- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

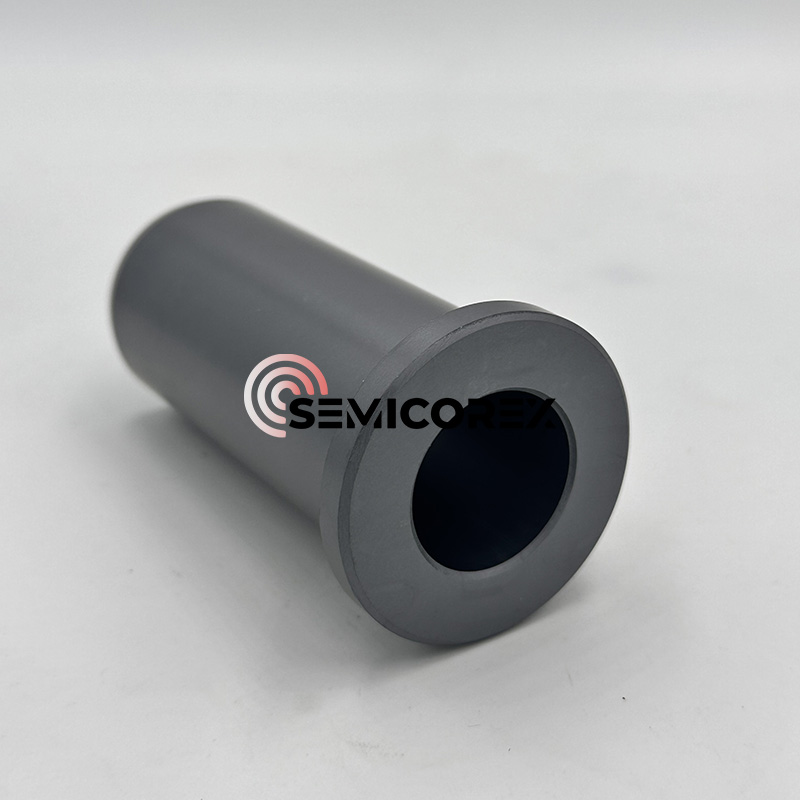

SiC Sleeves

Semicorex SiC Sleeves are the ideal components for the widely pump applications including the industrial, chemical processing, water, home appliance and automotive markets. Semicorex is specialized in Silicon Carbide ceramic products with high quality and cost-efficient solutions.*

Send Inquiry

Semicorex Sealed Ceramic Sleeve consists of a solid block made of silicon carbide (SiC), designed specifically for use in rotating equipment and mechanical seals, which has exceptional wear resistance and chemical resistance, making it a su

perior material for manufacturing sleeves for such purposes. Due to its high degree of hardness, low coefficient of friction, and extreme chemical inertness, SiC is the best choice of material for the fabrication of these products.

perior material for manufacturing sleeves for such purposes. Due to its high degree of hardness, low coefficient of friction, and extreme chemical inertness, SiC is the best choice of material for the fabrication of these products.

Compared to alumina ceramic and metallic coated materials, SiC provides an improved coefficient of friction, leading to increased self-lubricating properties, and greater stability at high speeds and in extreme environmental conditions.

SiC is unique because it can withstand extreme environments where both high pressures (P) and high sliding velocities (V) are present due to the potential failure caused by extreme friction and heat. By combining SiC with graphite, SiC sleeve surfaces maintain lower temperatures and reduced wear properties than they would with other materials, providing greater reliability and consistency of function over a long term. In summary, SiC sleeves can benefit from high-speed, continual operation and frequent start/stop cycles.

Silicon Carbide ceramic is the ideal material in manufacturing seal parts, it can be partner with graphite material, its coefficient of friction is lower than Alumina ceramic and hard alloy. It has an excellent self-lubricating performance. Therefore it can used for high PV value, making seals longer life span and higher working stability, especially used in applications involving the transport of strong acids and alkalis. The life span of SiC ceramic is about 3 to 5 times of Alumina ceramic. It is similar to hard alloy, so it is often used as a substitute for cemented carbide, especially in the case of handheld spray guns.

Ceramics made from silicon carbide are also highly resistant to chemical attack; as a result, SiC sleeves are commonly used in applications that involve working with very aggressive alkaline and acidic environments as well as other highly corrosive chemical systems. Unlike most metals that experience substantial corrosion or degradation over time due to chemical exposure, silicon carbide remains chemically inert and structurally stable when exposed to aggressive fluids for prolonged periods of time. Because of this outstanding property, SiC sleeves ideally serve as seals in chemical processing, petrochemical systems, wastewater treatment and other industrial applications where chemical resistance is considered essential. The use of SiC sleeves in these types of extreme operating environments, provides significant reductions in risk associated with leakage, seal failure and unanticipated down-time due to maintenance.

Silicon carbide ceramic typically lasts three to five times longer than alumina ceramic under similar conditions, therefore providing increased durability and decreased frequency of maintenance, along with a dramatic reduction in total planned and unplanned costs associated with the use of ceramics. Additionally, cemented carbide and silicon carbide are very similar with respect to wear resistant properties and structural integrity; thus, silicon carbide is becoming an increasingly popular replacement for cemented carbide in many applications, as it provides similar performance characteristics with additional advantages such as increased chemical stability and in some instances, reduced weight.

Excellent performance under heavy mechanical loads is guaranteed by silicon carbide's unique microstructure due to its dimensional stability and resistance to deformation over time. Precision manufacturing combined with advanced ceramic machining methods allow for extremely tight tolerances and highly polished surfaces necessary to produce optimal sealing performance of SiC sleeves. The fitted sleeves provide optimal sealing surfaces within mechanical seal assemblies (pumps, valves, rotating equipment) while maintaining optimal contact conditions and eliminating instability or uneven wear from vibration or other forms of dynamic loading.

SiC sleeves are an effective and economical choice for a variety of industrial applications: chemical engineering, surface treatment, fluid handling, precision equipment manufacture, etc. SiC sleeves provide longer usability, lower coefficient of friction, superior self-lubrication when used with graphite, excellent resistance to chemicals, and much longer serviceable life than alumina ceramic materials or cemented carbide products. Using silicon carbide sleeves, equipment manufacturers and users will benefit from improved reliability, increased maintenance intervals, and enhanced operating performance even in the harshest operating conditions.