- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Gas Injection System For MOCVD Manufacturers, Suppliers, Factory

Our organization sticks for the principle of "Quality will be the life of your business, and name may be the soul of it" for Gas Injection System For MOCVD,Inlet Seal Ring,Inlet Connection Ring,Inlet Tube Ring,Inlet Chamber Ring, Leading the trend of this field is our persistent objective. Supplying first class solutions is our intention. To create a beautiful upcoming, we wish to cooperate with all close friends in the home and overseas. Should you have got any interest in our products and solutions, remember to never wait to call us.

Gas Injection System For MOCVD, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we're doing for. We have been an absolutely reliable partner for you personally in China. Of course, other services, like consulting, can be offered too.

Hot Products

RTP/RTA SiC Coating Carrier

Semicorex RTP/RTA SiC Coating Carrier is engineered to withstand the toughest conditions of the deposition environment. With its high heat and corrosion resistance, this product is designed to provide optimal performance for epitaxial growth. The SiC coated carrier has a high thermal conductivity and excellent heat distribution properties, ensuring reliable performance for RTA, RTP, or harsh chemical cleaning.Carbon and Graphite Soft Felt

Semicorex Carbon and graphite soft felt is a specialized material that is made from carbon fibers or graphite fibers that are intertwined to form a soft, flexible, and porous structure. It is commonly used in various industrial applications due to its unique properties.SiC Parts Abdeck Segmenten

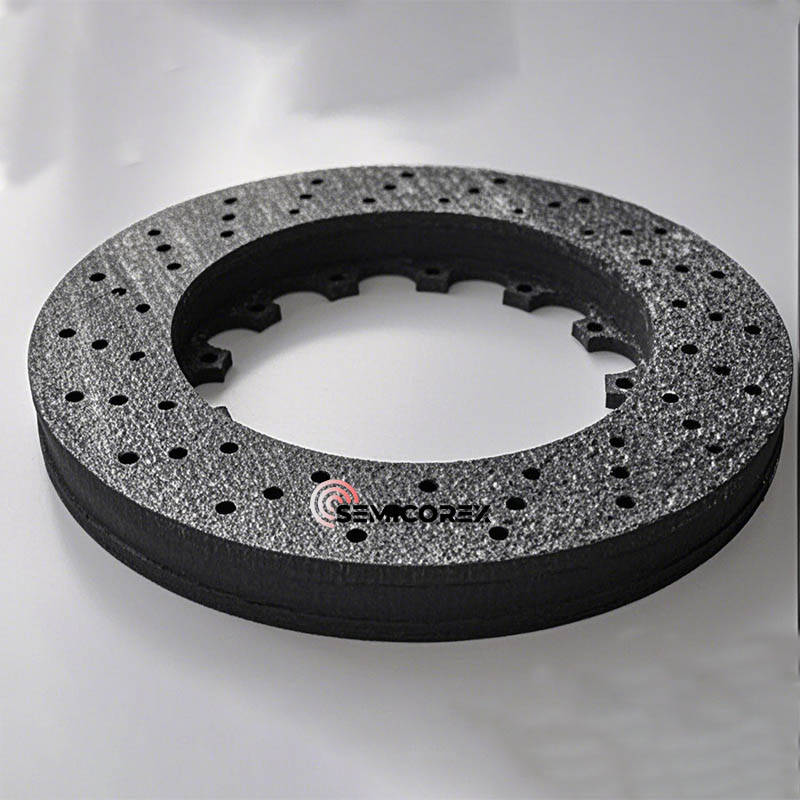

Semicorex SiC Parts Abdeck Segmenten, a crucial component in semiconductor device manufacturing that redefines precision and durability. Crafted from SiC coated graphite, these small yet essential parts play a pivotal role in advancing semiconductor processing to new levels of efficiency and reliability.SiC Seal Parts

Semicorex SiC seal parts, or Silicon Carbide seal parts, represent a cutting-edge and highly efficient solution for various industrial applications where sealing integrity is paramount. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.AlN Single Crystal Wafer

Semicorex AlN single crystal wafer is a cutting-edge semiconductor substrate designed for high-power, high-frequency, and deep ultraviolet (UV) applications. Choosing Semicorex ensures access to industry-leading crystal growth technology, high-purity materials, and precise wafer fabrication, guaranteeing superior performance and reliability for demanding applications.*Impregnated Graphite Rods

Semicorex Impregnated Graphite Rods are precious machined, they are made of high quality impregnated graphite, widely used in the mechanical industry. Semicorex is a top-notch company in China that delivers high-quality graphite products.*