- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

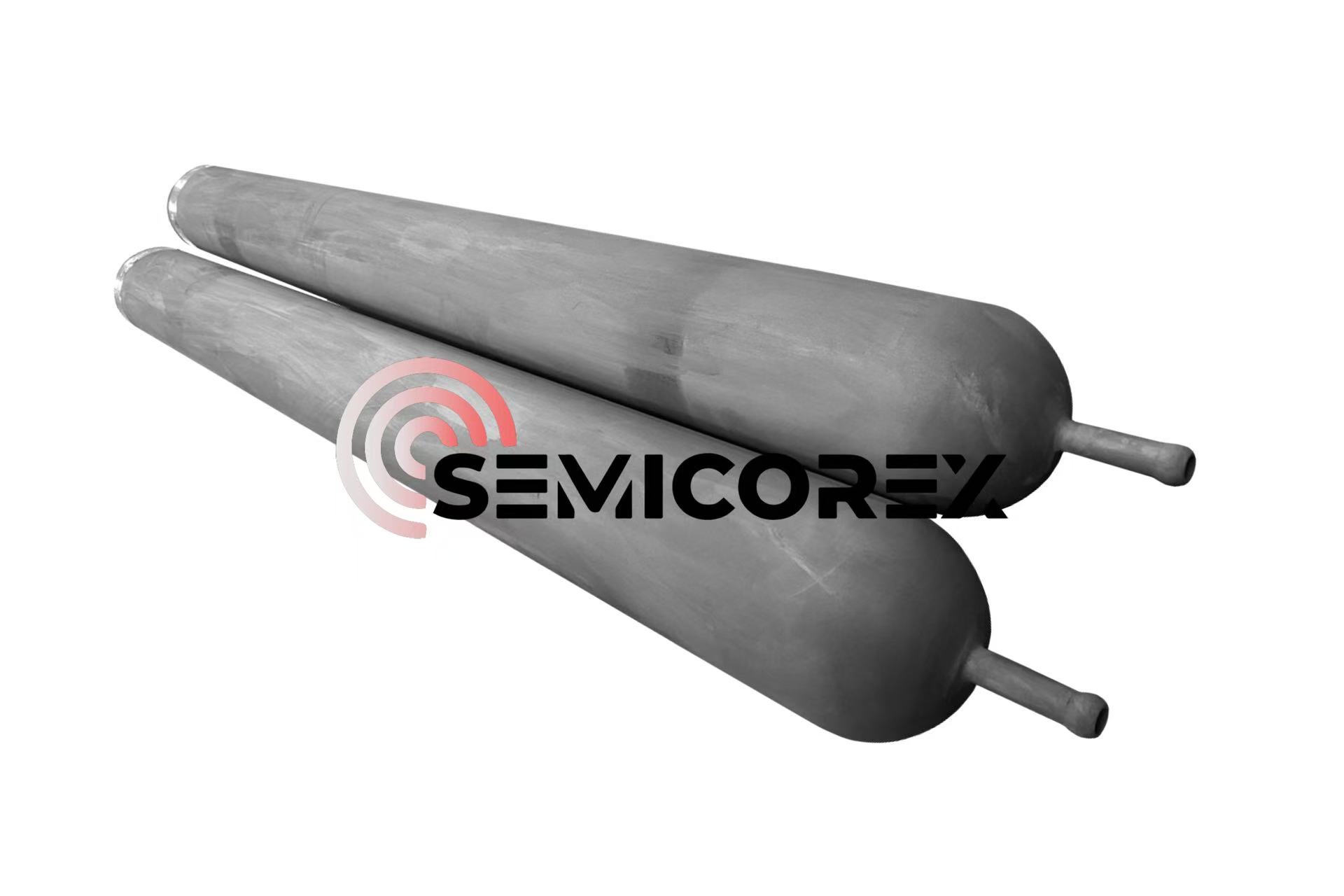

SIC Horizontal Furnace Tubes

SIC horizontal furnace tubes are the horizontally placed tubular reaction and heating containers that provides the stable high-temperature processing environments for semiconductor materials. With their unparalleled material properties, precision design, and enduring service life, Semicorex's SIC horizontal furnace tubes are the optimal solutions for improving yield and product quality.

Send Inquiry

SIC horizontal furnace tubes are the indispensable carriers of the furnace system, commonly located in the core heating area of semiconductor manufacturing or photovoltaic production equipment. They work together with the heating elements, the temperature control systems, the gas control systems and the wafer boats to form the complete furnace system.

In the actual operation, SIC horizontal furnace tubes are heated by the heating elements, which uniformly transfer the heat into the furnace tubes with the help of the excellent thermal conductivity of silicon carbide materials. Meanwhile, specific process gases (such as oxygen, nitrogen, doping gases, etc.) are introduced into the furnace tube. Under the effect of this high-temperature gas atmosphere, semiconductor materials inside the furnace will undergo chemical reactions or physical changes, ultimately achieving material modification, doping, or structural optimization.

Semicorex’s SIC horizontal furnace tubes deliver remarkable mechanical strength and hardness, which plays a significant role in applications involving large-volume wafer handling and processing. SIC horizontal furnace tubes are able to provide stable support for wafers in heat treatment processes such as oxidation, diffusion, and annealing, ensuring that the wafers are in the right position during high-temperature processing and avoiding displacement or deformation caused by thermal stress.

Semicorex’s SIC horizontal furnace tubes are manufactured from high-purity silicon carbide ceramics with ultra-low impurity content, followed by the deposition of a CVD silicon carbide coating on their surface. This manufacturing method adds a protective layer to SIC horizontal furnace tubes, which enables them to operate stably in the demanding high-temperature and corrosive environments over time. This corrosion resistance performance of SIC horizontal furnace tubes improves the efficiency of semiconductor wafer manufacturing by effectively lowering the risk of corrosion-related component damage and reducing the need for frequent replacements and maintenance.

With so many superior properties, Semicorex’s SIC horizontal furnace tubes are widely used in many high-temperature processing processes in the photovoltaic and semiconductor industries such as oxidation process, diffusion process, annealing process and low pressure chemical vapor deposition.