- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Vacuum Chucks

Semicorex Vacuum Chucks are the perfect solution for wafer handling in semiconductor and precision industries. With a variety of base material options, ceramic plate customizations, and precise flatness control, our vacuum chucks ensure reliable wafer stability and excellent process results. Designed to meet the stringent demands of modern semiconductor manufacturing, these chucks deliver unparalleled performance, ensuring that your processes remain efficient and cost-effective.*

Send Inquiry

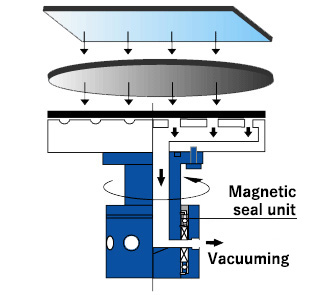

Semicorex Vacuum Chucks are precision-engineered solutions designed to provide secure, stable, and efficient handling of wafers in semiconductor manufacturing processes. These vacuum chucks are mainly used for holding wafers during various processing stages, ensuring minimal damage to the wafers, maximum stability, and enhanced process efficiency. Our vacuum chucks are available in a variety of base materials and ceramic plates, offering tailored solutions to meet the diverse needs of the semiconductor industry and other precision industries.

Key Features and Materials

Semicorex offers a range of base material options for the vacuum chuck, allowing customization based on specific application requirements:

Base Materials:

- SUS430: A stainless steel base material known for its strength and corrosion resistance, providing excellent mechanical stability.

- Aluminum Alloy 6061: Lightweight yet strong, this aluminum base offers high corrosion resistance and is ideal for applications where weight is a concern.

- Alumina Ceramic (99% Alumina): Offers high thermal stability and wear resistance. It is an excellent choice for high-precision environments where thermal resistance is critical.

- Granite: Known for its rigidity and superior vibration-damping properties, granite offers excellent stability and precision during wafer handling.

- Silicon Carbide (SiC) Ceramic: Offers high hardness, thermal conductivity, and resistance to chemical corrosion. It is perfect for high-temperature and aggressive environments.

Ceramic Plates:

Alumina (Al₂O₃): Alumina plates are known for their high electrical insulation properties, wear resistance, and high temperature stability. They are suitable for environments where minimal contamination and high performance are crucial.

Silicon Carbide (SiC): SiC ceramic plates provide exceptional hardness, high thermal conductivity, and stability at elevated temperatures, making them ideal for advanced wafer handling processes in semiconductor production.

Flatness Precision and Material Selection

The flatness of the chuck's surface is a critical factor in ensuring proper wafer handling and optimal process results. The material choice impacts the flatness precision, as well as the overall weight and thermal properties of the vacuum chuck.

Flatness Precision:

Aluminum Alloy 6061: Provides excellent flatness with precision, making it a popular choice for less demanding wafer handling tasks.

SUS430: While offering solid mechanical stability, SUS430 has a slightly lower flatness precision than aluminum alloy.

Alumina Ceramic (99% Alumina): Offers the best flatness precision due to its high dimensional stability under high temperatures and mechanical stress.

Granite: Known for its stability, granite provides precise flatness, particularly in vibration-sensitive environments.

Silicon Carbide Ceramic: Provides outstanding flatness precision and is ideal for high-precision wafer handling in high-temperature applications.

Weight Considerations

The weight of the vacuum chuck is another important factor, particularly for applications where the chuck's ease of handling and manipulation is a key consideration.

Aluminum Alloy 6061: The lightest material, making it ideal for applications requiring reduced weight without sacrificing strength.

Granite: Heavier than aluminum, granite's weight provides additional stability, especially in processes where vibration damping is crucial.

Silicon Carbide Ceramic (SiC): While heavier than aluminum, SiC's exceptional strength and thermal stability make it the material of choice for demanding applications.

Alumina Ceramic (99% Alumina): Similar in weight to granite, alumina provides a balance of stability, weight, and high-temperature resistance.

Customization Options

Our vacuum chucks can be tailored with varying pore sizes in the ceramic plates to suit specific application needs. The ceramic plates can also be customized with different colors, allowing for easy identification of different chucks used in various processes.

Applications

Semicorex Vacuum Chucks are indispensable tools in a wide range of semiconductor manufacturing processes, including:

- Wafer Handling: Securing wafers during various processes such as etching, deposition, and testing.

- Precision Manufacturing: Ideal for industries requiring stable, contamination-free wafer holding with minimal damage to delicate materials.

- High-Temperature Processes: Particularly beneficial for high-temperature processes where materials like SiC and alumina are critical for their thermal stability.

Semicorex Vacuum Chucks are designed for precision, durability, and versatility. We offer a selection of high-quality base materials paired with customizable ceramic plates, allowing us to create tailored solutions for various manufacturing processes. Whether you need lightweight, high-precision wafers or materials that can withstand extreme temperatures, our vacuum chucks deliver the reliability and performance you need. By choosing Semicorex, you are investing in a high-performance product supported by exceptional engineering and manufacturing expertise.