- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

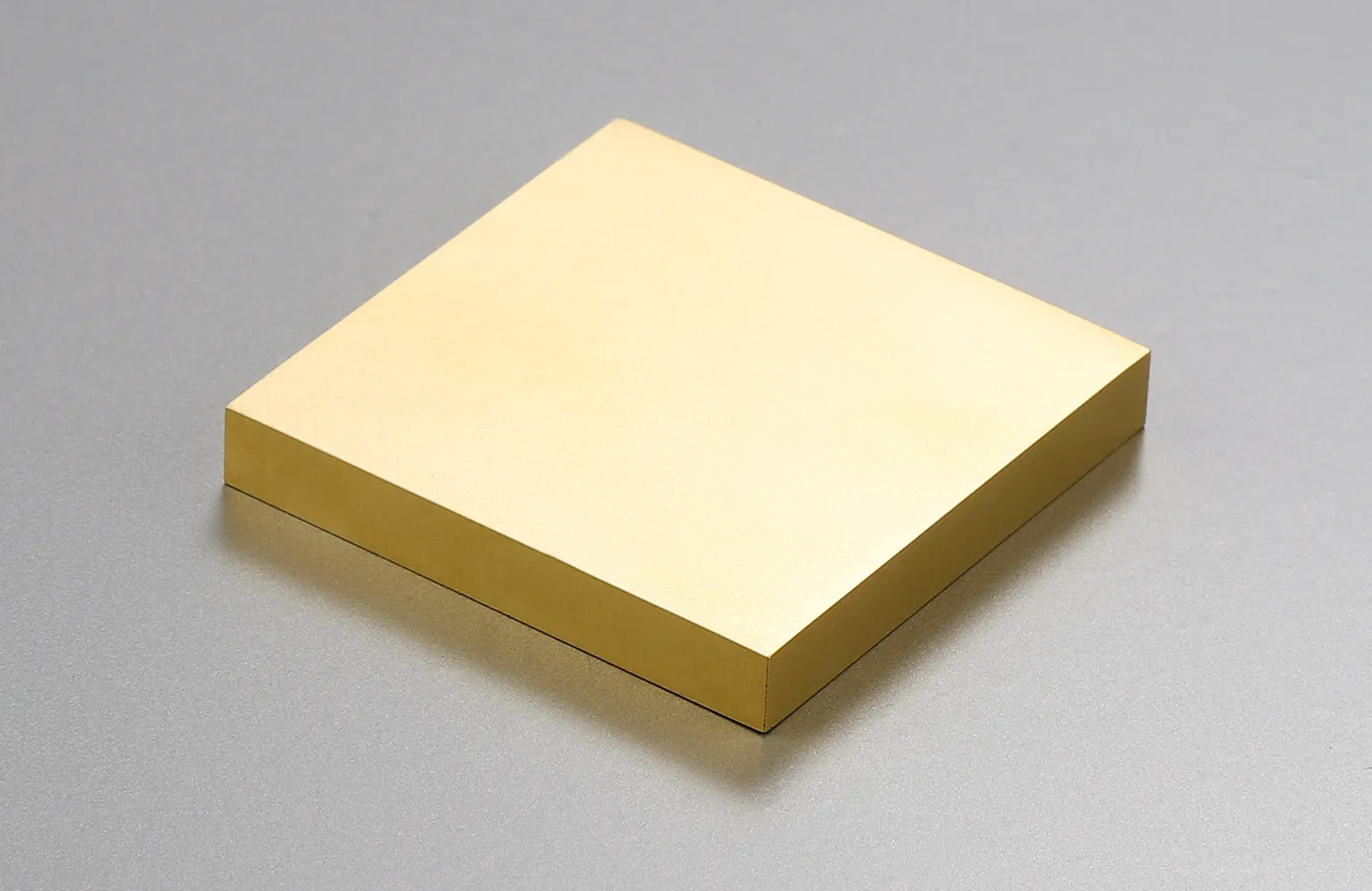

TaC Coating Pedestal Supporter

Semicorex TaC Coating Pedestal Supporter is a critical component designed for epitaxial growth systems, specifically tailored for supporting reactor pedestals and optimizing process gas flow distribution. Semicorex delivers a high-performance, precision-engineered solution that combines superior structural integrity, thermal stability, and chemical resistance—ensuring consistent, reliable performance in advanced epitaxy applications.*

Send Inquiry

Semicorex TaC Coating Pedestal Supporter has a key role in mechanical support, but also in controlling the process flow. It is located underneath the main susceptor or wafer carrier when used in the reactor. It locks the rotating assembly into position, holds the thermal equilibrium in the pedestal, and manages a healthy gas flow beneath the wafer zone. The TaC Coating Pedestal Supporter is made for both functions, including a constructively made graphite base which is coated with a uniformly dense layer of tantalum carbide (TaC) by chemical vapor deposition (CVD).

Tantalum Carbide is one of the most refractory and chemically inert materials available, with a melting point above 3800 °C and great resistance to corrosion and erosion. When CVD is employed to produce TaC coatings, the end result is a smooth, dense coating which protects the graphit substrate from high temperature oxidation, ammonia corrosion, and metal-organic precursor reaction. Under lengthy exposure to corrosive gases or extreme thermal cycling associated with epitaxial processes, the pedestal supporter endures, maintaining structural and chemical stability.

Performing multiple critical functions, the CVD TaC coating acts as a protective barrier, keeping any potential carbon contamination from the graphite coating and substrate from entering the reactor environment or impacting the wafer. Second, it provides chemical inertness, maintaining a clean and stable surface in both oxidizing and reducing atmospheres. This prevents unwanted reactions between the process gases and the reactor hardware, ensuring that the gas-phase chemistry remains controlled and that film uniformity is preserved.

The significance of the pedestal supporter in gas flow control should be equally noted. A key aspect in the process of epitaxial deposition is to ensure uniformity of the process gases flowing over the entire surface of the wafer to achieve consistent layer growth. The TaC Coating Pedestal Supporter is precisely machined to control gas flow channels and geometries, which will help direct process gases smoothly and evenly into the reaction zone. By controlling the laminar flow, turbulence is minimized, dead zones are eliminated, and a more stable gas environment occurs. All this contributes to superior film thickness uniformity and better epitaxial quality.

The TaC coating provides high thermal conductivity and emissivity, which also allows the pedestal supporter to conduct and radiate heat efficiently. This will also lead to better overall temperature uniformity on the susceptor and wafer with lower temperature gradients producing less variation in crystal growth. Additionally, TaC offers exceptional oxidation resistance, which will ensure emissivity remains consistent during long-term operations, ensuring accurate temperature calibration and repeatable process performance.

TaC Coating Pedestal Supporter has high mechanical durability, lending to extended operational life. The CVD coating process, specifically, creates a solid molecular bond between the TaC layer and the graphite substrate to prevent delamination, cracking, or peeling from thermal stress. It is therefore a component benefiting from hundreds of high-temperature cycles without degradation.