- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China epitaxial layer growth Manufacturers, Suppliers, Factory

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for epitaxial layer growth,epitaxial silicon growth,gan epitaxial growth,epitaxy of semiconductors,graphite susceptor, Welcome any inquiry to our firm. We will be happy to ascertain helpful business enterprise relationships along with you!

epitaxial layer growth, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

Hot Products

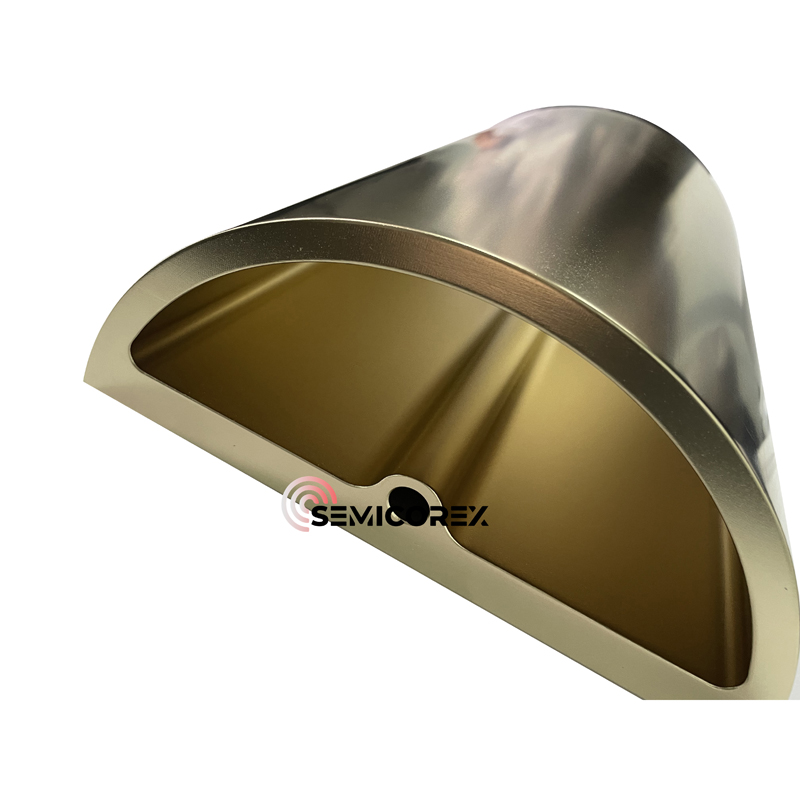

SiC Coated Epitaxial Reactor Barrel

The Semicorex SiC Coated Epitaxial Reactor Barrel is a top-quality graphite product coated with high-purity SiC. Its excellent density and thermal conductivity make it an ideal choice for use in LPE processes, providing exceptional heat distribution and protection in corrosive and high-temperature environments.SiC-Coated Barrel Susceptor

With its high melting point, oxidation resistance, and corrosion resistance, the Semicorex SiC-Coated Barrel Susceptor is the perfect choice for use in single crystal growth applications. Its silicon carbide coating provides exceptional flatness and heat distribution properties, ensuring reliable and consistent performance in even the most demanding high-temperature environments.Silicon Carbide Epitaxy Susceptor

Semicorex is a large-scale manufacturer and supplier of Silicon Carbide Epitaxy Susceptor in China. We focus on semiconductor industries such as silicon carbide layers and epitaxy semiconductor. Our products have a good price advantage and cover many of the European and American markets. We look forward to becoming your long-term partner.SiC Wafer Tray

The Semicorex SiC Wafer Tray is a vital asset in the Metal-Organic Chemical Vapor Deposition (MOCVD) process, meticulously designed to support and heat semiconductor wafers during the essential step of epitaxial layer deposition. This tray is integral to semiconductor device manufacturing, where the precision of layer growth is of utmost importance. We at Semicorex are dedicated to manufacturing and supplying high-performance SiC Wafer Tray that fuse quality with cost-efficiency.SiC Wafer Susceptors for MOCVD

The Semicorex SiC Wafer Susceptors for MOCVD are a paragon of precision and innovation, specifically crafted to facilitate the epitaxial deposition of semiconductor materials onto wafers. The plates’ superior material properties enable them to withstand the stringent conditions of epitaxial growth, including high temperatures and corrosive environments, making them indispensable for high-precision semiconductor manufacturing. We at Semicorex are dedicated to manufacturing and supplying high-performance SiC Wafer Susceptors for MOCVD that fuse quality with cost-efficiency.SiC Coating Flat Part

Semicorex SiC Coating Flat Part is a SiC-coated graphite component essential for uniform airflow conduction in the SiC epitaxy process. Semicorex delivers precision-engineered solutions with unmatched quality, ensuring optimal performance for semiconductor manufacturing.*