- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Silicon Carbide (SiC) Manufacturers, Suppliers, Factory

Silicon carbide ceramic (SiC) is an advanced ceramic material containing silicon and carbon. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics. Semicorex supplies custom silicon carbide ceramics as your requiring.

Applications

With silicon carbide ceramics the material properties remain constant up to temperatures above 1,400°C. The high Young’s modulus > 400 GPa ensures excellent dimensional stability.

A typical application for silicon carbide components is dynamic sealing technology using friction bearings and mechanical seals, for instance in pumps and drive systems.

With the advanced properties, silicon carbide ceramics are also ideal for use in the semiconductor industry.

Wafer Boats →

Semicorex Wafer Boat is made of sintered silicon carbide ceramic, which has good resistance to corrosion and excellent resistance to high temperatures and thermal shock. Advanced ceramics deliver excellent thermal resistance and plasma durability while mitigating particles and contaminants for high-capacity wafer carriers.

Reaction sintered silicon carbide

Compared with other sintering processes, the size change of reaction sintering during the densification process is small, and products with precise dimensions can be produced. However, the presence of a large amount of SiC in the sintered body makes the high temperature performance of reaction sintered SiC ceramics worse.

Pressureless sintered silicon carbide

Pressureless sintered silicon carbide (SSiC) is a particularly light and at the same time hard high-performance ceramic. SSiC is characterized by high strength, which remains almost constant even at extreme temperatures.

Recrystal silicon carbide

Recrystallized silicon carbide(RSiC) are next generation materials formed by mixing high-purity silicon carbide coarse powder and high-activity silicon carbide fine powder, and after grouting, vacuum sintering at 2450 ° C to recrystallize.

- View as

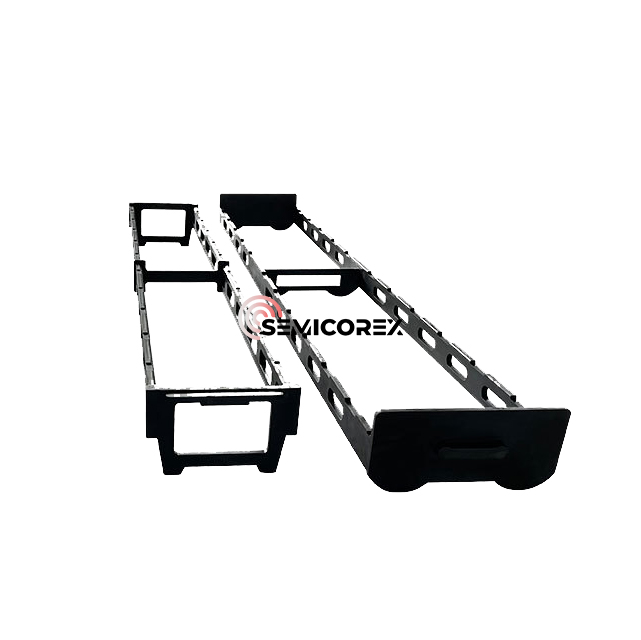

SiC Boat Holders

Semicorex SiC Boat Holders are essential structural components that ensure precise and reliable wafer positioning in semiconductor thermal processing. Choose Semicorex for unmatched quality, technical expertise, and a commitment to advancing high-purity SiC solutions in semiconductor manufacturing.*

Read MoreSend InquiryWafer Boats

Semicorex wafer boats are precision-engineered ceramic carriers designed for high-temperature wafer processing in semiconductor manufacturing. Choose Semicorex for its unmatched material purity, advanced fabrication technology, and commitment to quality that ensures consistent performance in the most demanding cleanroom environments.*

Read MoreSend InquirySiC Tubes

Semicorex SiC Tubes are silicon carbide furnace tubes designed for semiconductor high-temperature processes, with excellent thermal stability and chemical corrosion resistance. Choosing Semicorex high-purity raw materials, precision manufacturing processes and long-term reliability guarantees to provide solid support for your semiconductor manufacturing process.*

Read MoreSend InquirySiC Ceramic Boats

Semicorex SiC ceramic boats provide the optimal combination of purity, strength, thermal resistance, and dimensional accuracy required for the rigorous demands of modern semiconductor wafer processing. *

Read MoreSend InquirySiC Robot hands

Semicorex SiC Robot Hands are high-precision, ultra-clean end-effectors designed for safe and reliable wafer transfer in semiconductor manufacturing.Choose Semicorex for industry-leading expertise in advanced ceramics, delivering superior performance, purity, and customization trusted by top semiconductor fabs worldwide.*

Read MoreSend InquirySiC Edge Ring

Semicorex CVD SiC Edge Ring is a high-performance plasma-facing component designed to enhance etching uniformity and protect wafer edges in semiconductor manufacturing. Choose Semicorex for unmatched material purity, precision engineering, and proven reliability in advanced plasma process environments.*

Read MoreSend Inquiry