- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

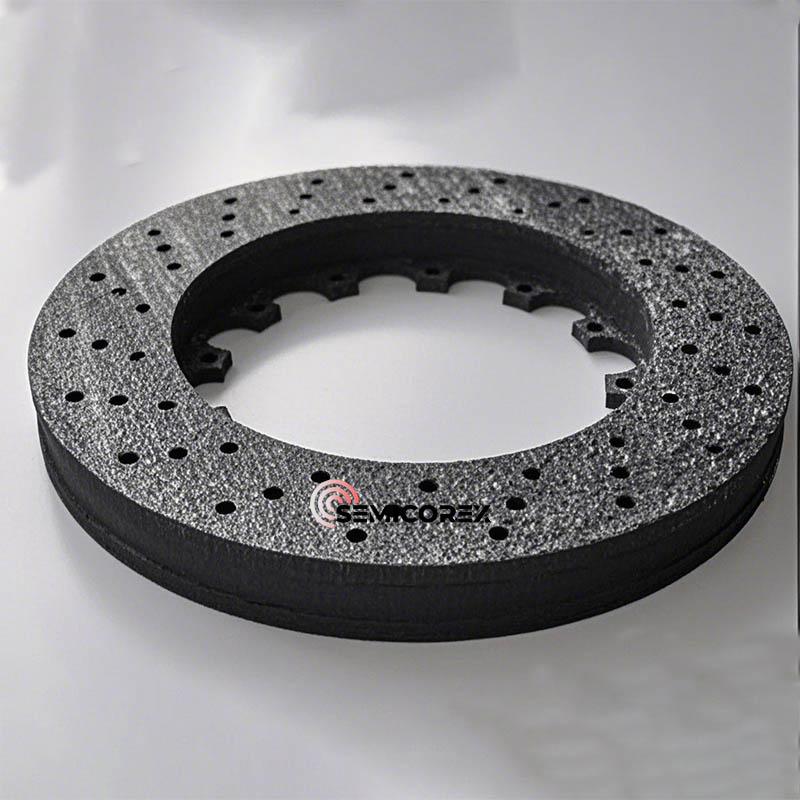

Carbon Ceramic Brake Disc

Semicorex Carbon ceramic brake disc is a brake disc made of a new type of carbon silicon ceramic composite material. Choosing Semicorex ensures access to internationally recognized quality, cutting-edge technology, and scalable manufacturing capabilities.*

Send Inquiry

Semicorex Carbon ceramic brake disc is made by C/C-SiC matrix composite. With a three-dimensional felt or woven body of carbon fiber as a reinforcing skeleton, the matrix is composed of carbon (C) and silicon carbide (SiC), which is a dual-matrix composite material. It combines the advantages of carbon materials and silicon carbide, with high toughness, low density, good thermal stability, thermal shock resistance, high hardness, high wear resistance and good oxidation resistance. In high temperature environments, the carbon matrix can provide a certain buffer and toughness to prevent the material from brittle cracking, and can withstand a high temperature of at least 1650°C. First prepare a C/C composite material, and then introduce the SiC phase by methods such as liquid silicon impregnation. For example, a C/C blank is first prepared by chemical vapor deposition or resin impregnation carbonization, and then the blank is contacted with liquid silicon. Silicon reacts with carbon at high temperature to form SiC, while filling the pores in the blank. Due to its excellent comprehensive performance, it is widely used in advanced fighter jets, high-speed trains, racing cars and sports cars, and can meet the strict requirements of these high-end equipment for the brake system under complex working conditions such as high speed, high load and high temperature.

The carbon ceramic brake disc is part of the automobile braking system. In addition to the brake disc, the disc brake also has calipers, brake pads, brake pipes and other parts. The brake disc rotates with the wheel. The brake pad is installed inside the caliper and is stationary relative to the brake disc.

The principle of automobile braking is relatively simple. When the driver steps on the brake, the brake oil in the brake pipe acts as a hydraulic medium to apply pressure to the piston in the caliper, so that the brake pad holds the brake disc tightly, and the friction force stops the brake disc from rotating, thereby playing a role in deceleration or parking. The number of pistons in the caliper determines the pressure applied to the brake pad. The material of the brake disc and brake pad affects the strength of the friction coefficient.

There are three main materials for brake discs: gray cast iron, carbon-carbon and carbon ceramic. The latter two are carbon-based composite materials, but they have different characteristics.

1. Gray cast iron brake discs are characterized by mature technology and low price, but lack of performance. The biggest defect of cast iron discs is high temperature thermal decay. From the perspective of energy conversion, automobile braking is actually a process of converting kinetic energy into thermal energy. Therefore, the temperature will be very high during the braking process. In the case of continuous braking, the traditional cast iron disc will cause obvious thermal decay due to high temperature. As the temperature rises, the friction will decrease. This will cause the brakes to become softer and softer.

2. The emergence of carbon/carbon and carbon ceramic brake disc is to solve the performance shortcomings of cast iron discs.

Whether it is carbon/carbon or carbon/ceramic, carbon-based composite brake discs have high friction coefficients, light weight, and good resistance to thermal decay and corrosion.

- Carbon/carbon brake discs have two obvious shortcomings. One is that the friction coefficient decays more severely in wet conditions, and the other is that the friction coefficient is also discounted in low temperature environments. Such product characteristics restrict the development of carbon/carbon brake discs in the civilian market. Therefore, carbon/carbon material brake discs are mainly used in military aircraft and F1 racing cars.

- carbon ceramic brake disc is an improved version of carbon/carbon materials. The manufacturing process is based on carbon-carbon materials and silicon carbide is added. The high mechanical strength of carbon fiber is combined with the wear resistance and oxidation resistance of ceramic materials. Carbon ceramic brake disc not only inherit the advantages of high temperature resistance and low density of carbon-carbon materials, but also overcome the problem of low friction coefficient in wet and low temperature environments. Therefore, carbon ceramic brake disc can be used in both the civilian market and the racing and military aircraft markets. Carbon-ceramic discs can withstand high temperatures of up to 1750°C, have a short braking distance, are light in weight, and are rust-free.