- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

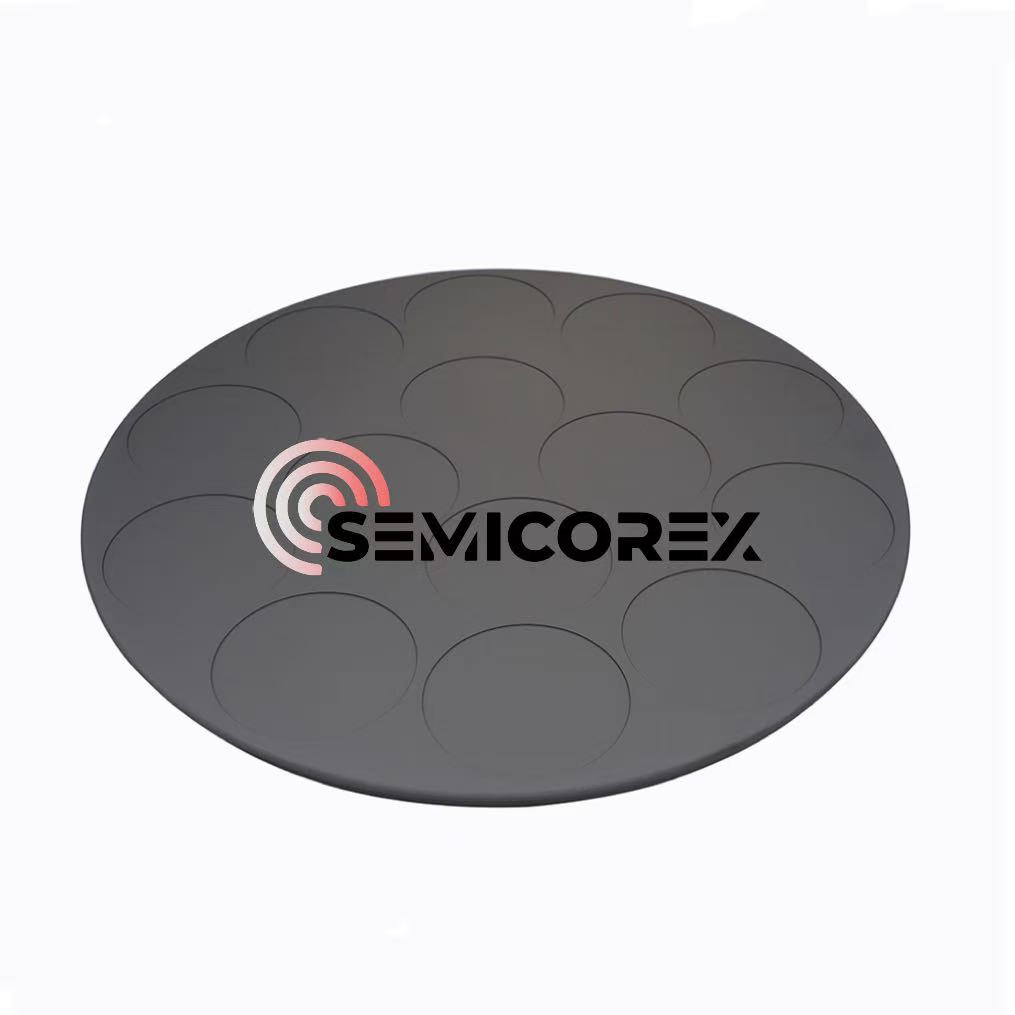

China Thin Film Deposition Edge Ring Manufacturers, Suppliers, Factory

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Thin Film Deposition Edge Ring,Etch Residue Ring,Semiconductor Focus Ring Coating,Custom Focus Ring Solutions,High-Temperature Focus Rings, If you are fascinated in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly, we will reply you within just 24 hours and also the best quotation might be provided.

Thin Film Deposition Edge Ring, Our company has already had a lot of top factories and expert technology teams in China, offering the best solutions, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

Hot Products

Barrel Susceptor with SiC Coating in Semiconductor

If you're looking for a high-quality graphite susceptor coated with high-purity SiC, the Semicorex Barrel Susceptor with SiC Coating in Semiconductor is the perfect choice. Its exceptional thermal conductivity and heat distribution properties make it ideal for use in semiconductor manufacturing applications.TaC Coated Rings

As the professional manufacture, we would like to provide you TaC Coated Rings. Introducing the CVD Tac Coated Ring, a state-of-the-art solution for semiconductor equipment. This cutting-edge product boasts an advanced chemical vapor deposition (CVD) coating that provides exceptional durability and resistance to wear and tear.Tantalum Carbide Coated Graphite Parts

Semicorex provide high-quality Tantalum Carbide Coated Graphite Parts with customized service. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Coating Heater

The CVD SiC coating of Semicorex SiC Coating Heater offers superior performance in protecting heating elements from the harsh, corrosive, and reactive environments often encountered in processes such as Metal-Organic Chemical Vapor Deposition (MOCVD) and Epitaxial Growth.**Satellite Plate

Semicorex Satellite Plate is a critical component used in semiconductor epitaxy reactors, specifically designed for Aixtron G5+ equipment. Semicorex combines advanced material expertise with cutting-edge coating technology to deliver reliable, high-performance solutions tailored for demanding industrial applications.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.