- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

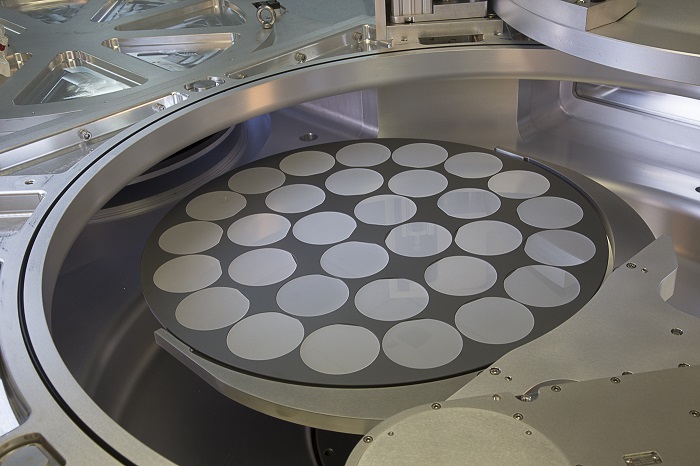

SiC Coated Wafer Carriers

Semicorex SiC Coated Wafer Carriers are high-purity graphite susceptors coated with CVD silicon carbide, designed for optimal wafer support during high-temperature semiconductor processes. Choose Semicorex for unmatched coating quality, precision manufacturing, and proven reliability trusted by leading semiconductor fabs worldwide.*

Send Inquiry

Semicorex SiC Coated Wafer Carriers are advanced components that support wafers for high-temperature processes in semiconductor applications such as epitaxial growth, diffusion, and CVD. The carriers provide structural benefits from high-purity graphite combined with maximum surface benefits by using a dense and uniform SiC coating for optimum thermal stability, chemical resistance, and mechanical strength under arduous processing conditions.

High-Purity Graphite Core for Optimum Thermal Conductivity

The SiC Coated Wafer Carriers are a substrate material of ultra-fine grain, high-purity graphite. It is an efficient thermal conductor, being both light and machinable, it can be fabricated into complex geometries which are required by the unique wafer size and process factors. Graphite offers uniform heating at the wafer surface limiting the occurrence of thermal gradients and thermal processing defects.

Dense SiC Coating for Surface Protection and Process Compatibility

The graphite carrier is coated with high purity, CVD silicon carbide. The SiC coating provides impermeable, pore free protection against corrosion, oxidation and process gas contamination from species such as hydrogen, chlorine and silane. The end result is a low-particulate, tough carrier that does not degrade or lose dimensional stability, choose to subject to numerous thermal cycles and represents a significantly decreased potential for wafer contamination.

Benefits and Key Features

Thermal Resistance: SiC coatings are stable to temperatures exceeding 1600°C, which is optimized for high temperature epitaxy and diffusion needs.

Excellent Chemical Resistant: It withstands all corrosive process gases and cleaning chemicals, and allows for longer life and less downtime.

Low Particle Generation: The SiC surface minimizes flaking and particle shedding, and keeps clean the process environment that is vital for device yield.

Dimension Control: Precisely engineered to close tolerances to ensure uniform wafer support so that it can be automatically handled with wafers.

Cost Reduction: Longer life cycles and lower maintenance needs provide lower total cost of ownership (TCO) than traditional graphite or bare carriers.

Applications:

SiC coated wafer carriers are widely used in the manufacturing of power semiconductors, compound semiconductors (such as GaN, SiC), MEMS, LEDs, and other devices requiring high-temperature processing in aggressive chemical environments. They are particularly essential in epitaxial reactors, where surface cleanliness, durability, and thermal uniformity directly influence wafer quality and production efficiency.

Customization and Quality Control

Semicorex SiC coated wafer carriers are produced under strict quality control protocols. We also have flexibility with standard sizes and configurations, and we can custom engineer solutions that meet customer requirements. Whether you have a 4-inch or 12-inch wafer format we can optimize wafer carriers for horizontal or vertical reactors, batch or single wafer processing, and specific epitaxy recipes.