- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China GaN Wet Etching Manufacturers, Suppliers, Factory

To frequently enhance the administration program by virtue on the rule of "sincerely, very good faith and high-quality are the base of enterprise development", we widely absorb the essence of related products internationally, and consistently develop new products to fulfill the calls for of customers for GaN Wet Etching,icp etching,GaN Plasma Etching,GaN Etch for LEDs,Silicon Carbide Etching, With our rules of " organization track record, partner trust and mutual benefit", welcome all of you to function together , improve jointly.

GaN Wet Etching, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent for you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Hot Products

8 Inch N-type SiC Wafer

Semicorex provides various types of 4H and 6H SiC wafers. We have been manufacturer and supplier of wafers for many years. Our 8 Inch N-type SiC Wafer has a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.SiC Cantilever Paddle

Semicorex SiC (Silicon Carbide) Cantilever Paddle is a crucial component used in semiconductor manufacturing processes, particularly in diffusion or LPCVD (Low-Pressure Chemical Vapor Deposition) furnaces during processes like diffusion and RTP (Rapid Thermal Processing). The SiC Cantilever Paddle is to carry semiconductor wafers securely within the process tube during various high-temperature processes such as diffusion and RTP. It serves the purpose of supporting and transporting wafers within the process tube of these furnaces. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Silicon Substrate

Semicorex Silicon substrate, serves as the canvas upon which intricate electronic circuits are crafted. Derived from silicon, one of the most abundant elements in the Earth's crust, this crystalline substrate forms the fundamental material for manufacturing semiconductor devices. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Susceptor for ICP Etch

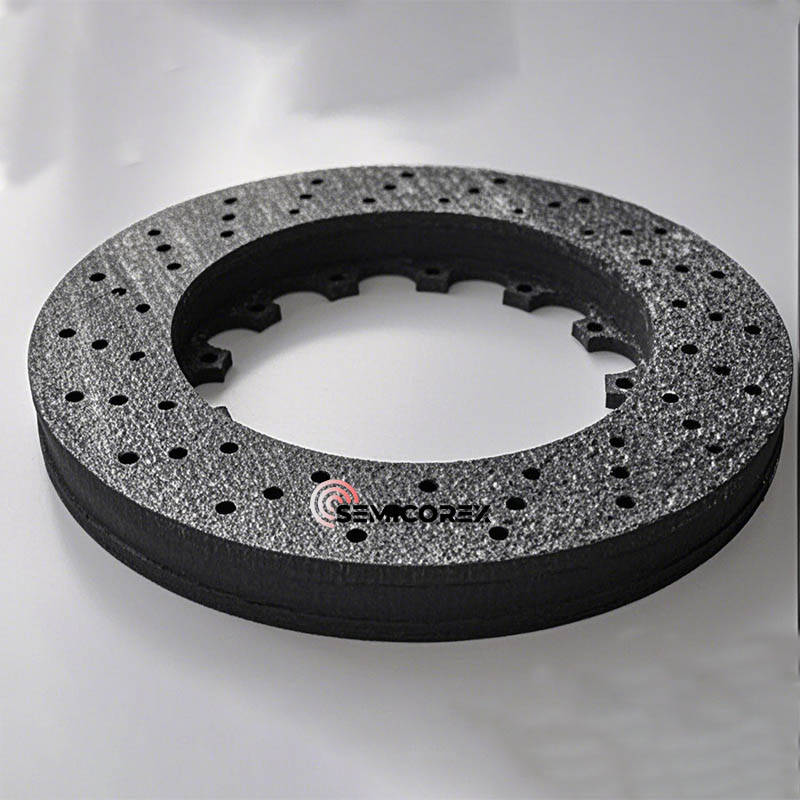

Semicorex SiC Susceptor for ICP Etch is manufactured with a focus on maintaining high standards of quality and consistency. The robust manufacturing processes used to create these susceptors ensure that each batch meets stringent performance criteria, delivering reliable and consistent results in semiconductor etching. Additionally, Semicorex is equipped to offer fast delivery schedules, which is crucial for keeping pace with the rapid turnaround demands of the semiconductor industry, ensuring that production timelines are met without compromising on quality.We at Semicorex are dedicated to manufacturing and supplying high-performance SiC Susceptor for ICP Etch that fuse quality with cost-efficiency.**Wafer Cassette Box

Semicorex Wafer Cassette Box is a PFA fluoroplastic cassette with a large opening area, designed to improve wafer washing and drying performance in semiconductor manufacturing. Choose Semicorex for its proven track record of delivering high-quality, durable, and chemically resistant wafer handling solutions.*Gas Distribution Plates

Semicorex Gas Distribution Plates, made of CVD SiC is a critical component in plasma etching systems, designed to ensure uniform gas dispersion and consistent plasma performance across the wafer. Semicorex is the trusted choice for high-performance ceramic solutions, offering unmatched material purity, engineering precision, and dependable support tailored to the demands of advanced semiconductor manufacturing.*