- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramic Sintering Furnace Manufacturers, Suppliers, Factory

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Ceramic Sintering Furnace,MOCVD Ceiling Plate,MOCVD Chamber Lids,MOCVD Cover Plate,Silicon Carbide Ceramic Lid, For more information and facts, you should never wait to make contact with us. All inquiries from you may be highly appreciated.

Ceramic Sintering Furnace, Since our establishment, we keep on improving our products and solutions and customer service. We have been able to supply you with a wide range of high quality hair items at competitive prices. Also we can produce different hair merchandise according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

Hot Products

SiC-Coated Barrel Susceptor

With its high melting point, oxidation resistance, and corrosion resistance, the Semicorex SiC-Coated Barrel Susceptor is the perfect choice for use in single crystal growth applications. Its silicon carbide coating provides exceptional flatness and heat distribution properties, ensuring reliable and consistent performance in even the most demanding high-temperature environments.SiC Coated PSS Etching Carrier

Wafer carriers used in epixial growth and wafer handling processing must endure high temperatures and harsh chemical cleaning. Semicorex SiC Coated PSS Etching Carrier engineered specifically for these demanding epitaxy equipment applications. Our products have a good price advantage and cover many of the European and American markets. We look forward to becoming your long-term partner in China.CVD TaC Coating Ring

Semicorex CVD TaC Coating Ring is a high-performance component designed for demanding applications requiring exceptional wear resistance, thermal stability, and chemical inertness. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.TaC-Coating Crucible

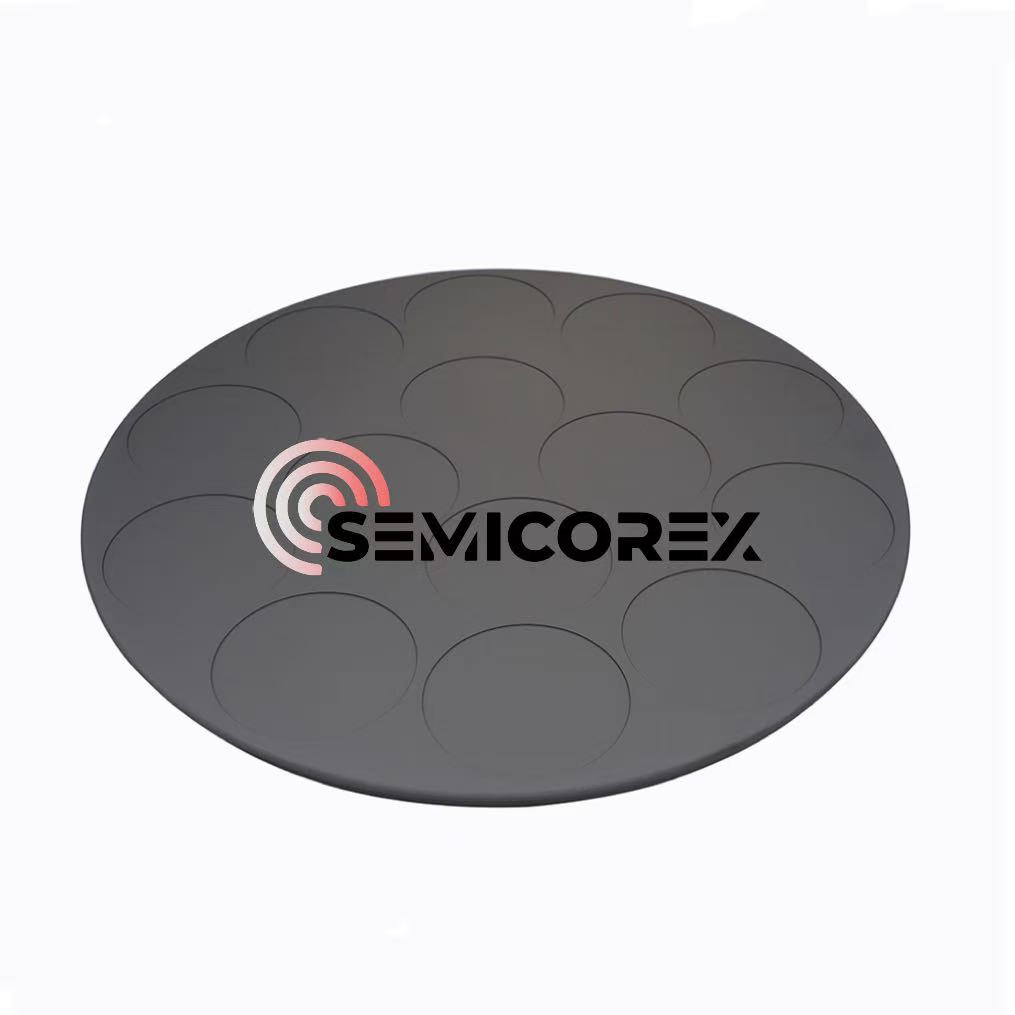

Semicorex TaC-Coating Crucible has emerged as an essential tool in the pursuit of high-quality semiconductor crystals, enabling advancements in material science and device performance. The TaC-Coating Crucible's unique combination of properties makes them ideally suited for the demanding environments of crystal growth processes, offering distinct advantages over traditional materials.**SiC Disc Susceptor

Semicorex introduces its SiC Disc Susceptor, designed to elevate the performance of Epitaxy, Metal-Organic Chemical Vapor Deposition (MOCVD), and Rapid Thermal Processing (RTP) equipment. The meticulously engineered SiC Disc Susceptor provides with properties that guarantee superior performance, durability, and efficiency in high-temperature and vacuum environments.**SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.