- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Led Wafer Manufacturers, Suppliers, Factory

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for Led Wafer,Gan Wafer,MOCVD Led,Aln Ceramic Substrate,Graphite Plate, We fully welcome shoppers from all around the world to ascertain stable and mutually effective enterprise interactions, to have a dazzling long run jointly.

Led Wafer, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

Hot Products

ICP Plasma Etching System

Semicorex's SiC Coated carrier for ICP Plasma Etching System is a reliable and cost-effective solution for high-temperature wafer handling processes such as epitaxy and MOCVD. Our carriers feature a fine SiC crystal coating that provides superior heat resistance, even thermal uniformity, and durable chemical resistance.RTP Carrier for MOCVD Epitaxial Growth

Semicorex RTP Carrier for MOCVD Epitaxial Growth is ideal for semiconductor wafer processing applications, including epitaxial growth and wafer handling processing. Carbon graphite susceptors and quartz crucibles are processed by MOCVD on the surface of graphite, ceramics, etc. Our products have a good price advantage and cover many of the European and American markets. We look forward to becoming your long-term partner in China.Silicon Carbide Coating Graphite Susceptor for MOCVD

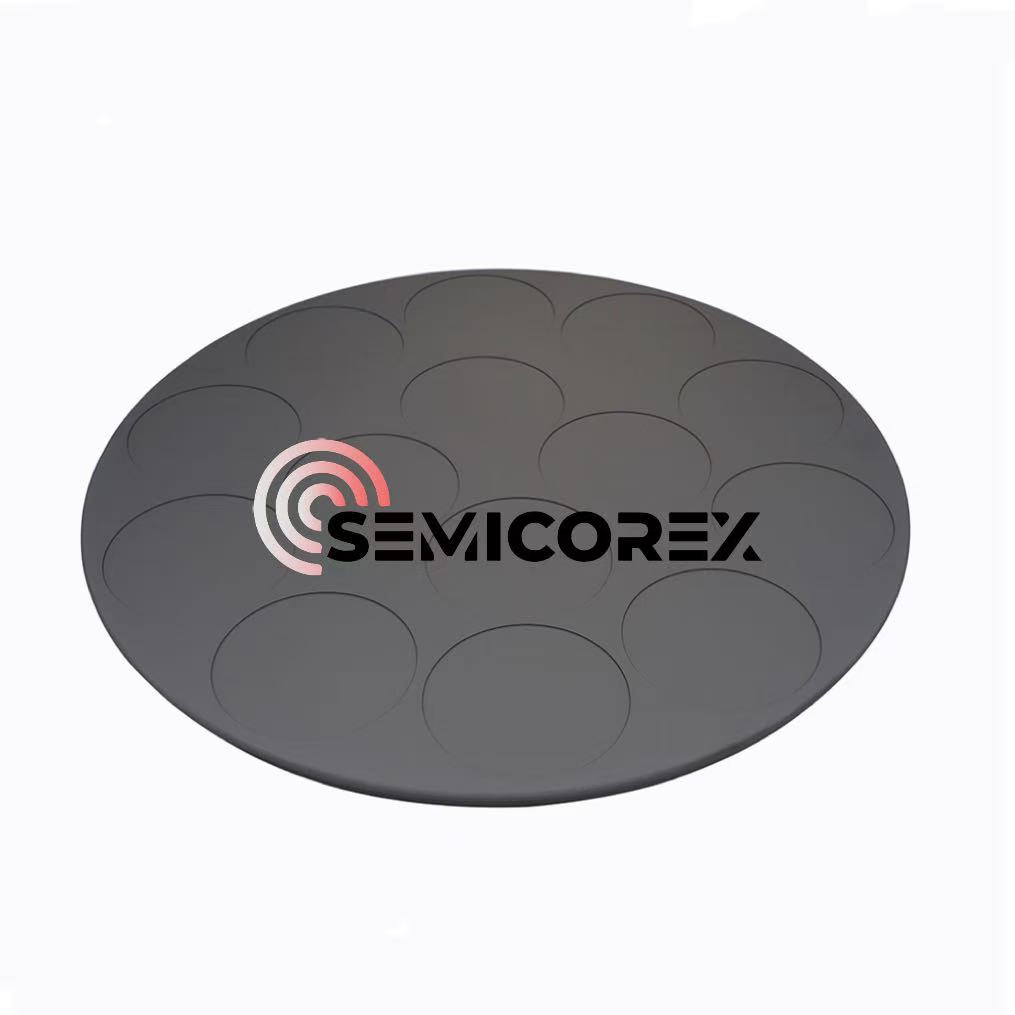

Semicorex is a trusted supplier and manufacturer of silicon carbide coating graphite susceptor for MOCVD. Our product is specially designed to cater to the needs of the semiconductor industry in growing the epitaxial layer on the wafer chip. The product is used as the center plate in MOCVD, with a gear or ring-shaped design. It has high heat and corrosion resistance, making it ideal for use in extreme environments.CVD SiC Coated Barrel Susceptor

Semicorex CVD SiC Coated Barrel Susceptor is a meticulously engineered component tailored for advanced semiconductor manufacturing processes, particularly epitaxy. Our products have a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.SiC Coated Waferholder

Semicorex SiC Coated Waferholder is a high-performance component designed for the precise placement and handling of SiC wafers during epitaxy processes. Choose Semicorex for its commitment to delivering advanced, reliable materials that enhance the efficiency and quality of semiconductor manufacturing.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.