- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

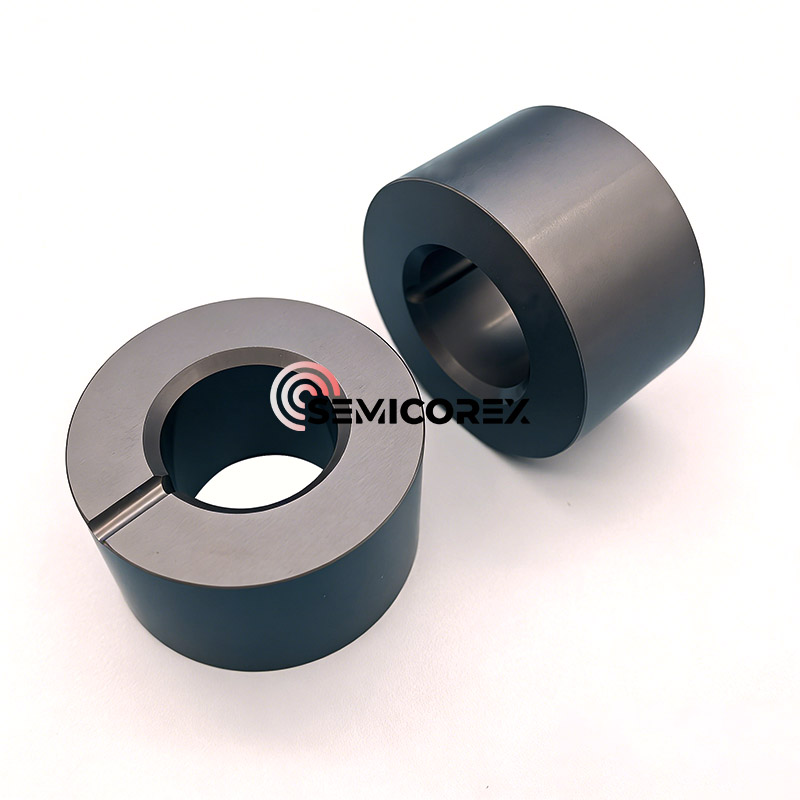

SiC Seal Rings

Semicorex SiC Seal Rings are made by high-quality Silicon Carbide ceramic, are suitable for wide applications in industry. Semicorex provides high precious machining ceramic products, and is looking for a long-term relationship with the customers.*

Send Inquiry

Semicorex SiC Seal Rings are made from high-purity silicon carbide and designed for tough industrial settings. They offer strong wear resistance, chemical durability, and thermal stability. Thanks to their hardness and low friction, these rings are a top choice for mechanical seals in pumps, compressors, mixers, and other rotating equipment. Their reliability and long service life help prevent leaks, avoid contamination, and keep equipment running smoothly.

SiC Seal Rings use silicon carbide, a ceramic known for being both strong and lightweight. Its hardness is only lower than diamond. It can keep the good wear and abrasion resistance even under strict condition. It means the seal surface can stay smooth and flat by a long time, to reduce the risk of seal failure, and reduce the maintenance work. The material’s rigidity also can keep the seal rings from deforming under the pressure.

SiC Seal Rings handle heat very well, making them suitable for high-temperature applications and systems with rapid temperature fluctuations. Silicon carbide remains stable across a broad temperature range and helps transfer heat away from the seal. This reduces the risk of thermal cracks, prevents overheating, and extends the lifespan of the seal and nearby components. In industries that use hot oils, steam, chemicals, or fast processing, SiC’s thermal durability offers a clear benefit over materials like carbon graphite, tungsten carbide, or standard ceramics.

Silicon carbide is also highly resistant to chemicals. SiC Seal Rings do not corrode when exposed to acids, alkalis, solvents, saltwater, or harsh chemicals, making them excellent for chemical processing, petrochemical plants, wastewater treatment, marine environments, and pharmaceutical manufacturing. Because the material is inert, it does not react with process fluids, helping to keep both the seal and the media pure. This is especially critical for processes requiring strict contamination control or those exposed to long-term corrosive conditions.

SiC Seal Rings are manufactured with high precision, resulting in excellent surface quality, flatness, and accuracy—essential factors for effective sealing. Advanced machining and finishing ensure the rings fit well within seal assemblies and maintain steady contact during operation. Whether used as stationary or rotating components, silicon carbide rings operate smoothly with minimal friction, which conserves energy and reduces noise. They are available in reaction-bonded (RB-SiC) or SSiC forms to meet various requirements for strength, purity, and performance.

SiC seal rings are widely applied in oil gas, chemical industry, power generation, pharmacy, food production, mining, water processing, and etc. They can instantly stand under high-temperature, high-pressure and corrosion, are the ideal choice for the key equipment that high cost for stopping. Using SiC seal rings is good for intending the lifespan, improving efficiency, and lower maintenance costs. In current industry environment, the properties, safety and durability are the most important, SiC seal rings are a great solutions to meet the strict working environment.