- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

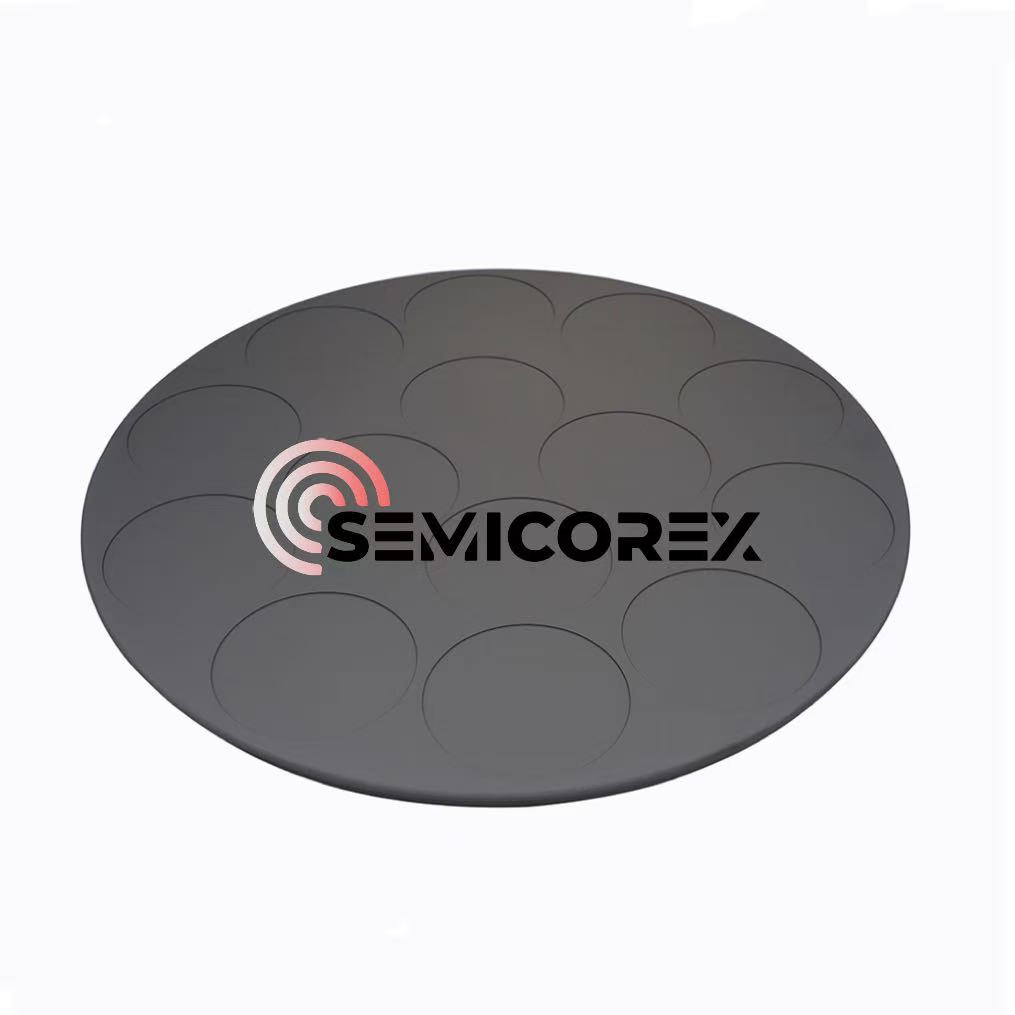

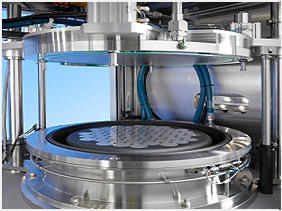

SiC-coated graphite MOCVD susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.

Send Inquiry

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy.

In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.

Semicorex chooses the high-purity graphite as the matrix material for its SiC-coated graphite MOCVD susceptors and then uniformly coats the graphite matrix with the silicon carbide coating via CVD technology. Compared to the conventional technology, the CVD technology significantly improves the bonding strength between the silicon carbide coating and the graphite matrix, resulting in a denser coating with stronger adhesion. Even under the demanding high-temperature corrosive atmosphere, the silicon carbide coating maintains its structural integrity and chemical stability over a long period, effectively preventing direct contact between corrosive gases and the graphite matrix. This effectively avoids corrosion of the graphite matrix and prevents graphite particles from detaching and contaminating wafer substrates and epitaxial layers, ensuring the cleanliness and yield of semiconductor device fabrication.

The Advantages of Semicorex’s SiC-coated graphite MOCVD susceptors

1. Excellent corrosion resistance

2. High thermal conductivity

3. Superior thermal stability

4. Low coefficient of thermal expansion

5. Exceptional thermal shock resistance

6. High surface smoothness

7. Enduring service life