- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China rapid thermal annealing Manufacturers, Suppliers, Factory

We've got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for rapid thermal annealing,lpe sic epitaxy,asm epitaxy,epitaxy of semiconductors,epi wafer, High quality, timely service and Aggressive rate, all earn us a excellent fame in xxx field despite the international intense competition.

rapid thermal annealing, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Hot Products

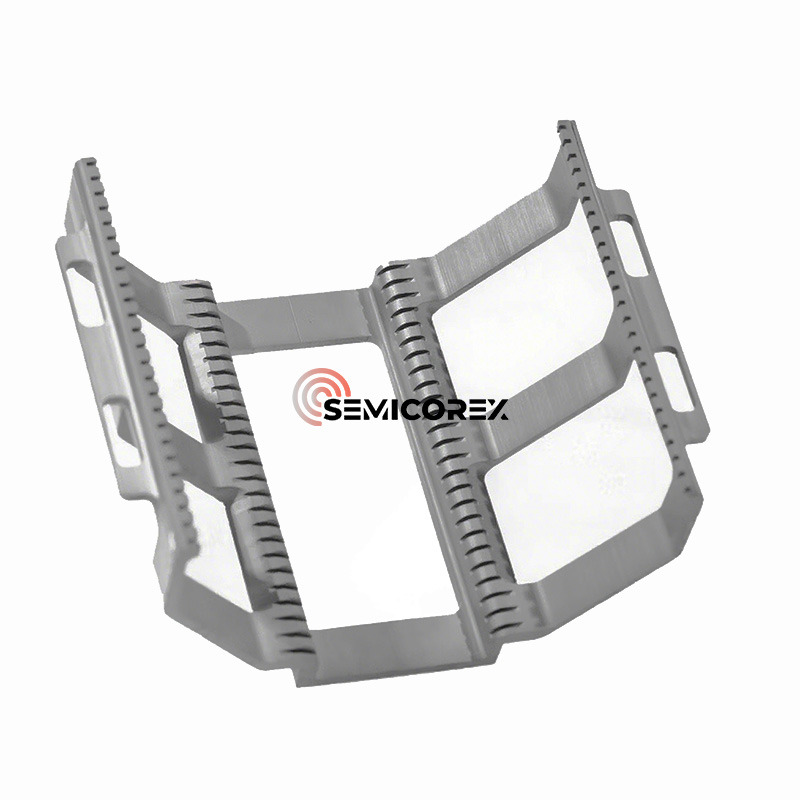

Wafer Carrier Tray

Semicorex provides semiconductor-grade ceramics for your OEM semi fabrication tools and wafer handling components focusing on silicon carbide layers in semiconductor industries. We have been manufacturer and supplier of Wafer Carrier Tray for many years. Our Wafer Carrier Tray has a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.PBN/PG Heaters

Semicorex PBN/PG Heaters (Pyrolytic Boron Nitride/Pyrolytic Graphite) are engineered from advanced Boron Nitride ceramic materials, meticulously crafted to withstand extreme temperatures exceeding 1700°C. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Shower Head

Semicorex SiC Shower Head is an essential component in the epitaxial growth process, specifically designed to enhance the uniformity and efficiency of thin film deposition on semiconductor wafers. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Rigid Graphite Felt

Semicorex Rigid Graphite Felt is a high-performance thermal insulation material made from PAN-based and viscose-based carbon fiber, widely used in high-temperature industrial furnaces. Choose Semicorex for its advanced manufacturing processes and proven expertise in delivering durable and reliable solutions for demanding semiconductor applications.*Horizontal Chamber Furnace SiC boats

Semicorex Horizontal Chamber Furnace SiC Boats are high-purity silicon carbide carrier designed for secure wafer holding during high-temperature horizontal furnace processing. Choosing Semicorex means benefiting from precise engineering, exceptional durability, and superior thermal performance for consistent, high-yield production.*SiC Lid

Semicorex SiC Lid is a high-purity silicon carbide component engineered for extreme semiconductor processing environments. Choosing Semicorex means ensuring unmatched material quality, precision engineering, and custom solutions trusted by leading semiconductor manufacturers worldwide.*