- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

SiC Coated Graphite Trays

Semicorex SiC Coated Graphite Trays are high-performance carrier solutions specifically designed for AlGaN epitaxial growth in the UV LED industry. Choose Semicorex for industry-leading material purity, precision engineering, and unmatched reliability in demanding MOCVD environments.*

Send Inquiry

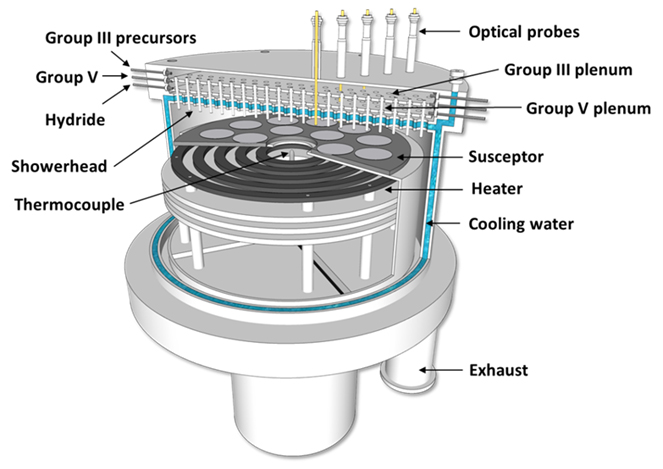

Semicorex SiC coated graphite trays are advanced materials engineered specifically for demanding epitaxial growth environments. In the UV LED industry, especially in the fabrication of AlGaN-based devices, these trays play a crucial role in ensuring uniform thermal distribution, chemical stability, and long service life during metal-organic chemical vapor deposition (MOCVD) processes.

The epitaxial growth of AlGaN materials presents unique challenges due to high process temperatures, aggressive precursors, and the need for highly uniform film deposition. Our SiC coated graphite trays are designed to meet these challenges by offering excellent thermal conductivity, high purity, and exceptional resistance to chemical attack. The graphite core provides structural integrity and thermal shock resistance, while the dense SiC coating offers a protective barrier against reactive species such as ammonia and metal-organic precursors.

SiC coated graphite trays is often used as a component to support and heat single crystal substrates in metal organic chemical vapor deposition (MOCVD) equipment. The thermal stability, thermal uniformity and other performance parameters of SiC coated graphite trays play a decisive role in the quality of epitaxial material growth, so it is the core key component of MOCVD equipment.

Metal organic chemical vapor deposition (MOCVD) technology is currently the mainstream technology for epitaxial growth of GaN thin films in blue light LEDs. It has the advantages of simple operation, controllable growth rate, and high purity of grown GaN thin films. The SiC coated graphite trays used for epitaxial growth of GaN thin films, as an important component in the reaction chamber of MOCVD equipment, needs to have the advantages of high temperature resistance, uniform thermal conductivity, good chemical stability, and strong thermal shock resistance. Graphite materials can meet the above conditions.

As one of the core components in MOCVD equipment, the SiC coated graphite trays is the carrier and heating element of the substrate substrate, which directly determines the uniformity and purity of the thin film material. Therefore, its quality directly affects the preparation of epitaxial wafers. At the same time, with the increase in the number of uses and changes in the working conditions, it is very easy to wear and tear, and it is a consumable.

Although graphite has excellent thermal conductivity and stability, which makes it a good advantage as a base component of MOCVD equipment, during the production process, graphite will be corroded and powdered due to the residual corrosive gas and metal organic matter, which will greatly reduce the service life of the graphite base. At the same time, the fallen graphite powder will cause pollution to the chip.

The emergence of coating technology can provide surface powder fixation, enhance thermal conductivity, and balance heat distribution, and has become the main technology to solve this problem. The graphite base is used in the MOCVD equipment environment, and the surface coating of the graphite base should meet the following characteristics:

(1)It can fully wrap the graphite base and have good density, otherwise the graphite base is easily corroded in corrosive gas.

(2)It has a high bonding strength with the graphite base to ensure that the coating is not easy to fall off after experiencing multiple high-temperature and low-temperature cycles.

(3) It has good chemical stability to avoid the coating from failing in a high-temperature and corrosive atmosphere.

SiC has the advantages of corrosion resistance, high thermal conductivity, thermal shock resistance, and high chemical stability, and can work well in the GaN epitaxial atmosphere. In addition, the thermal expansion coefficient of SiC is very close to that of graphite, so SiC is the preferred material for the surface coating of the graphite base.

Currently, the common SiC is mainly 3C, 4H and 6H types, and SiC of different crystal forms has different uses. For example, 4H-SiC can be used to manufacture high-power devices; 6H-SiC is the most stable and can be used to manufacture optoelectronic devices; 3C-SiC, because of its structure similar to GaN, can be used to produce GaN epitaxial layers and manufacture SiC-GaN RF devices. 3C-SiC is also commonly referred to as β-SiC. An important use of β-SiC is as a thin film and coating material. Therefore, β-SiC is currently the main material for coating.