- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

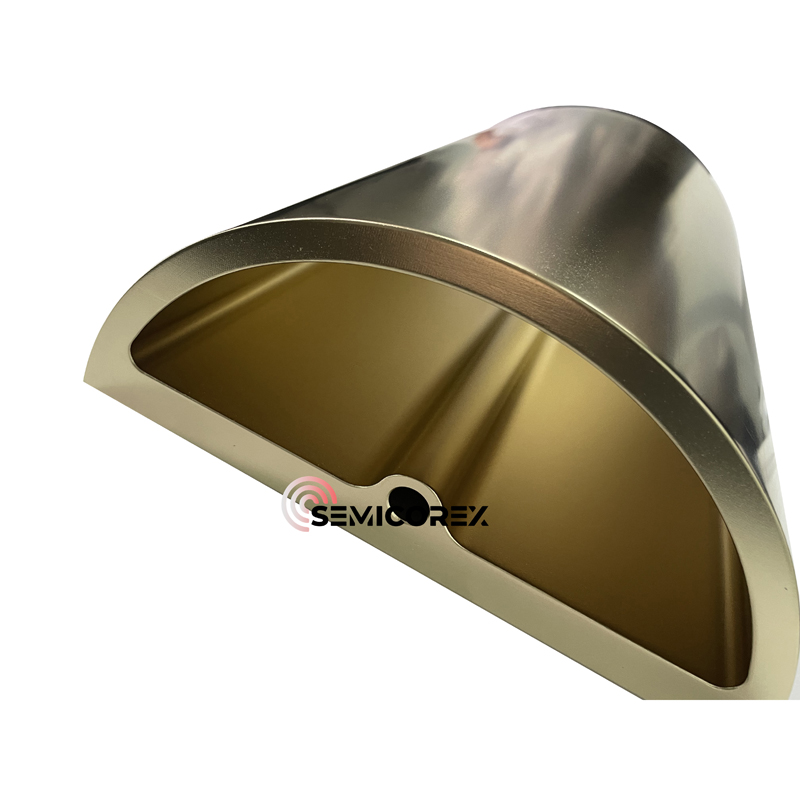

China Wafer Vacuum Sucker Manufacturers, Suppliers, Factory

To frequently enhance the administration program by virtue on the rule of "sincerely, very good faith and high-quality are the base of enterprise development", we widely absorb the essence of related products internationally, and consistently develop new products to fulfill the calls for of customers for Wafer Vacuum Sucker,Wafer Handling Equipment,Electrostatic Chuck Semiconductor,Silicon Wafer Handling Tools,Sic Chuck, With our rules of " organization track record, partner trust and mutual benefit", welcome all of you to function together , improve jointly.

Wafer Vacuum Sucker, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Hot Products

Inductively Heated Barrel Epi System

If you need a graphite susceptor with exceptional thermal conductivity and heat distribution properties, look no further than the Semicorex Inductively Heated Barrel Epi System. Its high-purity SiC coating provides superior protection in high-temperature and corrosive environments, making it the ideal choice for use in semiconductor manufacturing applications.Silicon Etch Plate for PSS Etching Applications

Semicorex's Silicon Etch Plate for PSS Etching Applications is a high-quality, ultra-pure graphite carrier that is specifically designed for epitaxial growth and wafer handling processes. Our carrier can withstand harsh environments, high temperatures, and harsh chemical cleaning. The silicon etch plate for PSS etching applications has excellent heat distribution properties, high thermal conductivity, and is cost-effective. Our products are widely used in many European and American markets, and we look forward to becoming your long-term partner in China.Barrel Susceptor Silicon Carbide Coated Graphite

Semicorex Barrel Susceptor Silicon Carbide Coated Graphite is a specialized component designed for use in the epitaxy process, particularly in carrying wafers. Contact us today to learn more about how we can help you with your semiconductor wafer processing needs.TaC Coated Graphite Parts

Semicorex TaC Coated Graphite Parts are precision-crafted components that are specially designed to withstand the demanding environment of semiconductor processing. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Silicon Carbide Tray

Semicorex Silicon Carbide Tray is built to withstand extreme conditions while ensuring remarkable performance. It plays a crucial role in the ICP etching process, semiconductor diffusion, and the MOCVD epitaxial process.SiC Coated Wafer Carriers

Semicorex SiC Coated Wafer Carriers are high-purity graphite susceptors coated with CVD silicon carbide, designed for optimal wafer support during high-temperature semiconductor processes. Choose Semicorex for unmatched coating quality, precision manufacturing, and proven reliability trusted by leading semiconductor fabs worldwide.*