- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China SiC chuck Manufacturers, Suppliers, Factory

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of SiC chuck,porous ceramic,Microporous SiC,wafer chuck,vacuum chuck, Looking to the long run, a lengthy way to go, regularly striving to become the all employees with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced merchandise, good quality first-class modern company and work hard!

SiC chuck, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products and solutions. Our advantage is full category, high quality and competitive price! Based on that, our goods win a high admiration both at home and abroad.

Hot Products

ICP Plasma Etching System for PSS Process

Choose Semicorex's ICP Plasma Etching System for PSS Process for high-quality epitaxy and MOCVD processes. Our product is engineered specifically for these processes, offering superior heat and corrosion resistance. With a clean and smooth surface, our carrier is perfect for handling pristine wafers.SiC-Coated ICP Component

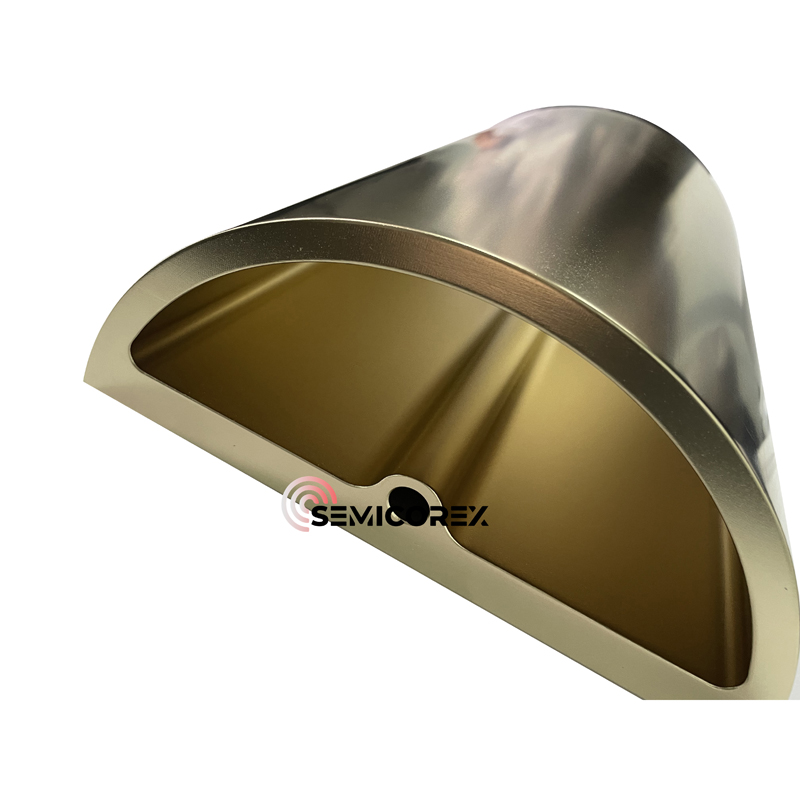

Semicorex's SiC-Coated ICP Component is designed specifically for high-temperature wafer handling processes such as epitaxy and MOCVD. With a fine SiC crystal coating, our carriers provide superior heat resistance, even thermal uniformity, and durable chemical resistance.Second Half Parts for Lower Baffles in Epitaxial Process

Semicorex Second Half Parts for Lower Baffles in Epitaxial Process, meticulously engineered components designed to revolutionize the performance of your semiconductor devices. Specifically tailored for the intake system of LPE reactors, these semi-cylindrical fittings play a pivotal role in enhancing the epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Guide Ring

Semicorex SiC Guide Ring is engineered to optimize the single crystal growth process. Its exceptional thermal conductivity ensures uniform heat distribution, contributing to the formation of high-quality crystals with enhanced purity and structural integrity. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.SiC Wafer Tray

The Semicorex SiC Wafer Tray is a vital asset in the Metal-Organic Chemical Vapor Deposition (MOCVD) process, meticulously designed to support and heat semiconductor wafers during the essential step of epitaxial layer deposition. This tray is integral to semiconductor device manufacturing, where the precision of layer growth is of utmost importance. We at Semicorex are dedicated to manufacturing and supplying high-performance SiC Wafer Tray that fuse quality with cost-efficiency.SiC Coated Graphite Trays

Semicorex SiC Coated Graphite Trays are high-performance carrier solutions specifically designed for AlGaN epitaxial growth in the UV LED industry. Choose Semicorex for industry-leading material purity, precision engineering, and unmatched reliability in demanding MOCVD environments.*