- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

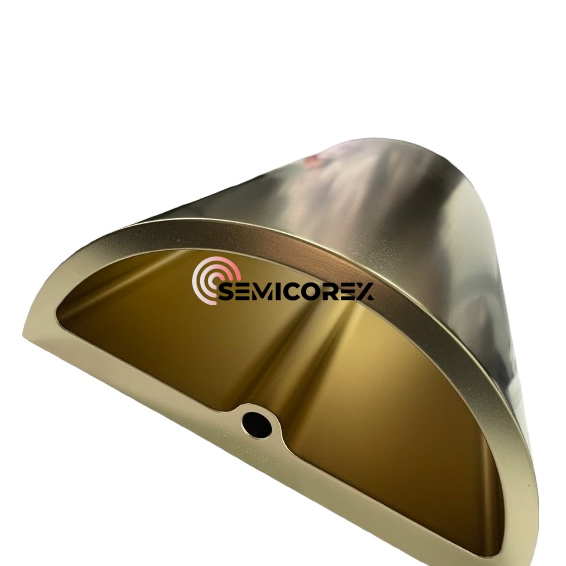

China TaC Manufacturers, Suppliers, Factory

Dependable high-quality and good credit rating standing are our principles, which will help us at a top-ranking position. Adhering into the tenet of "quality first, consumer supreme" for TaC,CVD COATING,Tantalum Carbide,TaC Coatings,wafer suscecptor, To learn more about what we can do for you, contact us at any time. We look forward to establishing good and long-term business relationships with you.

TaC, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we present, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and comprehensive parameters and any other info weil be sent for you timely for your inquiries. So make sure you make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We have been confident that we are intending to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

Hot Products

SiC Coated Barrel Susceptor for LPE Epitaxial Growth

Semicorex SiC Coated Barrel Susceptor for LPE Epitaxial Growth is a high-performance product designed to provide consistent and reliable performance over an extended period. Its even thermal profile, laminar gas flow pattern, and prevention of contamination make it an ideal choice for the growth of high-quality epitaxial layers on wafer chips. Its customizability and cost-effectiveness make it a highly competitive product in the market.Deep-UV LED Epitaxial Susceptor

Semicorex is a large-scale manufacturer and supplier of Silicon Carbide Coated Graphite Susceptor in China. We have been manufacturer and supplier of Deep-UV LED Epitaxial Susceptor for many years. Our products have a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.Wafer Carrier for MOCVD

the Semicorex Wafer Carrier for MOCVD, Crafted for the precise needs of Metal Organic Chemical Vapor Deposition (MOCVD), emerges as an indispensable tool in the processing of single-crystal Si or SiC for high-scale integrated circuits. The Wafer Carrier for MOCVD composition boasts unparalleled purity, resistance to elevated temperatures and corrosive environments, and superior sealing properties to maintain a pristine atmosphere. We at Semicorex are dedicated to manufacturing and supplying high-performance Wafer Carriers for MOCVD that fuse quality with cost-efficiency.SiC-coated Wafer Disc

The Semicorex SiC-coated Wafer Disc represents a leading advancement in semiconductor manufacturing technology, playing an essential role in the complex process of fabricating semiconductors. Engineered with meticulous precision, this disc is crafted from superior SiC-coated graphite, delivering outstanding performance and durability for silicon epitaxy applications. We at Semicorex are dedicated to manufacturing and supplying high-performance SiC-coated Wafer Disc that fuse quality with cost-efficiency.Wafer Carriers with SiC Coating

The Semicorex Wafer Carriers with SiC Coating, an integral part of the epitaxial growth system, is distinguished by its exceptional purity, resistance to extreme temperatures, and robust sealing properties, serving as tray that is essential for the support and heating of semiconductor wafers during the critical phase of epitaxial layer deposition, thereby optimizing the overall performance of the MOCVD process. We at Semicorex are dedicated to manufacturing and supplying high-performance Wafer Carriers with SiC Coating that fuse quality with cost-efficiency.8-inch Waferholder Rings

Semicorex 8-inch Waferholder Rings are designed to provide precise wafer fixation and exceptional performance in aggressive thermal and chemical environments. Semicorex delivers application-specific engineering, tight dimensional control, and consistent SiC coating quality to meet the rigorous demands of advanced semiconductor processing.*