- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Silicon Carbide Coated Graphite Trays Manufacturers, Suppliers, Factory

We'll dedicate ourselves to offering our esteemed customers together with the most enthusiastically thoughtful solutions for Silicon Carbide Coated Graphite Trays,Silicon Carbide Semiconductor,SiC Silicon Carbide,Silicon Carbide Coating,SIC Epitaxy Process, "Passion, Honesty, Sound service, Keen cooperation and Development" are our objectives. We have been here anticipating good friends all over the environment!

Silicon Carbide Coated Graphite Trays, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

Hot Products

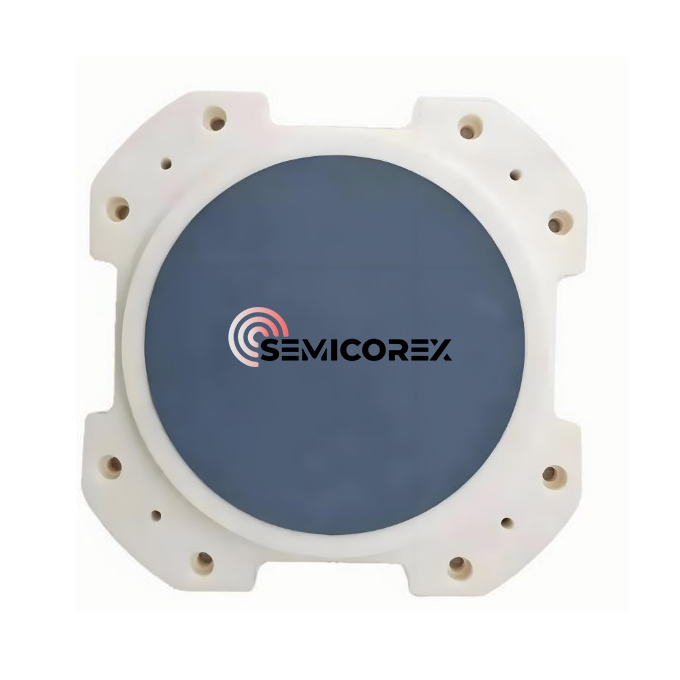

ICP Plasma Etching Plate

Semicorex's ICP Plasma Etching Plate provides superior heat and corrosion resistance for wafer handling and thin film deposition processes. Our product is engineered to withstand high temperatures and harsh chemical cleaning, ensuring durability and longevity. With a clean and smooth surface, our carrier is perfect for handling pristine wafers.MOCVD Wafer Carriers for Semiconductor Industry

Semicorex MOCVD Wafer Carriers for Semiconductor Industry is a top-of-the-line carrier designed for use in the semiconductor industry. Its high-purity material ensures even thermal profile and laminar gas flow pattern, delivering high-quality wafers.TaC Coated Graphite Susceptor

Semicorex cutting-edge TaC Coated Graphite Susceptor, a revolutionary component designed to elevate your wafer epitaxial process to new heights of efficiency and precision. Crafted with unparalleled expertise and utilizing state-of-the-art technology, Semicorex TaC Coated Graphite Susceptor is engineered to meet the exacting demands of semiconductor manufacturing.TaC Coating Ring

Semicorex TaC Coating Ring stands as a pivotal component in the realm of monocrystal growth within the thermal field. Crafted with precision and innovation, this specialized guide ring plays a crucial role in the intricate process of monocrystalline material production. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Planetary Susceptor

Semicorex Planetary Susceptor is a high-purity graphite component with a SiC coating, designed for Aixtron G5+ reactors to ensure uniform heat distribution, chemical resistance, and high-precision epitaxial layer growth.*Al2O3 Vacuum Chucks

Semicorex Al2O3 Vacuum Chucks are microporous ceramic adsorption fixture made from black alumina with a porosity of 35–40%, specifically designed for wafer handling in semiconductor applications. Choosing Semicorex means benefiting from advanced ceramic technology, precision engineering, and reliable product quality that ensure stable performance in demanding cleanroom environments.*