- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China LED Epitaxial Wafers Manufacturers, Suppliers, Factory

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for LED Epitaxial Wafers,tantalum carbide tac,tantalum carbide coatings,TaC coated,MOCVD, Should you pursuit the Hi-quality, Hi-stable, Aggressive price tag parts, business name is your most effective choice!

LED Epitaxial Wafers, Our items have won an excellent reputation at each of the related nations. Because the establishment of our firm. now we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Hot Products

ICP Plasma Etching System for PSS Process

Choose Semicorex's ICP Plasma Etching System for PSS Process for high-quality epitaxy and MOCVD processes. Our product is engineered specifically for these processes, offering superior heat and corrosion resistance. With a clean and smooth surface, our carrier is perfect for handling pristine wafers.Plasma Processing Focus Ring

Semicorex Plasma processing focus ring is specially designed to meet the high demands of plasma etch processing in the semiconductor industry. Our advanced, high-purity Silicon Carbide Coated Components are built to withstand extreme environments and are suitable for use in various applications, including silicon carbide layers and epitaxy semiconductors.4" 6" 8" N-type SiC Ingot

Semicorex provides N-type SiC ingot with 4 inches, 6 inches and 8 inches. We have been manufacturer and supplier of wafers for many years. Our 4" 6" 8" N-type SiC Ingot has a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.PBN/PG Heaters

Semicorex PBN/PG Heaters (Pyrolytic Boron Nitride/Pyrolytic Graphite) are engineered from advanced Boron Nitride ceramic materials, meticulously crafted to withstand extreme temperatures exceeding 1700°C. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Rigid Felt with Glass-like Carbon Coating

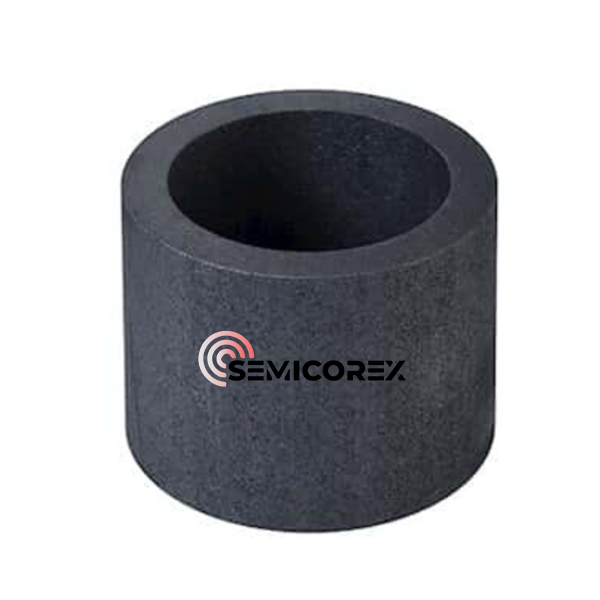

Semicorex Rigid Felt with Glass-like Carbon Coating is a high-performance insulation material that combines the durability of carbon fiber felt with a scratch-resistant, dust-reducing glass-like carbon coating. Semicorex’s expertise in advanced coating technologies ensures exceptional durability and cleanliness, meeting the demands of high-temperature and precision-sensitive applications.*TaC Coated Crucibles

Semicorex TaC Coated Crucibles are high-performance container designed for extreme temperature applications, suitable for both metal melting and advanced semiconductor processes. Choosing Semicorex means gaining access to cutting-edge coating technology and engineering expertise that deliver exceptional purity, durability, and stability in the most demanding environments.*