- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

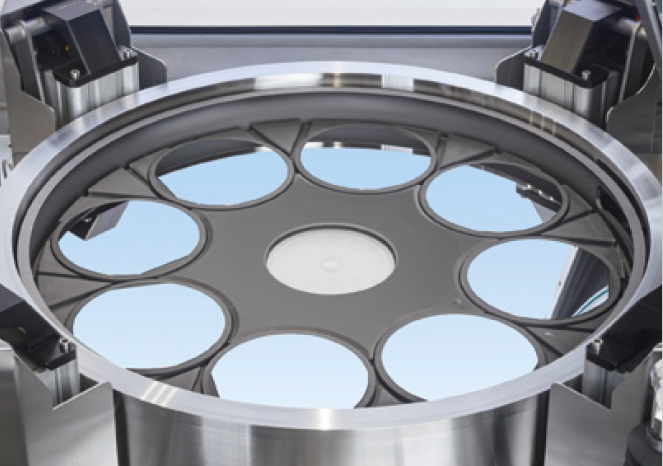

TaC Coated Planetary Plate

Semicorex TaC Coated Planetary Plate is a high-precision component designed for MOCVD epitaxial growth, featuring planetary motion with multiple wafer pockets and optimized gas flow control. Choosing Semicorex means accessing advanced coating technology and engineering expertise that deliver exceptional durability, purity, and process stability for the semiconductor industry.*

Send Inquiry

The Semicorex TaC Coated Planetary Plate serves as a key component within MOCVD reactors, exhibiting a planetary design characterized by numerous wafer pockets arranged along its surface. These pockets are specifically created to reliably accommodate the wafers during the growth phase of any epitaxial layer, stabilizing substrate wafers and minimizing substrate movement under elevated process temperatures. The exact pocket geometry provides consistent wafer placement that is important for uniform thickness of epitaxial layers and uniformity levels of substrate defects for all wafers grown during the same process.

An important design aspect of the planetary plate, once again, is the engineered dispersion of fine gas flow holes along the surface of the plate. These holes are carefully designed and strategically positioned specifically to meter the flow of precursor gases in the reactor, so uniform gas dispersion and even deposition is achieved among each wafer. In any MOCVD process, aspects of gas dynamics are critical in determining film qualities, thickness uniformity, and overall device performance. The optimized hole design on the TaC Coated Planetary Plate ensures that all wafers experience the same process conditions, which provides an optimal way to improve yield and reproducibility.

The TaC (tantalum carbide) coating further extends the performance and life of the planetary plate. Tantalum carbide is extremely hard, chemically inert, and thermally conductive, making it an excellent coating for extreme MOCVD environments. During epitaxy, the components in the reactor will encounter high temperatures, reactive precursor gases, and plasma exposure. The TaC coating serves as a robust barrier to corrosion, oxidation, and particle generation to result in a significant extension of the planetary plate life than an uncoated or conventionally coated plate.

The TaC Coated Planetary Plate's longevity and durability make it a cost-effective choice for MOCVD systems. The durable TaC layer can withstand repeated thermal cycling and exposure to extreme process gases while maintaining structural integrity and stability of performance while operating over extended timeframes.