- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

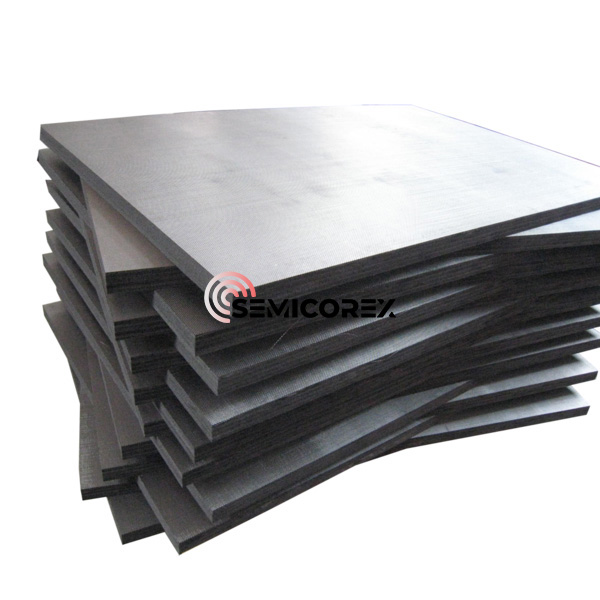

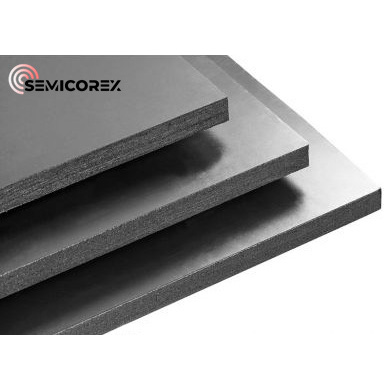

Rigid Graphite Felt

Semicorex Rigid Graphite Felt is a high-performance thermal insulation material made from PAN-based and viscose-based carbon fiber, widely used in high-temperature industrial furnaces. Choose Semicorex for its advanced manufacturing processes and proven expertise in delivering durable and reliable solutions for demanding semiconductor applications.*

Send Inquiry

Rigid Graphite Felt can be formed by soft felt lamination curing and wet forming. The common lamination method for making carbon fiber graphite hard felt uses soft felt as raw material. The production process starts with cutting: cutting multiple pieces of blanks slightly larger than the final hard felt size from the soft felt. After cutting, it is impregnated with resin and other bonding materials, and the impregnated blanks are stacked in multiple layers according to the required hard felt thickness.

The impregnation in soft felt production is mainly impregnation with catalysts to make viscose fibers more stable in subsequent heat treatment; while the impregnation of Rigid Graphite Felt is mainly impregnation with thermosetting resin. In the subsequent heating and curing process, the liquid resin solidifies, and the multiple layers of soft felt are tightly combined with the resin to form.

Resin + carbon fiber graphite soft felt allows the material to achieve the effect of "1+1>2" in some properties. After heating and curing, the multi-layered soft felt impregnated with resin can no longer be rolled up like soft felt, and the density and compressive strength of the material are also increased.

During the PVT growth of single crystals, carbon fiber felt plays a role in heat preservation. The purity of Rigid Graphite Felt is crucial to the successful growth of SiC crystals. Impurities in the insulation felt material are one of the sources of impurity contamination during the growth process. The content of key impurity elements in carbon fiber felt is controlled below 10-6, and the total ash content must be strictly controlled. According to the patent, it adopts different high-temperature multi-stage purification treatment methods, using multiple gas circulation steps in each stage to convert high-melting point impurities into low-melting point compounds, and discharge impurity gases, and finally obtain high-purity carbon fiber felt, whose ash content is less than 20mg·kg, and Al, B, Fe, V are less than 0.1mg·kg.

Rigid Graphite Felt also has key technologies for flow field uniformity control, including temperature field and gas flow field uniformity control. The temperature field is uniformized in the single crystal furnace by designing temperature compensation areas, multi-zone independent temperature control, and changing the shape and layout of the heater.

![]()

![]()

![]()