliance with Class 1 cleanroom standards. The non-porous, anti-static surface of SiC reduces particle adhesion, while the robust structure resists microfractures that could lead to particle generation over time. This makes them ideal for front-end wafer processes where even the slightest contamination can lead to device failure.

From epitaxy and ion implantation to PVD, CVD, and CMP, SiC Robot Hands are trusted in every step of semiconductor device fabrication. Their superior resistance to thermal shock and plasma environments makes them indispensable in advanced logic and power semiconductor lines, especially where SiC wafer substrates are used.