- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

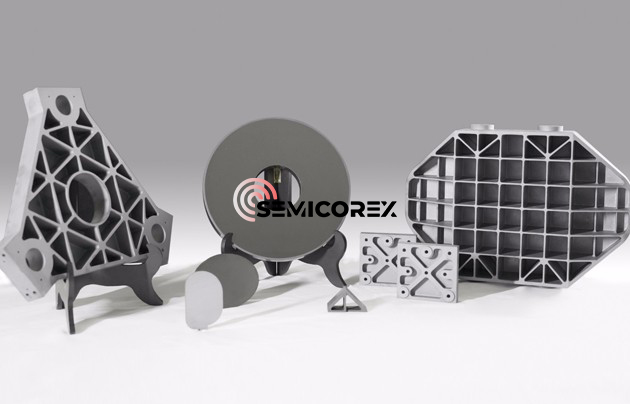

SiC Fin

Semicorex SiC Fin is a high-purity silicon carbide ceramic component precisely engineered with a perforated disk structure for efficient gas and liquid flow management in epitaxy and etching equipment. Semicorex delivers customized, high-precision components that ensure superior durability, chemical resistance, and performance stability in semiconductor process environments.*

Send Inquiry

Semicorex SiC Fin is a high-performance component made of silicon carbide ceramic, it is designed for use in semiconductor epitaxy and etching systems. Designed as a circular, disk-shaped piece with various drilled holes of differing diameters, the SiC Fin is a critical component for flow-patterning materials and exhaust management of gases or liquid effluents during high-temperature or plasma processing. Due to its structural performance, excellent corrosion-resistance, and high thermal stability, the SiC Fin is critical for advanced manufacturing for semiconductors.

SiC Fin is manufactured from high-purity silicon carbide powder using advanced forming and sintering processes. Thus, it has excellent mechanical strength and stability at high thermal and chemical conditions. The unique physical properties of silicon carbide such as high hardness, low thermal expansion, and excellent chemical inertness allow the Fin to be a structural component in high-temperature plasma or reactive gas environments, which are characteristic of EPI and etching processes.

The component's disk structure, complete with precisely drilled holes, allows for controlled flows of gases and liquids throughout process chambers. Depending on the application, the holes can be configured to manage the flow of by-products or drainage for a clean and stable environment during wafer process. In an epitaxy application, for example, the SiC Fin can assist in directing process gases or condensate flows, thereby enhancing film uniformity and minimizing particle contamination. In etch tools, it is effective for the safe and efficient removal of reactive species and liquid by-products protecting vulnerable chamber components from chemical degradation.

Each Semicorex SiC Fin is manufactured with very tight tolerances and polished to deliver excellent surface flatness and dimensional accuracy. This manufacturing precision ensures reliable performance when integrated into complicated systems and retaining consistent functionality for long periods of operation. The SiC Fin is compatible with all reactor designs and can be custom manufactured in diameter, thickness and hole pattern to meet customer needs. Semicorex can offer custom designs to performance optimize for process variables such as flow rate, chamber geometry and temperature.

In addition to its versatile functionality, the SiC Fin has exceptional durability and longevity as compared to other materials. It is highly resistant to oxidation, plasma erosion, and chemical corrosion, which reduces the frequency of replacement of your parts and decreases system down time. Moreover, the thermal conductivity of silicon carbide allows heat dissipating capacity to manage thermal gradients in the device, avoiding unwanted warping or cracking during quick temperature cycling.

Semicorex uses advanced ceramic processing and CVD coating capabilities to provide the highest purity and consistency of the SiC Fin produced. Each SiC Fin is also inspected for density, microstructure uniformity, and surface perfection to ensure it meets the demanding requirements of the semiconductor industry. This results in a component that has mechanical integrity and robustness for stable, long term operation in extreme environments.

The Semicorex SiC Fin is the result of state-of-the-art materials science and engineering technology. Not only does it manufacturers effective exhaust and liquid flows, but contributes to the cleanliness and reliability of the entire epitaxy and etching systems. It combines mechanical strength, thermal stability, and corrosion longevity to provide a more consistent experience for semiconductor processing applications.