- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramic Materials Manufacturers, Suppliers, Factory

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Ceramic Materials,Ceramic Seal,Industrial Seal,Graphite Seal,Sic Mechanical Seal, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services.

Ceramic Materials, What You Need Is What We Pursue.We are sure our products will bring you first class quality.And now sincerely hope to promote partner friendship with you from all over the world. Let's joint hands to cooperate with mutual benefits!

Hot Products

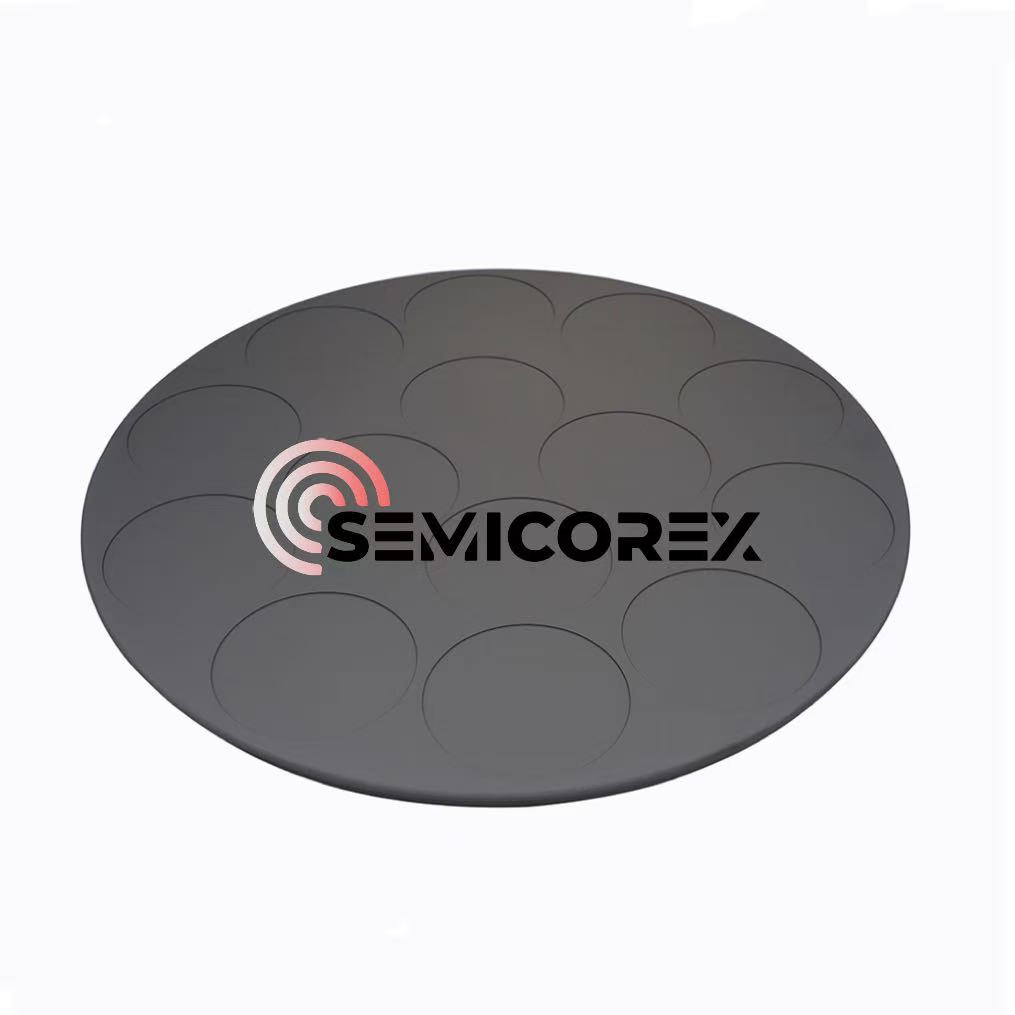

EPI 3 1/4" Barrel Susceptor

Semicorex SiC coating EPI 3 1/4" Barrel Susceptor provides excellent thermal stability and resistance to chemical attack, while the graphite substrate offers superior heat transfer properties.MOCVD Wafer Carriers for Semiconductor Industry

Semicorex MOCVD Wafer Carriers for Semiconductor Industry is a top-of-the-line carrier designed for use in the semiconductor industry. Its high-purity material ensures even thermal profile and laminar gas flow pattern, delivering high-quality wafers.Susceptor Semiconductor

Semicorex Susceptor Semiconductor, a revolutionary graphite susceptor meticulously crafted to elevate your semiconductor manufacturing to new heights. Engineered with precision and innovation, this susceptor boasts a CVD SiC coating that sets it apart in the industry. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Wafer Carriers with SiC Coating

The Semicorex Wafer Carriers with SiC Coating, an integral part of the epitaxial growth system, is distinguished by its exceptional purity, resistance to extreme temperatures, and robust sealing properties, serving as tray that is essential for the support and heating of semiconductor wafers during the critical phase of epitaxial layer deposition, thereby optimizing the overall performance of the MOCVD process. We at Semicorex are dedicated to manufacturing and supplying high-performance Wafer Carriers with SiC Coating that fuse quality with cost-efficiency.RTP SiC Coating Plates

Semicorex RTP SiC Coating Plates are high-performance wafer carriers engineered for use in demanding Rapid Thermal Processing environments. Trusted by leading semiconductor manufacturers, Semicorex delivers superior thermal stability, durability, and contamination control backed by rigorous quality standards and precision manufacturing.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.