- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

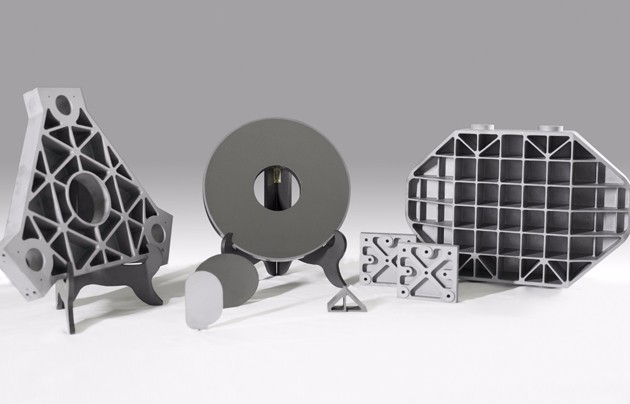

Silicon Carbide Scanning Mirrors

Semicorex Silicon Carbide Scanning Mirrors deliver exceptional precision, speed, and stability for the most demanding optical scanning applications. Choose Semicorex for unmatched expertise in SiC engineering, offering tailored geometries, premium coatings, and proven reliability in high-performance optical systems.*

Send Inquiry

Semicorex Silicon Carbide scanning mirrors are the next generation of high performance optical devices. Developed for the accelerated world of scanning, the mirrors provide the latest generation of beams steering and scanning capabilities for applications requiring very high speed, high degree of stability, and precision. Silicon carbide scanning mirrors have unique attributes due to their advanced ceramic manufacturing - the mirrors are very light, but have good mechanical and thermal properties. As such, they are considered ideal for high accuracy optical systems in industries such as advanced lithography, space-based observation, laser scanning or high-speed/real-time imaging.

A key aspect of the functionality of silicon carbide scanning mirrors is developing an optimum specific stiffness that meets the requirements of high-performance scanning. The low density and high elastic modulus provide a high level of stiffness, therefore maintaining the structural properties while moving through very high accelerations and dynamic movement. The greater the rigidity the lower the deformation when subject to very high loads, ensuring less optical distortion when imaging requires precise positioning at high speeds. In high-frequency scanners, the mirror's rigidity will improve the resolution and settling time directly.

Another specific property is the hardness of SiC. Hardness is defined as the ability of a material to resist surface damage, scratches, or wear. Increased hardness means a long operational life - even in harsh conditions with abrasive particles, and repeat cleaning. The high hardness also enables the mirrors to maintain their surface accuracy over extended usage cycles, preserving optical performance and reducing maintenance requirements.

Thermal management is another characteristic where silicon carbide shines. Because of high thermal conductivity, SiC can dissipate heat build-up from high power laser beams or from thermal environmental changes. This will help minimize thermal gradients that could create mirror deformation or misalignment, allowing consistent performance during long operational use. Vertex's high thermal stability SiC minimizes expansion/contraction with temperature changes, thus maintaining optical alignment when dimensional stability in all environmental conditions is essential, which often includes work needed for space telescopes or semiconductor lithography systems.

To facilitate performance and possibilities around its application, there are many surface coating options available. For instance, using a CVD SiC coating can improve surface uniformity, hardness, and weatherability. While silicon coatings allow for a better reflective interface for additional optical coatings to be deposited, such as the mirror surface itself, and provide opportunities for optimization depending on specific wavelength ranges, laser power levels and atmospheric conditions. You can ensure the mirror (for example) achieves the specific optical and durability requirement of its intended application with these additional surface coatings.

Another significant benefit of silicon carbide scanning mirrors is customization, including shape and geometry. Mirrors can be customized to be flat, spherical, and aspherical surfaces and high accuracy in shape is generally expected depending on the optical design. By incorporating lightweighted back structures, the mass of the mirrors can be further reduced without any loss of stiffness, allowing for quicker scanning and faster system reaction time. All of these features provide opportunities for individualized shaping, finishing, and coatings for each mirror depending on the optical and mechanical needs of the application.

Silicon carbide scanning mirrors are particularly advantageous in space-based optical systems, where mass savings, rigidity and thermal stability help ensure survival as well as performance in orbit. In lithography, the dimensional stability and high stiffness characteristics of SiC scanning mirrors provide nanometer-level positions that are critical for semiconductor manufacturing. In high-powered laser scanning systems, SiC's heat dispersing qualities and durability of a surface provide long-term stability over time and minimal distortion.

Semicorex Silicon carbide scanning mirrors provide an unbeatable combination of lightweight construction, high stiffness, high hardness, high thermal conductivity and thermal stability. The unique options of customizable shapes, precision surface finish, and innovative coatings including CVD SiC and silicon open doors and add performance characteristics and reliability for today's most demanding optical scanning applications.