- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Icp etching equipment Manufacturers, Suppliers, Factory

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for Icp etching equipment,Silicon Carbide Plate,Silicon Carbide Ceramic,SiSiC,SIC, We sincerely be expecting exchange and cooperation with you. Allow us to move forward hand in hand and accomplish win-win circumstance.

Icp etching equipment, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to supply the high-quality merchandise and services, and promote lasting cooperation with our customers, common development and create a better future.

Hot Products

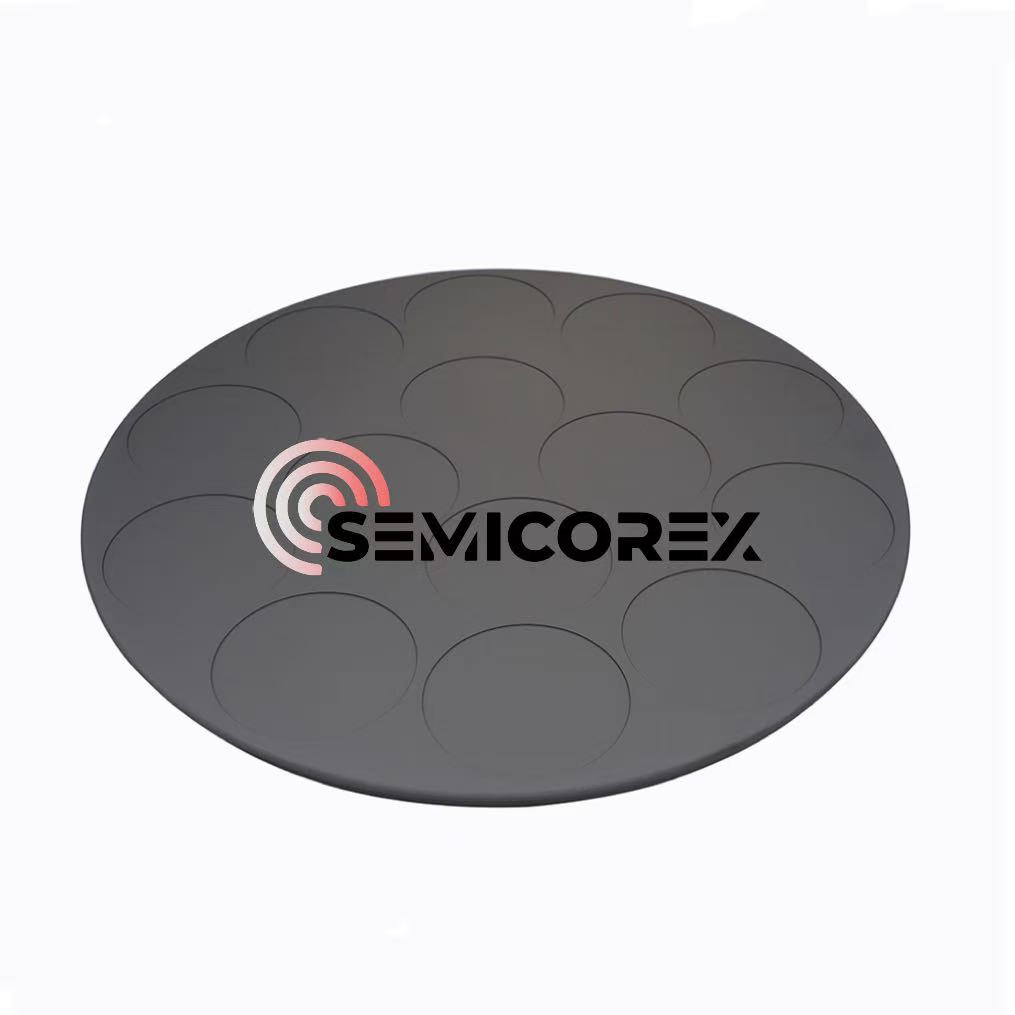

SiC Coated ICP Etching Carrier

Semicorex SiC Coated ICP Etching Carrier engineered specifically for epitaxy equipment with high heat and corrosion resistance in China. Our products have a good price advantage and cover many of the European and American markets. We look forward to becoming your long-term partner in China.Silicon Carbide Coating Graphite Susceptor for MOCVD

Semicorex is a trusted supplier and manufacturer of silicon carbide coating graphite susceptor for MOCVD. Our product is specially designed to cater to the needs of the semiconductor industry in growing the epitaxial layer on the wafer chip. The product is used as the center plate in MOCVD, with a gear or ring-shaped design. It has high heat and corrosion resistance, making it ideal for use in extreme environments.Spare Parts in Epitaxial Growth

Semicorex Spare Parts in Epitaxial Growth are crucial components utilized within epitaxial growth systems, particularly in processes involving quartz tube setups. These parts play a vital role in facilitating gas flow to drive tray base rotation and ensure precise temperature control throughout the epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC ICP Etching Disk

Semicorex SiC ICP Etching Disk is not merely components; it's essential enabler of cutting-edge semiconductor manufacturing as the semiconductor industry continues its relentless pursuit of miniaturization and performance, the demand for advanced materials like SiC will only intensify. It ensures the precision, reliability, and performance required to power our technology-driven world.We at Semicorex are dedicated to manufacturing and supplying high-performance SiC ICP Etching Disk that fuses quality with cost-efficiency.**SiC Focus Ring

Semicorex SiC Focus Ring is a high-purity silicon carbide ring component designed to optimize plasma distribution and wafer process uniformity in semiconductor manufacturing. Choosing Semicorex means ensuring consistent quality, advanced material engineering, and reliable performance trusted by leading semiconductor fabs worldwide.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.