- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

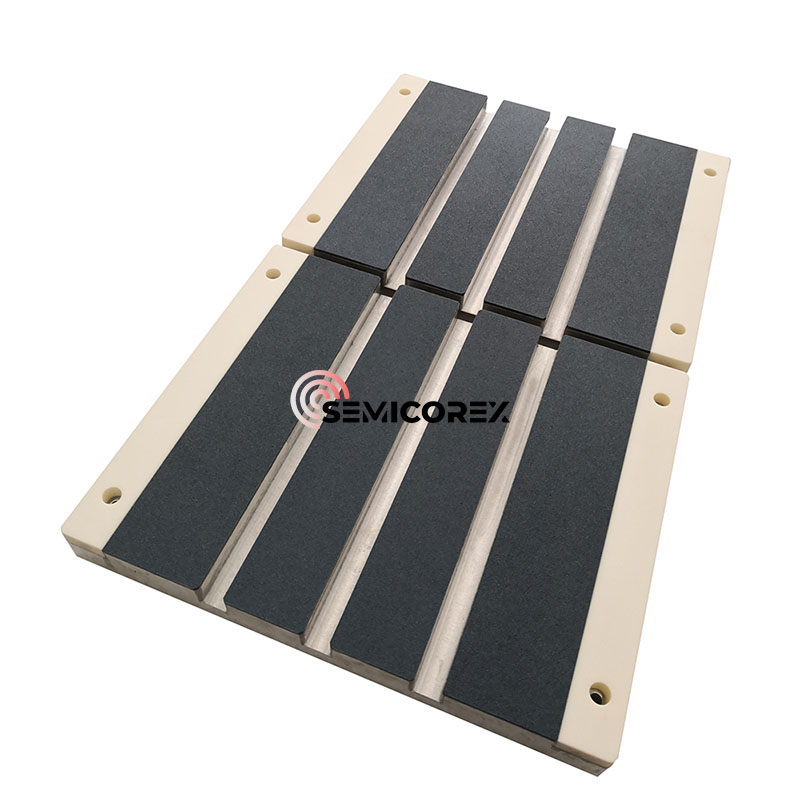

Porous SiC Vacuum Chuck

Semicorex Porous SiC Vacuum Chuck is designed for precise and reliable wafer handling, offering customizable material options to meet a wide range of semiconductor processing needs. Choose Semicorex for its commitment to high-quality, durable solutions that deliver optimal performance and efficiency in every application.*

Send Inquiry

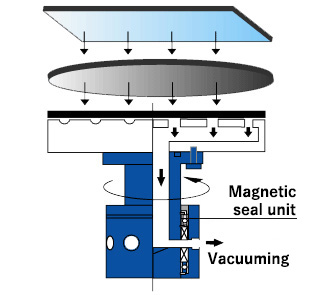

Semicorex Porous SiC Vacuum Chuck represents a handling solution aimed at achieving accurate, stable positioning of wafers during all stages of semiconductor processing. This vacuum chuck holds excellent grip for wafer handling and substrate alignment applications, thereby enhancing both reliability and performance. The base material choices—SUS430, aluminum alloy 6061, dense alumina ceramic, granite, and silicon carbide ceramic—offer the user flexibility to choose the optimal material according to individual requirements in thermal performance, mechanical properties, or weight.

Better Material Choice: The bottom of the Porous SiC Vacuum Chuck can be changed with different materials to suit various needs:

- SUS430: A cheap option that resists rust well for common uses.

- Aluminum Alloy 6061: Gives a mix of strength, light weight, and great workability, making it good for regular wafer handling.

- Dense Alumina Ceramic (99% Al2O3): Provides excellent thermal stability and high hardness, suitable for high-temperature or precision applications.

- Granite: Known for its exceptional flatness and stability, granite provides low thermal expansion, ideal for applications requiring high precision.

- Silicon Carbide Ceramic: Known for its high thermal conductivity, chemical resistance, and durability, SiC is ideal for high-performance environments where extreme conditions are encountered.

High Precision Flatness: The Porous SiC Vacuum Chuck ensures superior flatness, with precision varying based on the material used. The material ranking from highest to lowest flatness precision is:

Granite and Silicon Carbide Ceramic: Both materials offer high precision flatness, ensuring wafer stability even in the most demanding processing environments.

Dense Alumina (99% Al2O3): Slightly less flatness compared to granite and SiC, but still offers good accuracy for general semiconductor applications.

Aluminum Alloy 6061 and SUS430: Provide slightly lower flatness precision but are still highly reliable for wafer handling in less demanding applications.

Weight Variations for Specific Needs: The Porous SiC Vacuum Chuck allows users to choose from a variety of material options based on weight requirements:

Aluminum Alloy 6061: The lightest material choice, offering easy handling and transport.

Granite: A heavier base material that provides high stability and minimizes vibrations during processing.

Silicon Carbide Ceramic: Has a moderate weight, offering a balance of durability and thermal conductivity.

Dense Alumina Ceramic: The heaviest option, ideal for applications where stability and high thermal resistance are prioritized.

High Durability and Performance: The Porous SiC Vacuum Chuck is engineered for long-lasting performance, capable of withstanding extreme temperature variations and the wear associated with semiconductor processing. The silicon carbide ceramic variant is particularly beneficial for high-temperature and chemically aggressive environments due to its exceptional resistance to thermal expansion and corrosion.

Cost-Effective Solutions: With multiple material options, the Porous SiC Vacuum Chuck provides a cost-effective solution that can be tailored to different budgets and application requirements. For general applications, aluminum alloy and SUS430 are cost-efficient while still offering satisfactory performance. For more demanding environments, the granite or SiC ceramic options provide enhanced performance and durability.

Applications:

The Porous SiC Vacuum Chuck is primarily used in the semiconductor industry for wafer handling, including in processes such as:

- Wafer Dicing and Cutting

- Photovoltaic Manufacturing

- MOCVD and CVD Epitaxy Growth

- Ion Implantation

- Oxidation and Diffusion Processes

Semicorex’s Porous SiC Vacuum Chuck stands out for its precision, versatility, and durability. Whether you require lightweight solutions for general handling or advanced materials for high-performance semiconductor processes, our product offers a wide range of options to meet your needs. Manufactured with the highest quality standards, our vacuum chucks ensure reliable and efficient wafer handling for various applications, delivering consistent results in both standard and specialized processes.

For industries where wafer stability and precise handling are crucial, the Porous SiC Vacuum Chuck offers an ideal solution. With its selection of materials, high precision, and superior durability, it is the perfect choice for a wide range of semiconductor processes.