- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

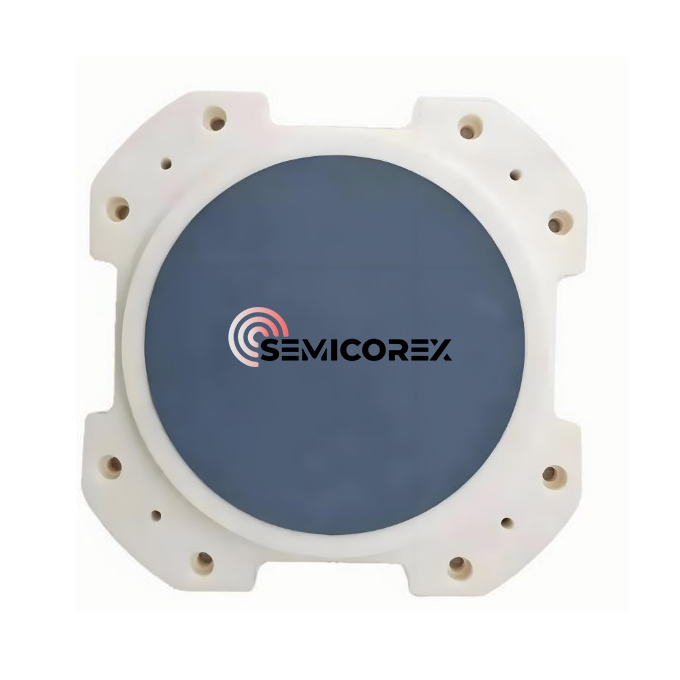

Porous Alumina Chucks

Semicorex Porous Alumina Chucks are microporous black alumina vacuum fixture with 35–40% porosity, designed to provide uniform suction and safe wafer handling in semiconductor manufacturing. Choosing Semicorex means reliable ceramic engineering, superior material quality, and consistent performance that safeguard yield and process stability.*

Send Inquiry

Semicorex Porous Alumina Chucks are purpose-built for the most delicate wafers. Their porous design provides the assurance of consistent vacuum distribution across the chuck surface, which ensures reduced localized stress, and aids in preventing edge chipping and breakage. Mechanical clamping (solid or otherwise) is not as effectual as the microporous network which holds even delicate wafers without the over constraining mechanical stress while also fixing the wafer safely, as the microporous structure prevents wear and provides a gentle hold. The need for uniform adsorption across the entire chuck surface is especially critical for wafers that are larger and thinner that can tolerate much less stress during automated handling and while executing high precision processing steps.

Optimized for 35-40% porosity, the chuck develops a network of inter-connecting pores that serve to evacuate the air while providing enough mechanical strength to hold the wafer in place against process forces. This means the vacuum holding force remains stable while moving the wafers, even in rapid succession, while performing a complex process sequence. Adsorption within a microporous network provides more stability than through simply creating differences in pressure within the vacuum system.

The black alumina (Al₂O₃), itself is the ultimate material because it is hard, wear-resistant, and chemically inert. It will not degrade any appreciable surface and is unaffected through repeated cycles of the wafer (placement/ vacuum adsorption/cooling). The black alumina is dimensionally stable, therefore will not change despite temperature changes that occur naturally during the process (heating and cooling) or in the environment.

Chemical resistance is another key advantage of black alumina. The chuck can operate in aggressive cleaning, plasma, and etching environments without compromising its structural integrity. Its inertness prevents contamination of the wafer surface, ensuring high process purity and adherence to cleanroom standards.

The microporous structure also offers a supportive surface that relieves stress concentration on thin and brittle wafers. In tandem with precise surface flatness and smooth surface finish, the Porous Alumina Chucks will minimize the occurrence of micro-cracks and scratches that could compromise the integrity of the wafer at-hand.

Alumina ceramic has superb hardness, high mechanical strength, low thermal coefficient of expansion, and excellent thermal stability making it a practical material for a precision semiconductor application. Also, its chemical inertness means it can withstand acids, alkalis, and plasma, while wear-resistance properties ensure durability, these advantages make alumina the material of choice for microporous vacuum chucks and provide both reliability and predictability of performance.

In conclusion, the Porous Alumina Chucks are designed to supply uniform and survivable wafer handling. its microporous black alumina structure offers even vacuum adsorption (uniformity) while minimizing mechanical stress and reduction of wafer damage. As a chuck, the substantial and optimal porosity together with outstanding thermal, mechanical, and chemical properties, helps optimize wafer safety, value, and reliability of operation in harsh fabrication conditions. The excellent combination of robust, uniform, and safe handling that the Porous Alumina Chucks can offer manufacturers are simply rare and unique.