- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China alumina al2o3 Manufacturers, Suppliers, Factory

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for alumina al2o3,Grinding Chuck,alumina ceramic,alumina oxide,white alumina, Top quality, timely company and Aggressive cost, all win us a superior fame in xxx field despite the international intense competition.

alumina al2o3, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Hot Products

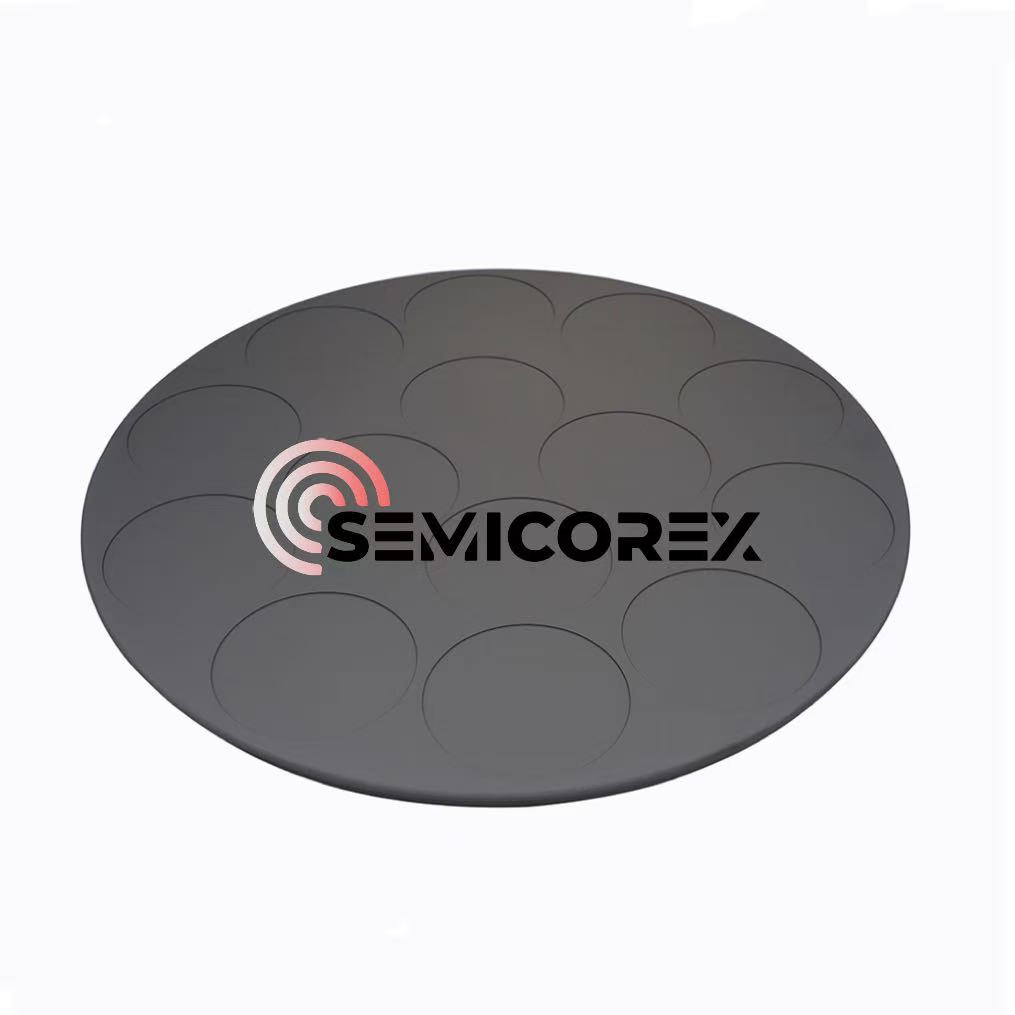

PSS Etching Carrier Tray for LED

At Semicorex, we have designed the PSS Etching Carrier Tray for LED specifically for the harsh environments required for epitaxial growth and wafer handling processes. Our ultra-pure graphite carrier is ideal for thin-film deposition phases like MOCVD, epitaxy susceptors, pancake or satellite platforms, and wafer handling processing such as etching. The SiC coated carrier has high heat and corrosion resistance, excellent heat distribution properties, and a high thermal conductivity. Our PSS Etching Carrier Tray for LED is cost-effective and offer a good price advantage. We cater to many European and American markets and look forward to becoming your long-term partner in China.Wafer Holder for ICP Etching Process

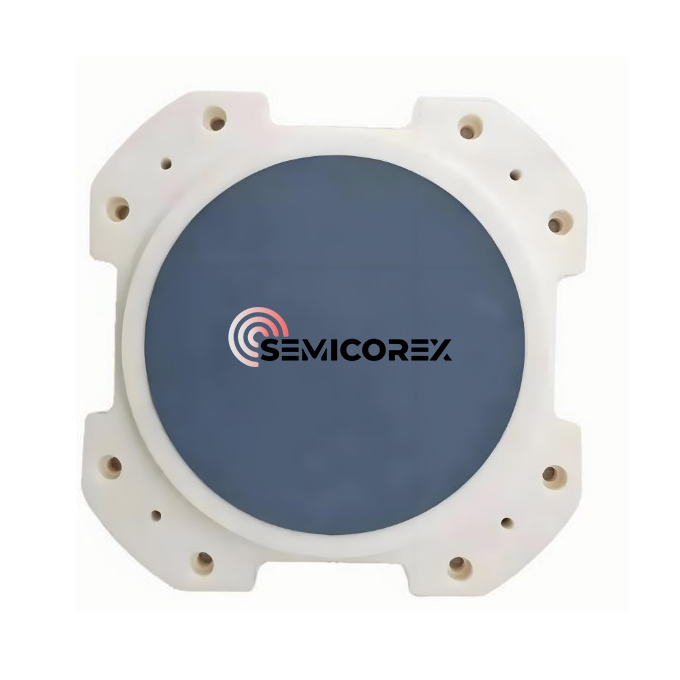

Semicorex's Wafer Holder for ICP Etching Process is the perfect choice for demanding wafer handling and thin film deposition processes. Our product boasts superior heat and corrosion resistance, even thermal uniformity, and optimal laminar gas flow patterns for consistent and reliable results.MOCVD Wafer Carriers for Semiconductor Industry

Semicorex MOCVD Wafer Carriers for Semiconductor Industry is a top-of-the-line carrier designed for use in the semiconductor industry. Its high-purity material ensures even thermal profile and laminar gas flow pattern, delivering high-quality wafers.TaC-Coating Crucible

Semicorex TaC-Coating Crucible has emerged as an essential tool in the pursuit of high-quality semiconductor crystals, enabling advancements in material science and device performance. The TaC-Coating Crucible's unique combination of properties makes them ideally suited for the demanding environments of crystal growth processes, offering distinct advantages over traditional materials.**Graphite Carrier for Epitaxial Reactors

Semicorex Graphite Carrier for Epitaxial Reactors is a SiC coated graphite component with precision micro-holes for gas flow, optimized for high-performance epitaxial deposition. Choose Semicorex for superior coating technology, customization flexibility, and industry-trusted quality.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.

Related Search

al2o3 ceramic;alumina oxide;alumina al2o3;wafer handling;wafer handling tweezers;wafer handling tools;semiconductor manufacturing;alumina ceramic material;fine ceramics;white aluminaalumina oxide ceramic;ceramic flange;alumina al2o3;flange;white alumina;alumina ceramic material;alumina machining;alumina aluminium oxide;high purity alumina;alumina material;