- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

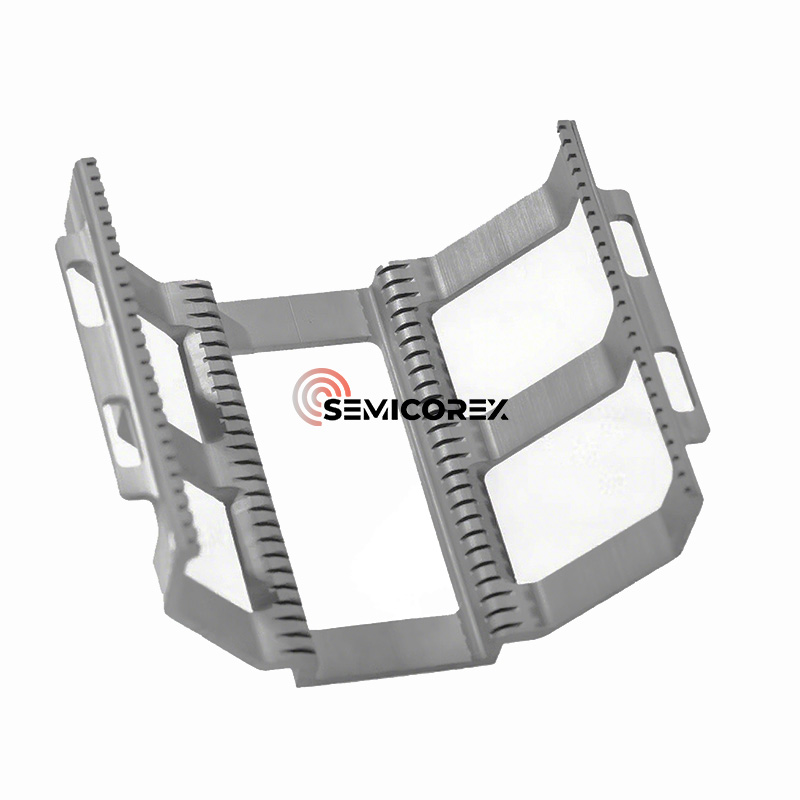

Horizontal Chamber Furnace SiC boats

Semicorex Horizontal Chamber Furnace SiC Boats are high-purity silicon carbide carrier designed for secure wafer holding during high-temperature horizontal furnace processing. Choosing Semicorex means benefiting from precise engineering, exceptional durability, and superior thermal performance for consistent, high-yield production.*

Send Inquiry

Semicorex Horizontal Chamber Furnace SiC Boats are a highly-engineered part that holds and carries wafers or substrates while they are subjected to high-temperature thermal processing in a horizontal chamber furnace. The wafer boat is made of high-purity SiC bonded silicon carbide (SiC), which provides the unique combination of strength, thermal stability, and high chemical resistance that are demanded in semiconductor, photovoltaic, and advanced ceramics processes. The wafer boat also acts as a rigid structure to hold wafers in position, the dimensional stability and the precision of the wafers will not be lost by extended exposure to the extreme process temperatures.

The superior properties of silicon carbide provide the Horizontal Chamber Furnace SiC Boats a superior performance advantage as compared to typical materials for wafer boats such as quartz or alumina. They can better withstand infrequent short-duration heating and cooling cycles owing to their high melting point, thermal shock resistance, and mechanical strength, regardless of the speed of heating and cooling or extremes of the thermal cycle. Since a horizontal furnace relies entirely on the consistency of the wafers' positions and the exposure of process conditions, proper alignment of wafers provides for consistent process yield and repeatability. The low coefficient of thermal expansion means the boat will not distort over its life and provide retained shape and spacing of the wafers.

The fine-grained, dense structure of recrystallized SiC provides remarkable resistance to oxidation, corrosion, and contamination by process gases and byproducts. This makes the boat especially advantageous for processes in aggressive atmospheres such as diffusion, oxidation, LPCVD, and annealing. The high chemical inertness of SiC avoids reactions with the wafer surfaces, thus preserving product purity and minimizing particulate generation in the furnace. SiC boats can help manufacturers who need to meet stringent cleanliness demands, providing cleaner processing environments and improved wafer quality.

These boats can be produced with various complex geometries and part-specific dimensions with precision machining and forming techniques. The designs generally use multiple parallel slots/grooves to hold the wafers securely in a horizontal orientation and uniformly expose the whole wafer surface to thermal conditions. Slot-to-slot spacing and angles can also be optimized to fit wafers of other diameters, such as 150 mm, 200 mm, or 300 mm, and direct airflow during processing effects while still achieving temperature uniformity for processing.

Not only can the Horizontal Chamber Furnace SiC Boats be designed in standard departures, but they can be designed to work with automated wafer loaders, resulting in a seamless integration into modern high-throughput production lines. The robust design will also make the boats less likely to chip or break during handling and reduce downtime and costs for replacements.

The thermal conductivity of silicon carbide represents another key advantage that facilitates efficient heat transfer between the wafers and the furnace environment. The advantage is that manufacturers are able to achieve more uniform processing conditions and shorten cycle times, which can increase production efficiency. The SiC boats provide consistent and repeatable results whether they are used for semiconductor wafer fabrication, solar cell manufacturing, or other advanced materials processing at elevated temperatures.

In summary, the Horizontal Chamber Furnace SiC Boats are a key component for manufacturers looking to produce wafers with a high-performance, long-lasting and contamination-resistant wafer carriers. It has a mechanical strength, thermal stability and chemical inertness that is unequaled in horizontal furnaces applications. By choosing silicon carbide boats, operators can leverage better process control, higher yields, and minimize operational interruptions due to maintenance. Overall it provides for more efficient, cost effective productions.