- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

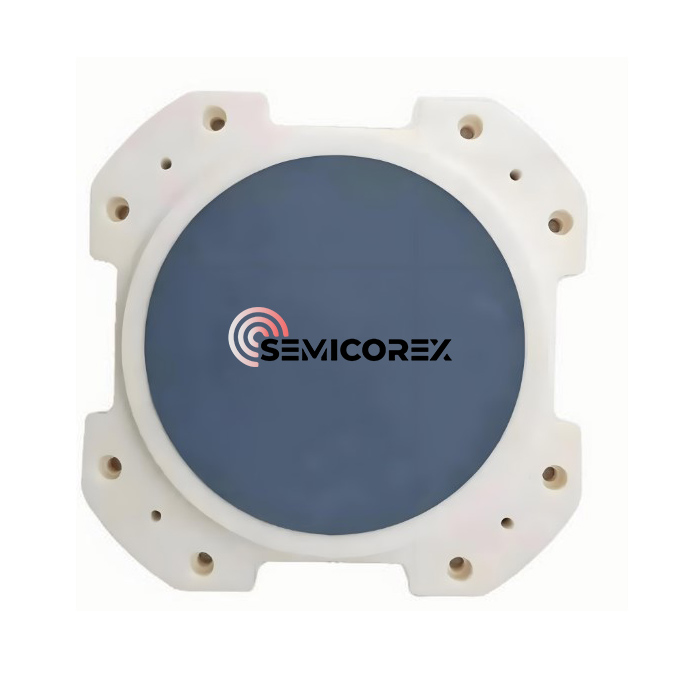

Al2O3 Vacuum Chucks

Semicorex Al2O3 Vacuum Chucks are microporous ceramic adsorption fixture made from black alumina with a porosity of 35–40%, specifically designed for wafer handling in semiconductor applications. Choosing Semicorex means benefiting from advanced ceramic technology, precision engineering, and reliable product quality that ensure stable performance in demanding cleanroom environments.*

Send Inquiry

Semicorex Al₂O₃ Vacuum Chucks are precision microporous ceramic component developed for wafer handling, fixation, and processing applications in the semiconductor industry. Made from black alumina with a controlled porosity of 35%-40%, it is an extremely stable, clean, and reliable medium for vacuum adsorption processes. The chuck combines the ceramic processing of the substrate onto a functional surface using advanced manufacturing techniques to provide consistent suction performance for the user's fragile wafer during critical process steps.

Black alumina (Al₂O₃); has a unique balance of mechanical strength, hardness, and chemical resistance when compared to metals and polymers. The microporous structure is optimized for controlled porosity to provide consistent vacuum distribution across the surface of the vacuum chuck. Consistent vacuum distribution throughout the full surface area of a wafer chuck minimizes localized stress concentrations, limiting the risk of wafer distortion, edge chipping, and breakage. As wafer fabrication continues to scale up in diameter, and the geometries and devices become more fragile, process yield and improved wafer handling reliability become critical requirements.

The controlled porosity of 35–40% represents a key characteristic of this vacuum chuck. An optimized pore network can minimize turbulence during air evacuation from the pore area, and maintain the holding force while preserving mechanical strength and durability. By contrast, mechanical clamps use plates that cause localized stress points and work against the mechanical properties of the individual wafer. The microporous alumina surface is, therefore, superior in holding wafers flat and incongruously during mechanical approaches. This makes for a perfect candidate for high-tech semiconductor processes that benefit from wafer flatness and smooth hold, including lithography, etching, deposition, and metrology.

From a thermal perspective, the black alumina material has excellent this ability to maintain dimensional stability during elevated temperature. With a low coefficient of thermal expansion, a vacuum chuck is able to stay accurate even during heating and cooling cycles, which is a critical aspect due to the rapid temperature fluctuation often occurring in wafer processing environments. Hardness and wear resistance of this ceramic also increase the longevity of the chuck, reducing the frequency of maintenance for equipment operators, and lowering the total cost of ownership.

The chemical inertness of alumina ceramics is yet another substantial property. In semiconductor fabs, the components of the equipment needs to tolerate aggressive chemicals, cleaning agents, or plasma environments without deterioration. Black alumina has excellent properties for resisting corrosion, oxidation, and/or surface contamination, and thereby retains structure and structural/phasic stability during excited operating cycle periods. This property in place also means that wafers are not subjected to contamination which protects circuit from how those devices perform, and also trusts the cleanroom protocols.

Not only does the Al₂O₃ Vacuum Chucks exhibit excellent functional performance, the surface finish is also tightly controlled. The finish is created using high-precision machining and polishing processes that yield uniform flatness and smoothness so that delicate wafers can be held with no scratches or surface damage. The highly engineered porosity of the material yields a suitable balance between suction and surface protection, allowing for adequate holding force on the wafer, while avoiding any damage to the thin, brittle substrates.

From an operational standpoint, the Al₂O₃ Vacuum Chucks are critical component in contemporary semiconductor manufacturing. It facilitates automation, allowing the wafers to be picked-up, placed, aligned, and processed, reliably satisfying the process requirements. The alumina's black color also aids and provides pragmatic advantages by reducing light reflection during optical inspections and measurement processes, especially where high-precision optical equipment is used.

Combining advanced ceramic technology with a well-considered design have yielded, in the Al₂O₃ Vacuum Chucks, a long-lasting, high-performance solution for semiconductor manufacturers' wafer handling challenges. The Al₂O₃ Vacuum Chucks improves productivity through reduced wafer loss, reduces downtime due to durability, and enhances process stability by providing consistent vacuum holding force.

Semicorex Al₂O₃ Vacuum Chucks made from microporous black alumina is more than just a fixture; it is a critical enabler of precision semiconductor manufacturing. With its optimized porosity, exceptional material properties, and robust performance, it ensures reliable wafer handling across the most demanding fabrication processes. For manufacturers seeking to achieve higher yield, improved process efficiency, and superior equipment performance, the black alumina vacuum chuck is an indispensable choice.