- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

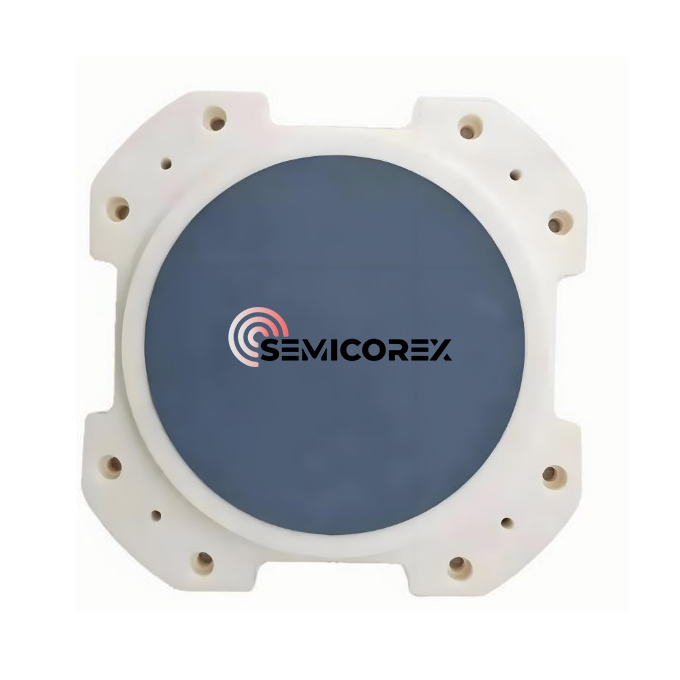

Silicon Carbide Chucks

Semicorex silicon carbide chucks are specially designed for photolithography equipment and have multiple advantages such as high precision, ultra-light weight, high stiffness, low coefficient of thermal expansion, and excellent wear resistance.

Send Inquiry

Semicorex silicon carbide chucks are functional adsorption devices made of silicon carbide (SiC) ceramic material. They are mainly used in semiconductors, photovoltaics, precision manufacturing and other scenarios that have extremely high requirements for high temperature resistance, wear resistance, chemical corrosion resistance and cleanliness of materials.

SiC ceramic material has high temperature resistance and maintains its structural stability in high temperature environments. Its excellent thermal conductivity allows it to quickly dissipate heat generated during adsorption, preventing overheating of the workpiece. The material's exceptional hardness makes it suitable for gripping rough or hard workpieces. In addition, the chemical inertness of SiC ceramic material makes it resistant to corrosion by strong acids, strong alkalis and organic solvents. The low impurity precipitation performance of this material avoids impurity contamination and prolongs the normal operation time of the equipment, meeting the ultra-clean requirements of the semiconductor industry.

Typical characteristics of Semicorex silicon carbide chucks

1.High precision: flatness is 0.3-0.5μm.

2.Mirror polishing

3.Ultra-light weight

4.High stiffness

5.Low coefficient of thermal expansion

6.Excellent wear resistance

The application Scenarios of silicon carbide chucks

Semiconductor manufacturing

Wafer transfer and processing: In processes such as photolithography and etching, the wafer needs to be stably adsorbed in a vacuum environment to avoid displacement errors.

Plasma corrosion resistance: In the semiconductor etching process, excellent corrosion resistance can extend the service life of the product.

Photovoltaic cell production

Silicon wafer cutting: Adsorbs silicon wafers to resist cutting vibration and reduce the fragmentation rate of silicon wafers.

Precision optics and electronics manufacturing

Sapphire substrate processing: Sapphire substrates used in LED chip manufacturing require vacuum adsorption. The adsorption force must overcome the weight of the substrate and avoid scratching the product surface.

Silicon carbide chucks have become key consumables in the high-end manufacturing field due to their excellent performance, promoting technological progress in industries such as semiconductors, photovoltaics and recision manufacturing.